Hello, Adam

I did know that CMOS logic isn't appreciative of open inputs. And so it seems that analog inputs need some finite impedance too. I learned years ago that there is always some bias current (could be very small) associated with analog inputs, so some sort of resistive path must be provided for the bias current. Back in the day (before FETs) it was not uncommon to have 10 Meg-ohm "bias return current" resistors at the analog differential inputs if high input impedance was required. And then you still had to trim out the differential bias current, which caused temperature sensitivity. Later analog amps were laser trimmed at the factory to zero the differential bias current, but that was a long time ago. Things are "all better" now.

I loaded your latest code into MPLAB X and am now in the process of converting it to PIC10F206 code. The .inc file for your PIC10F320 has all the wrong labels for the '206 of course, so I changed it to include the header for the '206 instead of the '320, which made all the '320 labels invalid. Also had to change the assembler directive __CONFIG. I went through your code changing PORTA to GPIO and commenting out the things that don't work (aren't implemented) on the '206, but it still hasn't assembled without error yet. <sigh> Another rung on the learning-curve ladder to climb, but at least I am having fun.

If you disable MCLR the PIC will still reset if you cycle power.

I was so FOS on my earlier conjecture about using CALL $+1 to jump around the following SLEEP instruction. What I wanted to do was push the PSR on the stack without actually branching, but... there is no PUSH PSR instruction! No pushes or pops implemented on these PICs.

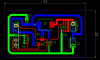

I did notice your PIC pin definitions didn't match up with the board I received from

@TenderTendon, so I corrected that too.

On your new board: there is no trace connecting the switch to pin 3 on the PIC.

More on this later...

Hop