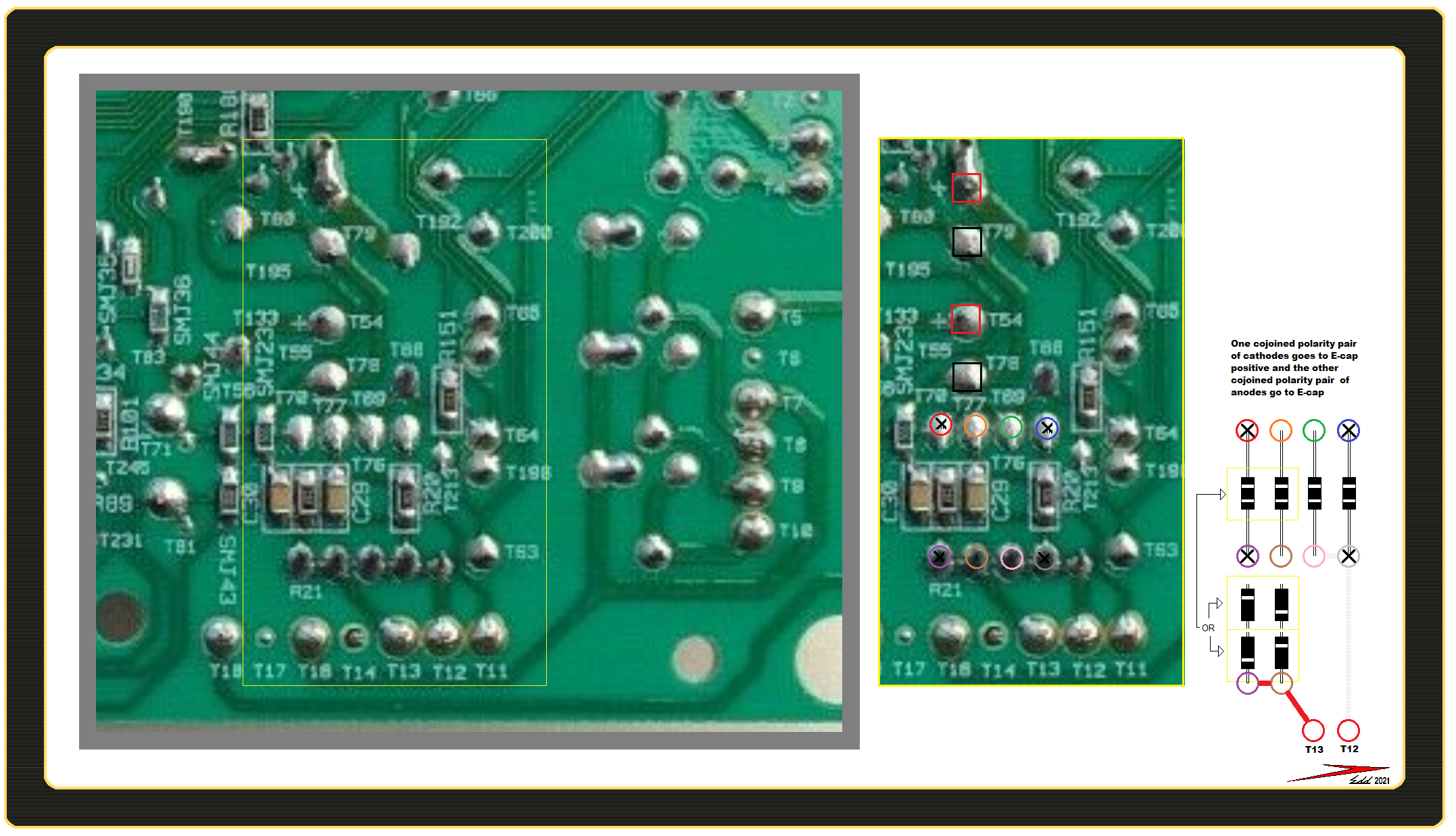

This Whirlpool Oven model RBD305PDB12 come on and goes off sometimes in months. So might work for several weeks then go off for months and then come back all of a sudden and work for a while again. I finally took out its Control Board and there is a carbon trace on it and where a diode mounts has damage. Please see the picture. I don't see any other damage on this board, pictures included. How can I repair this board? The board seems to have a little hole and I am not sure resoldering will be enough. I recently saw someone using super glue and baking soda as a repair for plastics. Would that work plus a resolder? Any help would be appreciated. Thank you.

https://drive.google.com/file/d/19GvLnyClx84ujM-7cRxCWANuRyn9FS-p/view?usp=sharing

https://drive.google.com/file/d/1Ywx5EK0WTTxYUL88ZLCvxEmwHQIa7PU3/view?usp=sharing

https://drive.google.com/file/d/1wdMgwNZxcWQZyEVgxO-1TsES3hmcHQT6/view?usp=sharing

https://drive.google.com/file/d/1Ox9ZA7RyF97rTQBy10Styc8CjNVgCTbE/view?usp=sharing

https://drive.google.com/file/d/19GvLnyClx84ujM-7cRxCWANuRyn9FS-p/view?usp=sharing

https://drive.google.com/file/d/1Ywx5EK0WTTxYUL88ZLCvxEmwHQIa7PU3/view?usp=sharing

https://drive.google.com/file/d/1wdMgwNZxcWQZyEVgxO-1TsES3hmcHQT6/view?usp=sharing

https://drive.google.com/file/d/1Ox9ZA7RyF97rTQBy10Styc8CjNVgCTbE/view?usp=sharing