1. I understand your theory behind point 1, but it doesn't have much impact in practice. I replaced the 1K with a 33K and see no change in the <8V output level. I then tried 330K and see a very slight rise to around 8V exactly. I pushed it even further to 33M and the output still doesn't surpass 8V.

2. I understand why this is best practice. That said, connecting the pin 5 bypass capacitor directly between pin 1 and pin 5 with short leads has no effect on the transient or rest of the waveform. In fact, disconnecting this capacitor entirely has only a tiny effect on the frequency of the waveform and no impact on the transient.

3. Unfortunately, I don't have a 10uF tantalum on hand. I tried a 10uF electrolytic + 0.1uF ceramic connected directly between pins 1 and 8 with short leads. The higher frequencies change a bit, but the large lower frequency hump is still there.

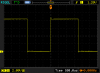

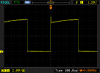

Let me show you what I mean. Here's the falling edge of the square wave:

View attachment 26420

The transient at the bottom of this edge looks like typical ringing.

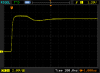

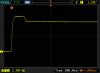

Now here's the rising edge with the same scope settings:

View attachment 26421

That hump is lower frequency than the ringing. All of the good hygiene tips I've received are helping to smooth the high frequencies off the hump, but nothing so far has affected the hump itself.

Furthermore, the top of the hump is 9V, which is Vcc. That's why I think the hump may be a feature of the 555 itself. It looks as though it's trying to drive the ouput to 9V and momentarily gets there, but then falls back and stabilizes at 8V.