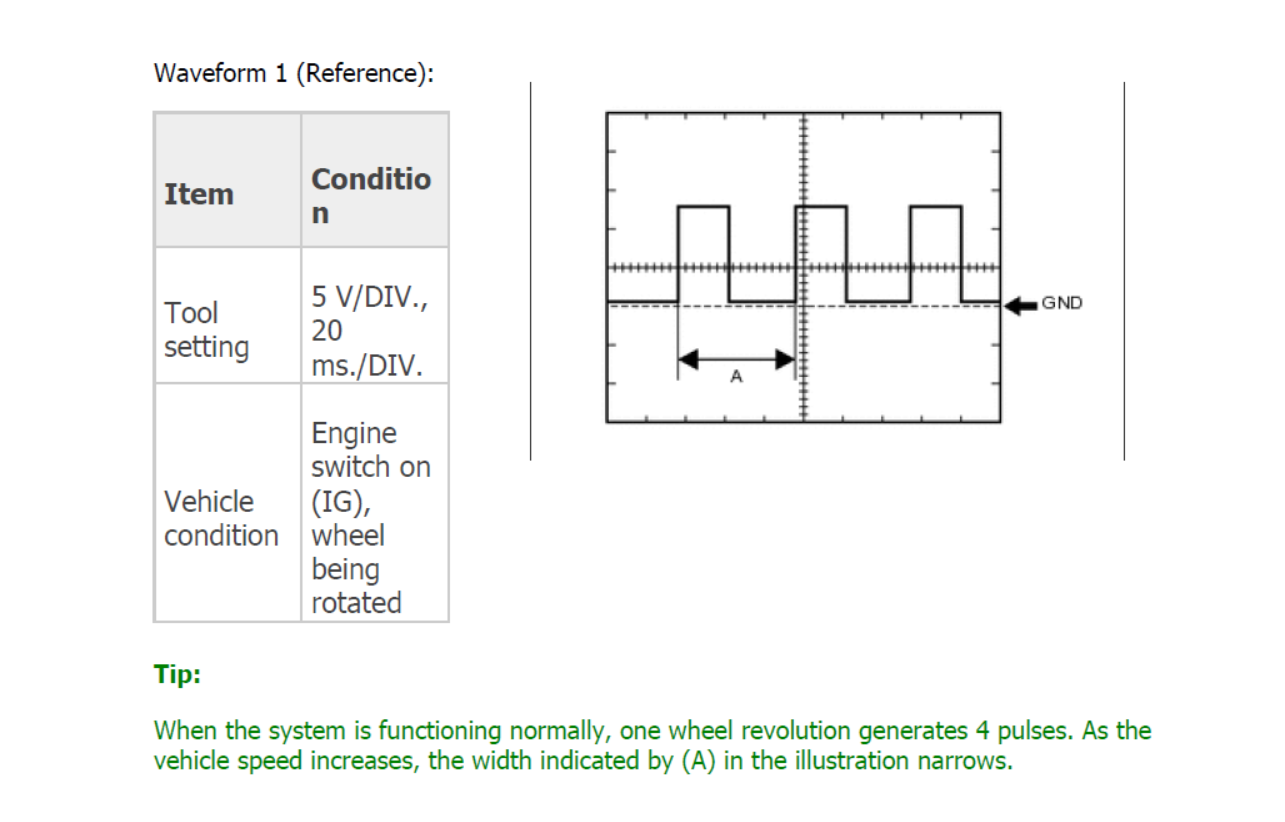

May I know the variation of pulse sequence width A?

Well, we don't know! In the sketch of the square wave it looks like the mark is slightly shorter than the space and as it's probably a mechanical magnetic pickup I guess that the M/S ratio will stay about the same even though the frequency will change, 4.2 Hz at 10mph and 42 Hz at 100mph!

A thought has struck me - is this wheel speed sensor a part of the ABS anti-skid system?