What are you going to use this for? Electric fences put out a pulse about once a second and so give time for the victim to withdraw.

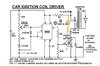

I need to simulate a running engine to get a speed signal to the ECU of my Old jaguar to see if the ECU triggers the injection in a nutshell ,I just need to trigger a coil that the ECU receive the 300V + voltage from the negative of the coil at its Terminal 18 , I need 150 HZ to have 900 Rpm on the V12.

snubber with a resistor will reduce the output, however if you insist, then put it across the transformer primary.

The snubber circuit is placed over the

Primary side of the Coil ,The Original circuit does not have it and then the circuit will run for 20 sec and the 555 is dead.

( think it the EMI of the Coil killing the 555)

I then calculated as per some simple snubber circuit calculations examples found on the net a circuit and placed it over the Primary

side of the coil ,Now the circuit runs for hours with out loosing the 555 .It did bring some improvement,

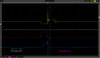

As you will see from the scope captures the Ignition is running fine (yellow Trace) Primary voltage is fine @385V however my issue still is a two part issue

(1) the current is much to high in the Primary (blue trace)as in this scope print 14A after

your help I realize what could be the problem the trigger pulse(to the FET) is at 50% which is around 3mSec that s much to long ,I will reduce that tomorrow and see what is the result on the current in the Primary.

(2) with this high current the 1N4500 runs to hot so I removed it which seems to cause me to have a large negative spike in the Primary voltage this is where my knowledge left me ,However if the pulse duty cycle brings the Current under control I will refit the 1N5400 and see if the negative spike on the primary is still there or not as shown below.

A correct operating circuit the Primary should not have the large negative going voltage

Thank you very much for your interest in my issue (problem) I will give it another go tomorrow with the info you helped me with

Regards