Xeno,

I have attempted to read the whole thread from the beginning, then address the more interesting issues outstanding. Please forgive me if I failed to take note of something I missed along the way.

Not all "555" timers are the same. Even bipolar parts vary among manufacturers and dates of manufacture. Even if the specifications are identical. CMOS parts are quite different from the bipolar original, and the CMOS specifications vary quite a bit among the various manufacturers. So it is often very useful to know the exact part number, manufacturer, and possibly even the date code for the part under discussion.

And, of course, it is a courtesy to provide a link to a data sheet for the version of the part you are using.

I found an old Signetics data sheet here: http://www.datasheetarchive.com/dl/Scans-005/Scans-00107395.pdf

And a more readable ST data sheet here: http://www.datasheetarchive.com/dl/Datasheets-EC1/DSAQ00222376.pdf

I hope I understand correctly that the "555" in question here is in fact a bipolar part, not CMOS.

It also appears that the part used by dorke to research the problem and post the nice Tek465 screen shots was a CMOS version. The bipolar parts will not produce an output = Vcc, even with no load. Guess that should be Vdd! I wonder how his part was marked.

I think that the tall narrow spike overshoot was probably due to spikes on Vcc caused by inductance in the Vcc wiring. Vcc at the device pins was actually spiking up above the nominal DC value when the output stage switched. As already pointed out, the bipolar NE555 draws a big current spike from Vcc when the output stage switches. Both output transistors are on at once for a brief time. When this spike ends, any inductance in series with the Vcc source will briefly pull the Vcc pin higher than normal.

I don't think any tantalum capacitors are really required for bypass use in this circuit. A fairly large ceramic cap backed-up by an aluminum electrolytic should be good enough. The plastic breadboard renders any really good capacitor beside the point, anyway.

( Should add that I have had fairly good luck with these breadboards, but they are not good for everything. Circuits using a 555, an LM324 or an LM339 seem to do well enough. Perhaps an MC1458 or uA741. 7400 or 74LS00 logic is usually OK. Fast stuff, very low level audio, or RF circuits may produce very unexpected results.)

Once the breadboard circuit construction was cleaned up a bit, the remaining overshoot may be due to transistor storage time effects. The bipolar 555 is made using an analog process. The transistors are not optimized for fast switching. Storage times may be in the hundreds of nanoseconds.

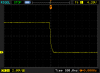

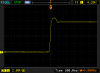

Here's that screen shot again, showing the 555 output pin transition from low to high.

It appears that the overshoot seen above reaches very close to the 9VDC Vcc, and lasts for 300ns to 350ns.

I think this overshoot may be due to the output transistor storage time.

This transistor (Q22) gets lots of base drive as the output pin moves high. Base drive is applied before the pull-down transistor, Q24, begins to turn off. Maximum base drive current continues to be applied to Q22 as the output pin rises. Once the pin reaches about 1.5V below Vcc, the base drive current falls rapidly, but the stored charge keeps Q22 turned-on for a short time. With a light load on the output pin, Q24 will pull the output close to Vcc until the Q24 storage time interval is over.

After the end of the Q22 storage time, Q22 falls out of saturation, the output pin then falls to the steady state value, about 1.5 volts below Vcc. Around this voltage level, the base drive for the transistor is restored and holds it there.

Again, these are quite slow transistors. They turn on more quickly than they turn off. So when the output is switching, lots of current is flowing through them between Vcc and GND, even before the output pin begins to move.

Using the output pin to drive the timing resistor is perfectly OK, as long as the output pin's limitations are taken into account.

If you look at the more complete data sheets, you will see that the output voltage versus current characteristics are not described by simple straight lines. And neither the high or low output voltage is right against the rail. And these voltages depend on the load on the output.

So timing that is dependent on the output pin voltage may not be as precise as you would like. But there is no inherent reason not to use the output pin in the timing circuit. Sometimes a pull-up resistor can help this work better.

It is entirely likely that most SPICE models fail to accurately model the behavior of the output pin.

As already suggested, a CMOS "555" may be a better choice for you. The CMOS parts generally have more symmetrical output pin characteristics, and will pull light loads very close to both supply rails.

Using the CMOS part, you can produce a nominal 50% squarewave output using just one resistor and one capacitor. No need for diodes, pull up resistors or other extra stuff.

Of course, due to device tolerances, the exact % will vary from device to device, and to some extent with temperature. And a heavy load on the output pin will change the timing.

When considering CMOS alternatives, some study of the data sheets is a very good idea. Specifications vary from one variety to another. Many have much lower maximum power supply voltage ratings than the original's 18V. Often the output currents are rated much lower, also.

Ted

I have attempted to read the whole thread from the beginning, then address the more interesting issues outstanding. Please forgive me if I failed to take note of something I missed along the way.

Not all "555" timers are the same. Even bipolar parts vary among manufacturers and dates of manufacture. Even if the specifications are identical. CMOS parts are quite different from the bipolar original, and the CMOS specifications vary quite a bit among the various manufacturers. So it is often very useful to know the exact part number, manufacturer, and possibly even the date code for the part under discussion.

And, of course, it is a courtesy to provide a link to a data sheet for the version of the part you are using.

I found an old Signetics data sheet here: http://www.datasheetarchive.com/dl/Scans-005/Scans-00107395.pdf

And a more readable ST data sheet here: http://www.datasheetarchive.com/dl/Datasheets-EC1/DSAQ00222376.pdf

I hope I understand correctly that the "555" in question here is in fact a bipolar part, not CMOS.

It also appears that the part used by dorke to research the problem and post the nice Tek465 screen shots was a CMOS version. The bipolar parts will not produce an output = Vcc, even with no load. Guess that should be Vdd! I wonder how his part was marked.

I think that the tall narrow spike overshoot was probably due to spikes on Vcc caused by inductance in the Vcc wiring. Vcc at the device pins was actually spiking up above the nominal DC value when the output stage switched. As already pointed out, the bipolar NE555 draws a big current spike from Vcc when the output stage switches. Both output transistors are on at once for a brief time. When this spike ends, any inductance in series with the Vcc source will briefly pull the Vcc pin higher than normal.

I don't think any tantalum capacitors are really required for bypass use in this circuit. A fairly large ceramic cap backed-up by an aluminum electrolytic should be good enough. The plastic breadboard renders any really good capacitor beside the point, anyway.

( Should add that I have had fairly good luck with these breadboards, but they are not good for everything. Circuits using a 555, an LM324 or an LM339 seem to do well enough. Perhaps an MC1458 or uA741. 7400 or 74LS00 logic is usually OK. Fast stuff, very low level audio, or RF circuits may produce very unexpected results.)

Once the breadboard circuit construction was cleaned up a bit, the remaining overshoot may be due to transistor storage time effects. The bipolar 555 is made using an analog process. The transistors are not optimized for fast switching. Storage times may be in the hundreds of nanoseconds.

Here's that screen shot again, showing the 555 output pin transition from low to high.

It appears that the overshoot seen above reaches very close to the 9VDC Vcc, and lasts for 300ns to 350ns.

I think this overshoot may be due to the output transistor storage time.

This transistor (Q22) gets lots of base drive as the output pin moves high. Base drive is applied before the pull-down transistor, Q24, begins to turn off. Maximum base drive current continues to be applied to Q22 as the output pin rises. Once the pin reaches about 1.5V below Vcc, the base drive current falls rapidly, but the stored charge keeps Q22 turned-on for a short time. With a light load on the output pin, Q24 will pull the output close to Vcc until the Q24 storage time interval is over.

After the end of the Q22 storage time, Q22 falls out of saturation, the output pin then falls to the steady state value, about 1.5 volts below Vcc. Around this voltage level, the base drive for the transistor is restored and holds it there.

Again, these are quite slow transistors. They turn on more quickly than they turn off. So when the output is switching, lots of current is flowing through them between Vcc and GND, even before the output pin begins to move.

Using the output pin to drive the timing resistor is perfectly OK, as long as the output pin's limitations are taken into account.

If you look at the more complete data sheets, you will see that the output voltage versus current characteristics are not described by simple straight lines. And neither the high or low output voltage is right against the rail. And these voltages depend on the load on the output.

So timing that is dependent on the output pin voltage may not be as precise as you would like. But there is no inherent reason not to use the output pin in the timing circuit. Sometimes a pull-up resistor can help this work better.

It is entirely likely that most SPICE models fail to accurately model the behavior of the output pin.

As already suggested, a CMOS "555" may be a better choice for you. The CMOS parts generally have more symmetrical output pin characteristics, and will pull light loads very close to both supply rails.

Using the CMOS part, you can produce a nominal 50% squarewave output using just one resistor and one capacitor. No need for diodes, pull up resistors or other extra stuff.

Of course, due to device tolerances, the exact % will vary from device to device, and to some extent with temperature. And a heavy load on the output pin will change the timing.

When considering CMOS alternatives, some study of the data sheets is a very good idea. Specifications vary from one variety to another. Many have much lower maximum power supply voltage ratings than the original's 18V. Often the output currents are rated much lower, also.

Ted