Hi John.

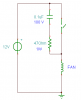

There are lots of different types of arc suppression and the one I chose is a cheap popular method. It stores some of the energy from the inductor in the capacitor, reducing the overall voltage spike. The energy stored in the capacitor is then is fed back to the load when the contacts closes again, hence the resistor which limits the current from the capacitor on closing of the contacts.

The diode you mentioned will work for D.C applications but has the drawback of reducing the time for the load to stop drawing current. Sometimes this can be a problem with very large solenoids like used for door magnets in which it may take a noticeable time for the magnet to release once the solenoid is de-energized. But for the fan it's not going to make much difference.

This is where the MOV comes in and basically shorts the coil out reducing the energy in the coil very quickly.

There are other methods using zener diode and a combination of capacitors, diodes and MOVs. The devices can get quite expensive when the voltages and current required to be handled go up. That's why the snubber is so popular. How ever for A.C applications the snubber can still supply current to the load in some cases this is undesirable, it all depends on the application.

Adam