Sir coastman49 . . . . .

I wonder how many fuses were put in that unit until it finally melted down to this current state of disrepair ? . . . Are you fully familiar with that history ?.

I can see an

INITIAL core failure, of probably just 1 of 4 power transistors that are in the audio power output stages of that unit.

Irregardless of all of its protection / overload/ short / over voltage / over current circuitry.

Now, along comes a replacement fuse and a waiting for (11 teen [ Lebenteen] / 1000ths) of a second . .

.POW . . . there goes, potentially another / or more output transistors .

Then comes another fuse ( suspicioning . . . that last one was probably being a BAD fuse )

STA A A A A A N D

STA A A A A A N D . . . .

back here comes another fuse . . . . after all, there are 5 packaged in a box !

This time in the central core power unit . . . the D1201 Full Wave Bridge Rectifier block shorts down . . . another fuse gone . . . alas . . .no joy .

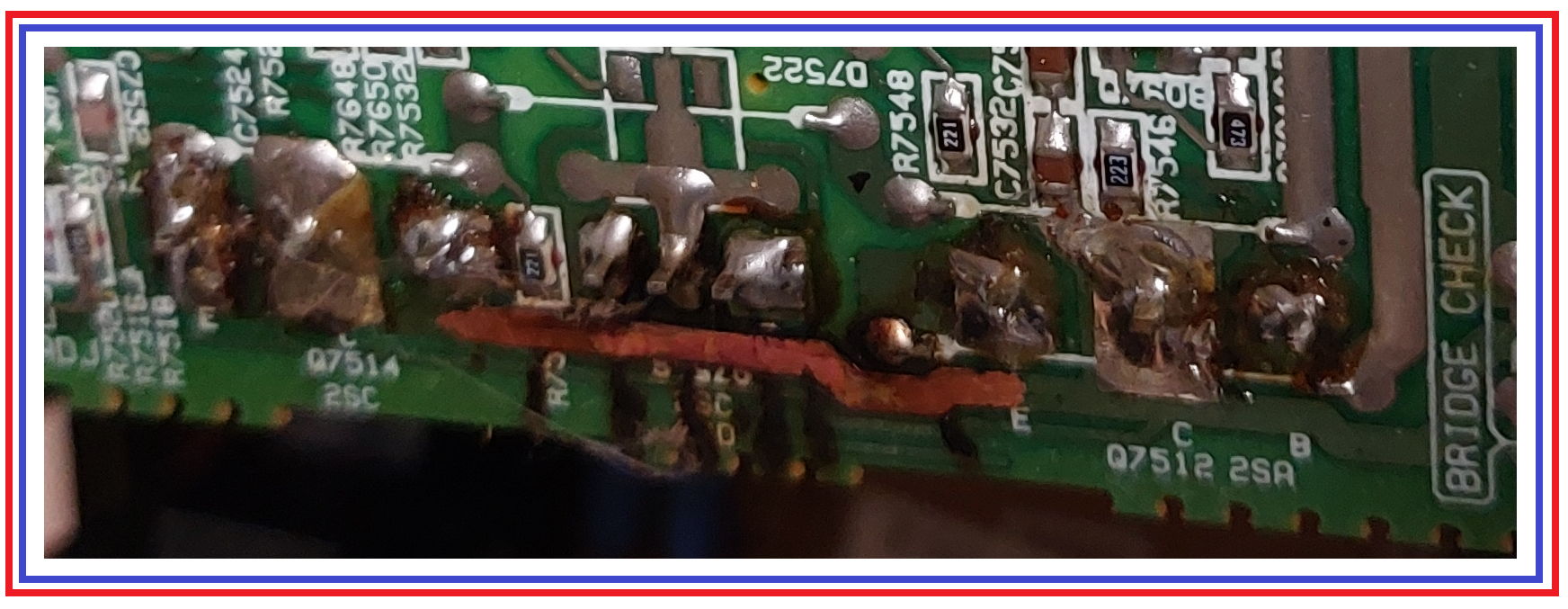

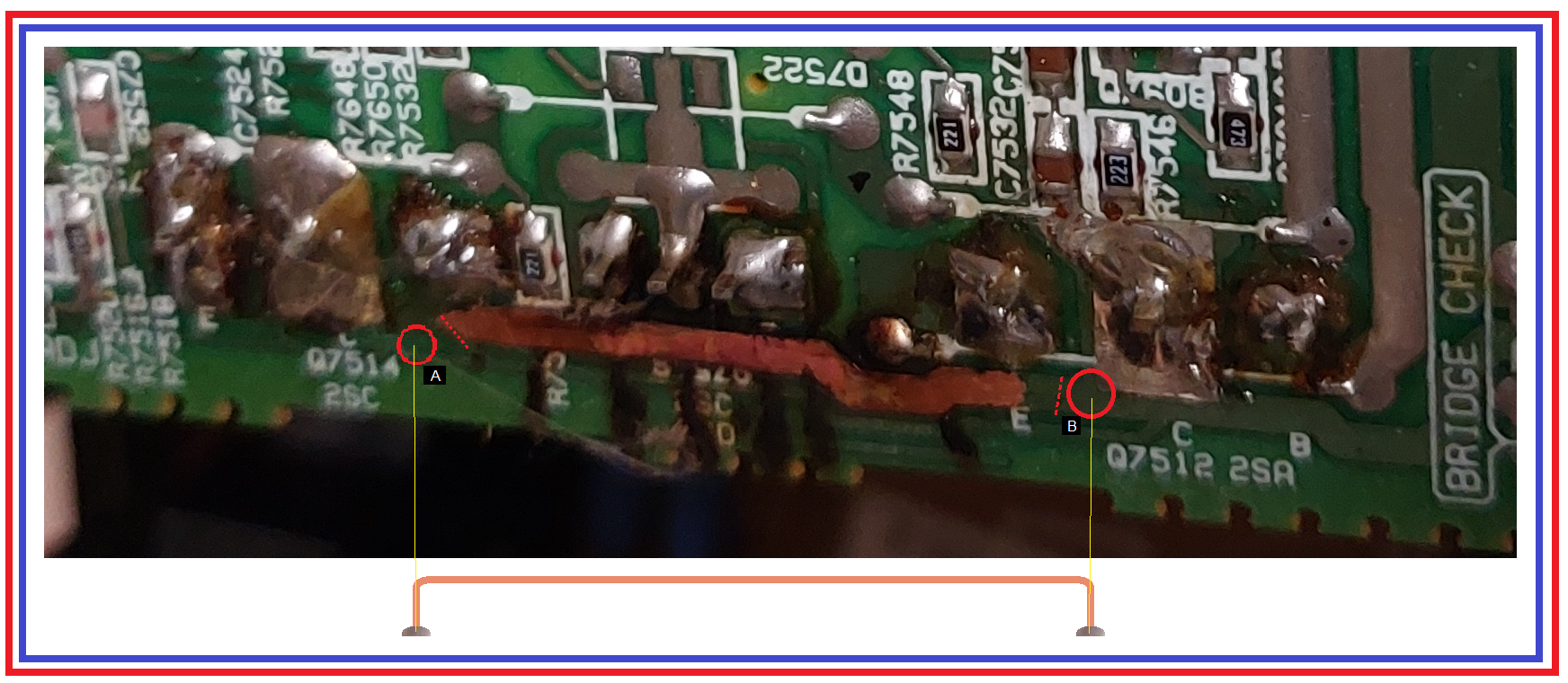

Well one to go . . . . . POWER UP . . . . . Hm m m m m m m m m . . . I wonder why that 1 1/2 inch length of circuit foil is glowing a dull cherry red ?

Am I . . .

PRECISELY . . . all up to date now ?

TRUISM . . . . .

The use of a 60-100 watt incandescent lamp, subbed in circuit for the fuse should be employed, initially, just after encountering a blown fuse.

NOT after sequentially blowing other fuses.

" Mouth to mouth doesn't revive a dead cadaver ".

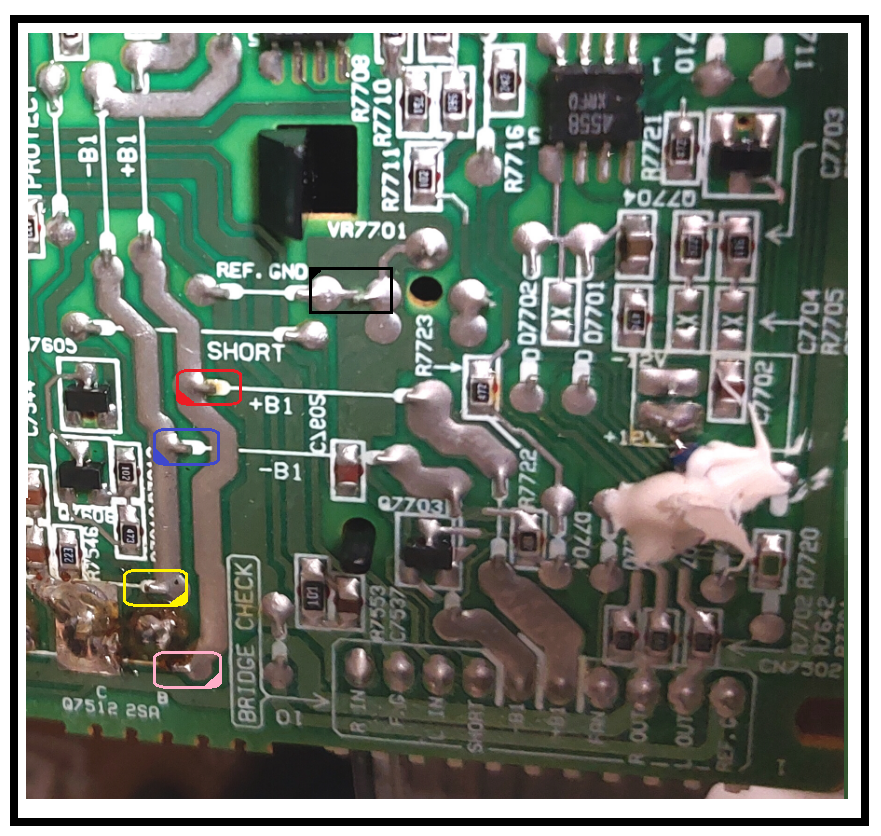

I think that you now have 1 or more shorted power transistors of its 4 and the

Full Wave Bridge Rectifier block is damaged . . in 1 x . . .2x or full 4 x of its sections..

AND . . at no extra charge . . .potentially the 2 . . .R1205 and R1206 resistors from the +- 50 VDC supplies to the main ground buss, are now being open circuit..

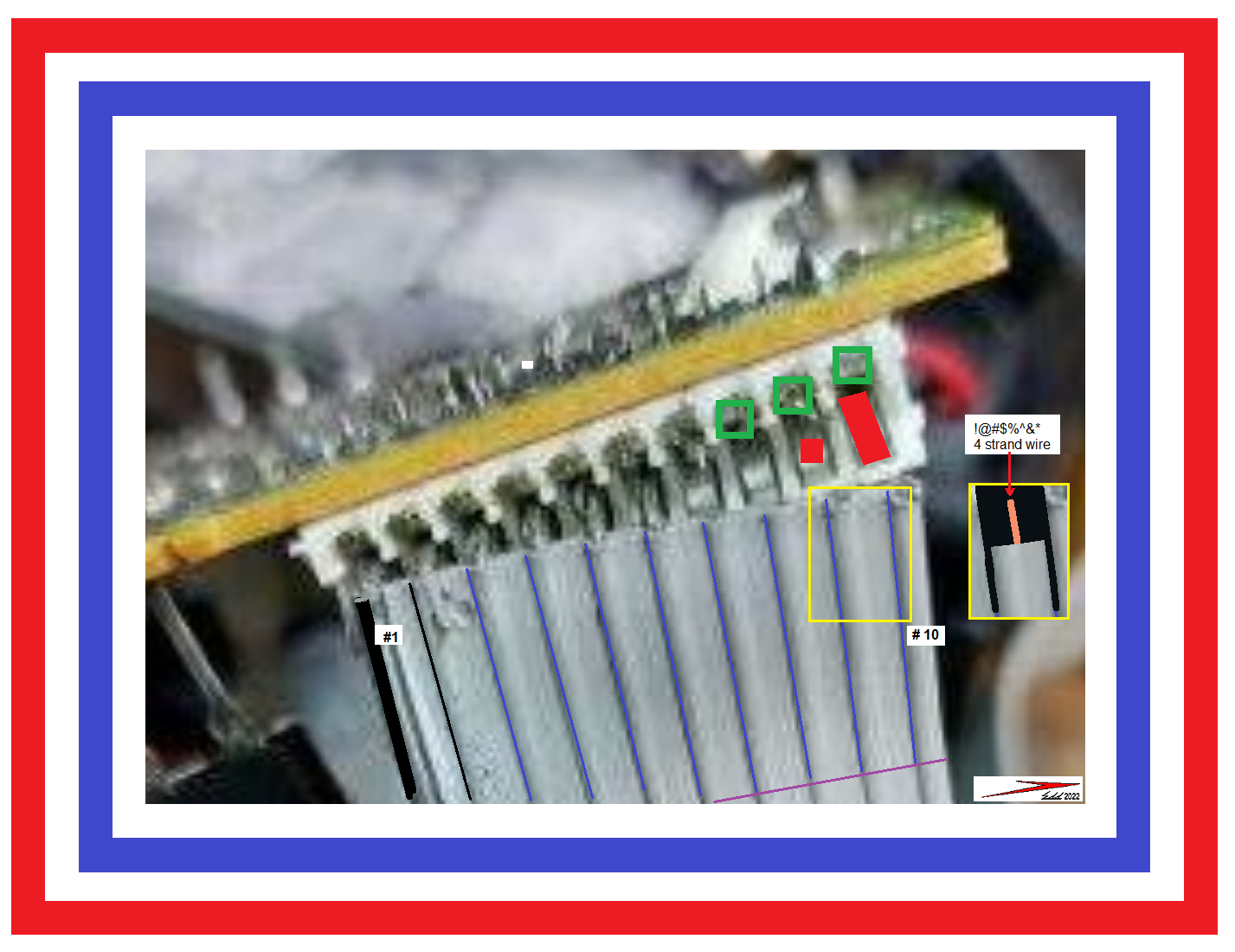

Considering that you will start with an unplugged , dead stone cold set from overnight inactivity, find the HUGE E-caps C1201 and C1202 and read the DC voltage across them. If any voltage is still present short it out. Then go to lowest ohms range and see if any short or low ohmmage is being read across their terminals.

Take your meter and put in low ohms range an short its probes together to see its meter reading .

Using the schematic below find the D1201 Rectifier block and pull it out of circuit and test its 4 diodes in low ohms resistance mode initially

Then go to diode test mode and see of being infinite in one directuion and reading the forward diode voltage ofg that diode in the other polarity in the testing each of its individual diode.

Expecting 1 or more shorted units.

Then go low ohms and see if see R1205 and R1206 might have opened up from overload.

D1206 . . . .it's a looka like 'a dis . . .

https://encrypted-tbn0.gstatic.com/...SuXURbVIvPrNDlj68Q_2etYpYD7319deiHW8&usqp=CAU

Lastly, you can test across the 4 POWER audio output transistors from their Collector to Emitters for any shorts or low ohms readings.

Likely SUSPECTING the 2 transistors near your former HOT foil area.

Waiting for results / or / any procedural assistance ? ?'s.

73's de Edd . . . . . . .

Be content with what you've got . . . . . but just first . . . . . initially be sure that you've got plenty.

.