I am building an intercooler for my home air compressor. This is basically a heat exchanger with a fan blowing over it, to help drop the temp of hot air as it exits the compressor pump head. I am also integrating a water trap, to pull the condensate out before the air continues on to the main tank of the compressor.

This unit needs to be turned "on" when the compressor is running, then turn "off" when the compressor stops. I could hardwire it into the control box of the compressor but I'd rather not do that, as the compressor is 220V and this intercooler will be 120V (plus I just don't want to mess around with the compressor wiring).

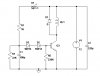

I was thinking that if there was some sort of simple sensor/switch I could adhere to the side of the compressor, to detect either the vibration of the compressor or the sound -- and then turn my intercooler on, and likewise in the absence of this condition turn the intercooler off -- this might work?

Needs to be simple, inexpensive and reliable. Do you know of anything out there already or is this easy enough to build?

This unit needs to be turned "on" when the compressor is running, then turn "off" when the compressor stops. I could hardwire it into the control box of the compressor but I'd rather not do that, as the compressor is 220V and this intercooler will be 120V (plus I just don't want to mess around with the compressor wiring).

I was thinking that if there was some sort of simple sensor/switch I could adhere to the side of the compressor, to detect either the vibration of the compressor or the sound -- and then turn my intercooler on, and likewise in the absence of this condition turn the intercooler off -- this might work?

Needs to be simple, inexpensive and reliable. Do you know of anything out there already or is this easy enough to build?