Hello.

I will cut to the chase. I need to build a tig foot control for my migatronic ac/dc tig unit. I have contacted the manufacturers who have sent me the diagram for their foot control and would like someone to view the diagram and basicly verify what components I need to use where etc.

Would also like to have this listed somewhere as I know a few people have asked about this about this machine and normally end up paying vast amounts of money for a simple piece of kit.

Here's the info i got.

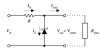

The foot pedal it's self has 2 plugs on it (as shown in pic) one plug is for turning the arc on and off (M2) and the variable part which is on M1. Also shown on the pedal is two potentiometers

Other info sent by manufactuer is regarding setup the plug for use when robotic welding, but give the info for what pins supplies or takes what

View attachment remote-connections.pdf

I hope you can see all the attachments and can help me verify components

I will cut to the chase. I need to build a tig foot control for my migatronic ac/dc tig unit. I have contacted the manufacturers who have sent me the diagram for their foot control and would like someone to view the diagram and basicly verify what components I need to use where etc.

Would also like to have this listed somewhere as I know a few people have asked about this about this machine and normally end up paying vast amounts of money for a simple piece of kit.

Here's the info i got.

The foot pedal it's self has 2 plugs on it (as shown in pic) one plug is for turning the arc on and off (M2) and the variable part which is on M1. Also shown on the pedal is two potentiometers

Other info sent by manufactuer is regarding setup the plug for use when robotic welding, but give the info for what pins supplies or takes what

View attachment remote-connections.pdf

I hope you can see all the attachments and can help me verify components