Hi,

so i'm making a project where a motor should drive a brush all the way up and down of the solar panel in order to clean it,

the rotation of the motor should be at 450RPM with 1nM torque,

i'm very confused concerning which type of motor should I choose (BLDC, Stepper, Brushed DC, servo …)

there are a lot of type of motors with different prices, so which one should you recommend to me?

Knowing that I want it to be as simple as possible, I would drive it through an arduino or an STM MCU.

I looked for BLDC 1Nm torque and they were rare and expensive at 1Nm, after looking little bit in the internet I noticed that stepper motor is used widely in CNC machine and other different applications and they were cheaper.

For example this one is a (1010 mNm = 1.01Nm) and it cost 55$ : https://www.digikey.com/product-det...l-gmbh/QSH5718-51-28-101/1460-1078-ND/4843429

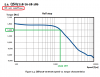

I want to know if this one can be driven at a speed of 450RPM ? and the maximum torque is constant at 450 RPM or it depend on the speed rotation ?

For BLDC I found this one : http://uk.rs-online.com/web/p/dc-motors/8928773/

it cost 146

and I found servo cheaper which has a maximum torque of 1.176Nm at 6 V : https://www.amainhobbies.com/align-ds610-digital-servo-agnhsd61001/p190915

which one should I choose ?

Thanks,

so i'm making a project where a motor should drive a brush all the way up and down of the solar panel in order to clean it,

the rotation of the motor should be at 450RPM with 1nM torque,

i'm very confused concerning which type of motor should I choose (BLDC, Stepper, Brushed DC, servo …)

there are a lot of type of motors with different prices, so which one should you recommend to me?

Knowing that I want it to be as simple as possible, I would drive it through an arduino or an STM MCU.

I looked for BLDC 1Nm torque and they were rare and expensive at 1Nm, after looking little bit in the internet I noticed that stepper motor is used widely in CNC machine and other different applications and they were cheaper.

For example this one is a (1010 mNm = 1.01Nm) and it cost 55$ : https://www.digikey.com/product-det...l-gmbh/QSH5718-51-28-101/1460-1078-ND/4843429

I want to know if this one can be driven at a speed of 450RPM ? and the maximum torque is constant at 450 RPM or it depend on the speed rotation ?

For BLDC I found this one : http://uk.rs-online.com/web/p/dc-motors/8928773/

it cost 146

and I found servo cheaper which has a maximum torque of 1.176Nm at 6 V : https://www.amainhobbies.com/align-ds610-digital-servo-agnhsd61001/p190915

which one should I choose ?

Thanks,