I would like to request a couple of changes to the design before this gets wrapped up. These changes will probably occur anyway for different reasons, but here are mine:

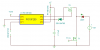

1) The Schottkey diode absolutely needs to be substituted. The one I purchased (

http://www.digikey.com/product-detail/en/0/LSM115JE3/TR13CT-ND) is huge and won't fit on a 14mm round board. Also, it is taller than the switch and will interfere with it it's actuation.

2) I know we have all discussed changing to a larger capacitor for electrical reasons, but I would like to go larger for mechanical reasons also. The one I have (

http://www.digikey.com/product-detail/en/0/445-1604-1-ND) is so tiny that I have trouble working with it, even under magnification. I would welcome a larger footprint.

That's it. I know you all started to cringe when you read the first sentence. Sorry about that.

I know there's a few reasons that my circuit is not behaving the same as Adam's. One certain possibility is that I screwed up the asm file while editing it. Another thing I just thought of is the posiblility of the files ending up slightly altered after the zip/unzip process. If you think this could happen, we could exchange raw, uncompressed files via email instead...