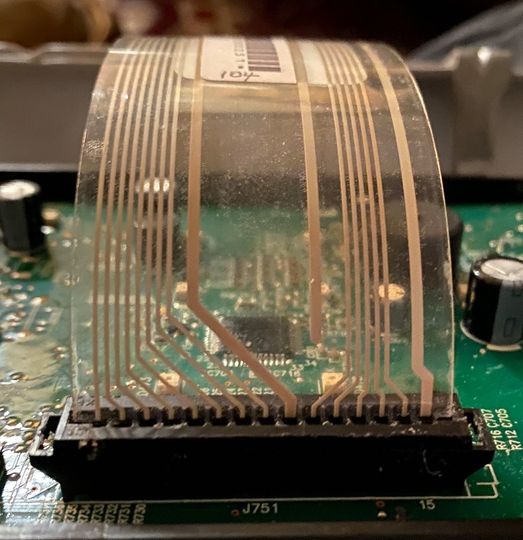

I have a touch button stove that transmits all of the buttons into one 15 pin cable. This plugs into a circuit board connector.

I was having issues with some buttons not working, some had to be touched just below where the button showed, and a few where I would push one button and get another response. I saw to clean the ribbon contacts, with alcohol, by removing from plug-in. This seemed to be working for awhile.

Another issue, when I tried to remove cable, it had locking tabs on each side of connector. One broke off and then the other. The stove is 11 years old, but these might have been brittle due to age.

It was suggested to push cable in, slide locking piece into position, and hot glue around edge. This also worked for awhile.

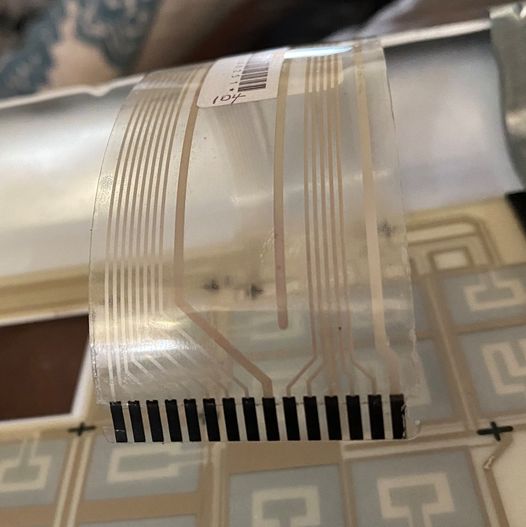

Now comes the part that is hard to explain. This ribbon is a clear plastic and the circuits can be seen. There seems to be a small gap of conductive material before another piece of plastic is wrapped from one to the other holding these in line. These uncovered areas to not even seem to touch the connectors. They seem to have something on the outside of the plastic and one of these has been almost completely rubbed off. I was wondering if these could be magnetic.

At this point I don't care what it takes to repair, even if that means soldering wires from ribbon connectors to socket one by one.

Can someone tell me how the conductive parts on ribbon could lay on top of plastic? And How I should go about fixing?

I was having issues with some buttons not working, some had to be touched just below where the button showed, and a few where I would push one button and get another response. I saw to clean the ribbon contacts, with alcohol, by removing from plug-in. This seemed to be working for awhile.

Another issue, when I tried to remove cable, it had locking tabs on each side of connector. One broke off and then the other. The stove is 11 years old, but these might have been brittle due to age.

It was suggested to push cable in, slide locking piece into position, and hot glue around edge. This also worked for awhile.

Now comes the part that is hard to explain. This ribbon is a clear plastic and the circuits can be seen. There seems to be a small gap of conductive material before another piece of plastic is wrapped from one to the other holding these in line. These uncovered areas to not even seem to touch the connectors. They seem to have something on the outside of the plastic and one of these has been almost completely rubbed off. I was wondering if these could be magnetic.

At this point I don't care what it takes to repair, even if that means soldering wires from ribbon connectors to socket one by one.

Can someone tell me how the conductive parts on ribbon could lay on top of plastic? And How I should go about fixing?