You can run the motor off the potentiometer, but it has to go before the base of the transistor where the switch is, then its not seeing the high current.

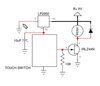

BS! The transistor is a MOSFET, acting as an on/off switch in series with the motor and the 9V battery. It does not have a "base," it has a "gate" controlled by TTL (Transistor Transistor Logic) logic levels from the touch switch. If you want to control the speed of the output shaft (this IS a gear-motor BTW), you can place a rheostat (a potentiometer wired as a variable resistor) in series with the 9V battery supply and the motor. Just disconnect the power from the battery to the motor and insert the potentiometer-wired-as-a-rheostat there.

From the size of the potentiometer you show in post #23, along with the size of your gear-motor and the 9V "smoke alarm" sized battery, I don't think you will have any problems with the "speed control" overheating. What you may have problems with is being able to afford to replace the battery when it expires... which will be in a matter of hours if run continuously. You may want to consider substituting a cheap "wall-wart" DC power supply for the battery. Or you can purchase a six-cell battery holder that allows you to insert six 1.5V AAA-, AA-, C-, or D-sized cells connected in series to create a 9V battery pack with greater energy capacity. And maybe use a cheap Asian pulse-width-modulated speed control module for better speed control. Not that you actually NEED these "bells and whistles" since you said in the beginning that the original circuit worked just fine for whatever purpose your friend had in mind.

As others have mentioned, a variable resistor inserted in series with the motor is a really poor way to control a permanent magnet DC motor, but it is (in effect)

exactly what you started with, before substituting the touch-switch for the original mechanical-switch. The only hiccup with doing this was the incompatibility of the touch-switch module with the 9V battery used to supply power to the motor. Plus, the touch-switch is not capable of providing power directly to the motor... hence the need for the MOSFET switch. And then you also needed a voltage regulator to "step down" the 9V battery voltage to the 5V maximum voltage that the touch switch accommodates.