I am very new to electronics so please forgive me if I use incorrect terminology. I really want to learn though.

I accidentally dialed one of the knobs too far and drew too much current while running a capacity test on a Lifepo4 prismatic 48V nominal battery bank that was fully charged at 58V.

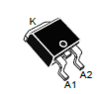

A spark came out of under the heat sink/fan and the fan stopped spinning.

I have removed the heat sink now to investigate if I can repair but I am not seeing any damage/burnt element(s) on the front and back side.

Does anyone have a suggestion on how to start to determine what blew?

I accidentally dialed one of the knobs too far and drew too much current while running a capacity test on a Lifepo4 prismatic 48V nominal battery bank that was fully charged at 58V.

A spark came out of under the heat sink/fan and the fan stopped spinning.

I have removed the heat sink now to investigate if I can repair but I am not seeing any damage/burnt element(s) on the front and back side.

Does anyone have a suggestion on how to start to determine what blew?