I blew out an old wax paper cap in my old bench grinder. Already have another more modern 4uf cap on the way.

Wondering how to find out if its the best value to use.

Its really old. Maybe it got home repaired with the wrong cap? Maybe they compromised on the original design? Maybe bigger caps where really expensive or unreliable at the time? Maybe its small to keep the power bill down? What about Power Factor Correction? I'm interested in more output power over less consumption, as I hardly use it. Although more out for less in is always nice.

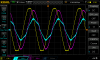

My current plan is to stick a low ohm (1 or less) high wattage resistor (possibly a nail or something) between the grinder and neutral then put it on the oscope.

One channel watching current lag via the shunt and the another channel on the live input, maybe a third channel on the start/direction coil.

I have a stack of suitable caps to play with. Microwave Capacitors, a couple of motor start/run caps from 6uf to 25uf.

I should be able to have a bit of a play around to reinforce book knowledge. Hopefully find the ideal cap value without frying the windings. Test runs will be short and there will be lots of cool down time while I change caps around anyway.

Obviously the wiring is looking a bit sad, I might as well replace all that while its half naked.

If I'm going to go that far I may as well learn how to find the right cap on paper too.

I imagine I could measure the inductance and resistance of the coils and do some math the find the right value.

Google wasn't very helpful here. Can someone point me to the theory? (this bits bold and underlined as its the main question I came here with)

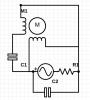

Also if I find a power factor (worth bothering with), would a cap in parallel with the motor be the best way to correct it? Seems like that would waste some power? But if I go in series it seems I'm gong to need a massive cap to pass enough current? And whats that going to do to the start/direction coil phase?? Same if I PFC the run coil alone, Wont it change the phase relationship with the start/direction coil??

Also any other suggestions for making my grinder better/safer or improving my learning experience would be greatly appreciated.

Wondering how to find out if its the best value to use.

Its really old. Maybe it got home repaired with the wrong cap? Maybe they compromised on the original design? Maybe bigger caps where really expensive or unreliable at the time? Maybe its small to keep the power bill down? What about Power Factor Correction? I'm interested in more output power over less consumption, as I hardly use it. Although more out for less in is always nice.

My current plan is to stick a low ohm (1 or less) high wattage resistor (possibly a nail or something) between the grinder and neutral then put it on the oscope.

One channel watching current lag via the shunt and the another channel on the live input, maybe a third channel on the start/direction coil.

I have a stack of suitable caps to play with. Microwave Capacitors, a couple of motor start/run caps from 6uf to 25uf.

I should be able to have a bit of a play around to reinforce book knowledge. Hopefully find the ideal cap value without frying the windings. Test runs will be short and there will be lots of cool down time while I change caps around anyway.

Obviously the wiring is looking a bit sad, I might as well replace all that while its half naked.

If I'm going to go that far I may as well learn how to find the right cap on paper too.

I imagine I could measure the inductance and resistance of the coils and do some math the find the right value.

Google wasn't very helpful here. Can someone point me to the theory? (this bits bold and underlined as its the main question I came here with)

Also if I find a power factor (worth bothering with), would a cap in parallel with the motor be the best way to correct it? Seems like that would waste some power? But if I go in series it seems I'm gong to need a massive cap to pass enough current? And whats that going to do to the start/direction coil phase?? Same if I PFC the run coil alone, Wont it change the phase relationship with the start/direction coil??

Also any other suggestions for making my grinder better/safer or improving my learning experience would be greatly appreciated.