I built a attic elevator using DC gear motors. It's a great unit with a platform that is the attic floor and can lift 500 pounds. It has turned the attic into a great storage area for everything and it's easy to ride up/down with stuff.

Okay, now the problem. The two motors are 24-volt with breaks, wheelchair motors. They were perfect because any type of failure and they would just stop. They're connected to a regulated power supply.

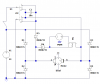

With a heavy load the power supply while going down is not able to keep the voltage at 12-volts and the motors speed up too much. I need some way to manage the voltage so that if the voltage exceeds 14-volts the current is somehow managed. I thought of connecting resistors but I have no idea if this would work and then how much to use since the problem gets worse as the weight going down pulls on the motors making them go faster.

Thanks.

Okay, now the problem. The two motors are 24-volt with breaks, wheelchair motors. They were perfect because any type of failure and they would just stop. They're connected to a regulated power supply.

With a heavy load the power supply while going down is not able to keep the voltage at 12-volts and the motors speed up too much. I need some way to manage the voltage so that if the voltage exceeds 14-volts the current is somehow managed. I thought of connecting resistors but I have no idea if this would work and then how much to use since the problem gets worse as the weight going down pulls on the motors making them go faster.

Thanks.