Hello EP Forums,

I found this hub while trying to fix my device. I'm looking to see if I can get some community advice so that I can keep from throwing another perfectly serviceable appliance in the trash. I've tinkered with electronics all my life, starting with my TV Antenna when I was a kid, eventually graduating to my computer. I've no education beyond HS physics though. Really the most I think I understand is simple circuits. Recently I replaced a bimetal thermostat on a space heater that suddenly stopped working. Successfully. Today however, I am out of my league. So, I am hoping to enlist your help. Here goes:

THE DEVICE/APPLIANCE

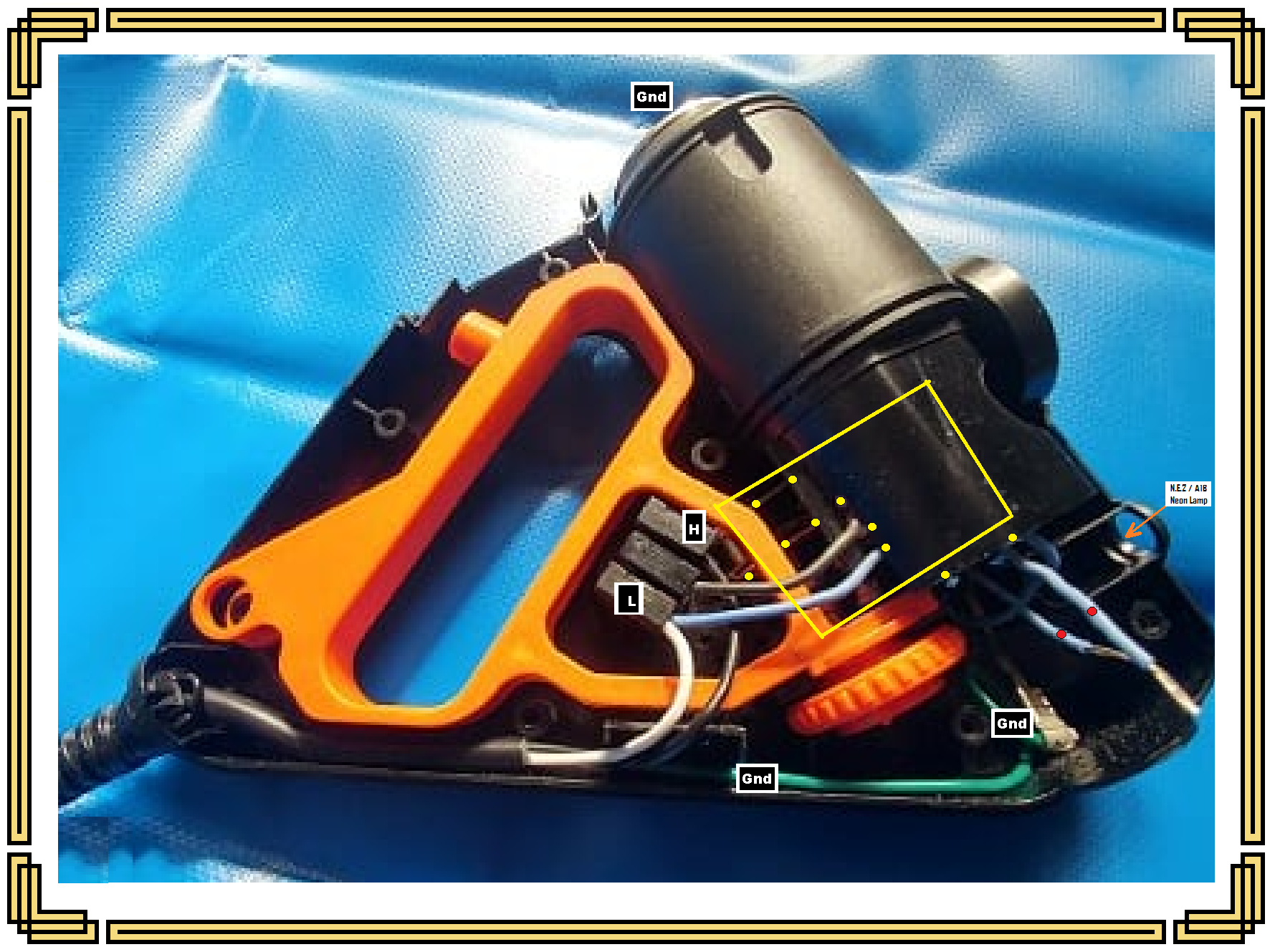

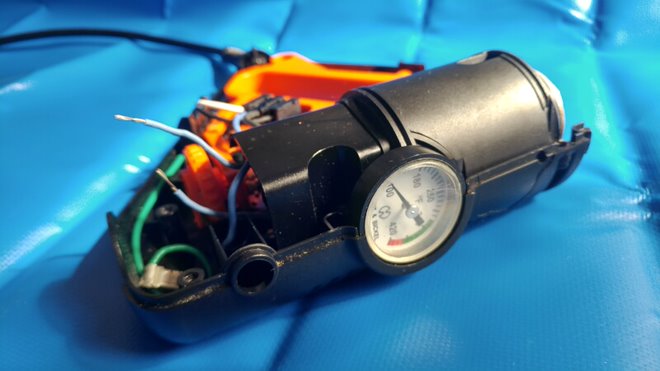

It’s a Storz and Bickel vaporizer. Basically, a heating element that allows a user to designate an upper temperature using a dial. While the device is heating, a little light bulb that turns on indicating the device is warming up. Once the device has reached the desired ‘heat level’ selected through the dial, the device has a thermostat that opens the circuit inside the device so that the heating element stops receiving current (stops heating up; an auto-off feature basically). When the circuit opens, the little bulb also turns off as well. If the user should choose to activate (close the circuit) the vaporizer again, one simply pulls a trigger on the device that trips some mechanism that closes the circuit to reactivate the heating element which then shuts off (again) at whatever upper temperature is selected. You get the idea. The device also has a switch to turn it on/off.

THE MISTAKE

I’ve owned this device for almost six years and it works great. I never had a reason to open it up. Until recently I spilled some juice on it, I opened it up to clean it, and once I put it back together it started acting funny: when I would turn the device on, it would heat up to the desired temperature no problem. Now however, once the temperature dropped and I pulled the trigger, the light would turn on for a moment, then off, then on, then off, like it was trying to heat up to the selected temp but had trouble. Initially I though perhaps I had accidentally moved a wire or something too close to the thermostat sensor and now the heating element was tripping up the thermostat. But then I realized it was just the light bulb had a faulty connection. Unfortunately, too much tinkering led to breaking the light bulb wiring.

THE PROBLEM

Thinking it was just a little light bulb with a simple circuit. I figured, oh well, I’ll just forgo the bulb and close the circuit by cutting out the bulb and splicing the wires leading in and out of the bulb. When I turned the device on for a half second, all the lights in my house went off for also a half second. Clearly not the correct course of action. So I took to more investigating.

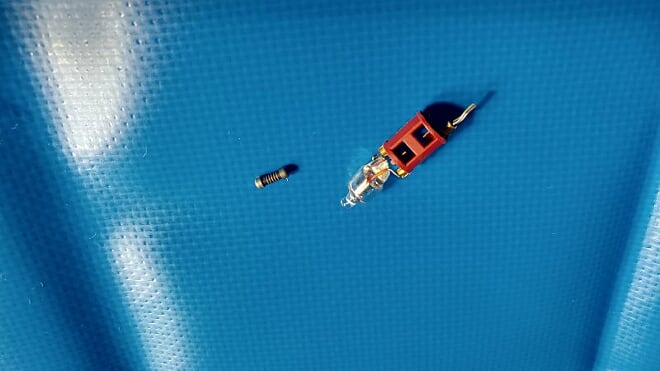

When I took apart the bulb, I noticed it is connected to a little chamber that has some tiny little battery looking thing (a resistor? diode?) that can be removed from this crimson colored housing. It has a grey/shite spiral marking. The bulb and crimson housing with tiny battery were all encased in another piece of white plastic that had some markings on it (???, 128V, 180°C, ???). I could not make the first and last parts out. The first part looks like the number 200 or it could be 20Ω but that’s pure conjecture, it really is too blurry to tell.

Anyway, that’s the issue. I’m hoping to get some input from anyone who can help me identify the parts that I need to replace so that I can fix this (what is this crimson housing called, is it sold at stores?). Or if these are custom parts, offer me a solution that I could rig so that the device works again (even without the lightbulb), safely. Ideally, I would like it to work as intended, with lightbulb and all. Check out the pictures below. If you have any suggestions or questions. I’ll check back to reply. Thanks strangers!

I found this hub while trying to fix my device. I'm looking to see if I can get some community advice so that I can keep from throwing another perfectly serviceable appliance in the trash. I've tinkered with electronics all my life, starting with my TV Antenna when I was a kid, eventually graduating to my computer. I've no education beyond HS physics though. Really the most I think I understand is simple circuits. Recently I replaced a bimetal thermostat on a space heater that suddenly stopped working. Successfully. Today however, I am out of my league. So, I am hoping to enlist your help. Here goes:

THE DEVICE/APPLIANCE

It’s a Storz and Bickel vaporizer. Basically, a heating element that allows a user to designate an upper temperature using a dial. While the device is heating, a little light bulb that turns on indicating the device is warming up. Once the device has reached the desired ‘heat level’ selected through the dial, the device has a thermostat that opens the circuit inside the device so that the heating element stops receiving current (stops heating up; an auto-off feature basically). When the circuit opens, the little bulb also turns off as well. If the user should choose to activate (close the circuit) the vaporizer again, one simply pulls a trigger on the device that trips some mechanism that closes the circuit to reactivate the heating element which then shuts off (again) at whatever upper temperature is selected. You get the idea. The device also has a switch to turn it on/off.

THE MISTAKE

I’ve owned this device for almost six years and it works great. I never had a reason to open it up. Until recently I spilled some juice on it, I opened it up to clean it, and once I put it back together it started acting funny: when I would turn the device on, it would heat up to the desired temperature no problem. Now however, once the temperature dropped and I pulled the trigger, the light would turn on for a moment, then off, then on, then off, like it was trying to heat up to the selected temp but had trouble. Initially I though perhaps I had accidentally moved a wire or something too close to the thermostat sensor and now the heating element was tripping up the thermostat. But then I realized it was just the light bulb had a faulty connection. Unfortunately, too much tinkering led to breaking the light bulb wiring.

THE PROBLEM

Thinking it was just a little light bulb with a simple circuit. I figured, oh well, I’ll just forgo the bulb and close the circuit by cutting out the bulb and splicing the wires leading in and out of the bulb. When I turned the device on for a half second, all the lights in my house went off for also a half second. Clearly not the correct course of action. So I took to more investigating.

When I took apart the bulb, I noticed it is connected to a little chamber that has some tiny little battery looking thing (a resistor? diode?) that can be removed from this crimson colored housing. It has a grey/shite spiral marking. The bulb and crimson housing with tiny battery were all encased in another piece of white plastic that had some markings on it (???, 128V, 180°C, ???). I could not make the first and last parts out. The first part looks like the number 200 or it could be 20Ω but that’s pure conjecture, it really is too blurry to tell.

Anyway, that’s the issue. I’m hoping to get some input from anyone who can help me identify the parts that I need to replace so that I can fix this (what is this crimson housing called, is it sold at stores?). Or if these are custom parts, offer me a solution that I could rig so that the device works again (even without the lightbulb), safely. Ideally, I would like it to work as intended, with lightbulb and all. Check out the pictures below. If you have any suggestions or questions. I’ll check back to reply. Thanks strangers!

Last edited: