Hello,

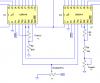

I have just joined the forum as I am looking for help in designing a circuit that I can use as a rudder indicator. Basically I am looking to have a row of red and green LED's light up sequentially when the rudder is moved in one direction or the other , typically 8 LED's in each direction. I would be looking to drive it from a wire wound pot connected to the rudder or any other method that would provide a reliable robust sender.

does anyone have any circuits out there or can point me in the right direction, I used to do hobby electronics in my younger days and can etch boards and have good soldering skills, Programmable chips are currently not something I have any experience with but open to learning new skills.

thanks for any assistance coming my way

Weegiemann

I have just joined the forum as I am looking for help in designing a circuit that I can use as a rudder indicator. Basically I am looking to have a row of red and green LED's light up sequentially when the rudder is moved in one direction or the other , typically 8 LED's in each direction. I would be looking to drive it from a wire wound pot connected to the rudder or any other method that would provide a reliable robust sender.

does anyone have any circuits out there or can point me in the right direction, I used to do hobby electronics in my younger days and can etch boards and have good soldering skills, Programmable chips are currently not something I have any experience with but open to learning new skills.

thanks for any assistance coming my way

Weegiemann