I'm trying to interface an Allegro A1160 half-effect sensor to a TI MSP430 CPU.

The A1160 is a 5V device whilst the MSP430 operates from a 1.8V to 3.6V supply. The MSP430 has onboard ADC, but the analog input pins have an absolute max rating of VCC + 0.3V.

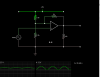

I have both 3.3V and 5V regulators on my PCB design and I'm assuming that I'll need some opamps or something to interface between the MSP430 CPU and the A1160 sensor.

I'm still fairly new to electronics design and I'm looking for advice as to a good way to interface these two devices.

The A1160 is a 5V device whilst the MSP430 operates from a 1.8V to 3.6V supply. The MSP430 has onboard ADC, but the analog input pins have an absolute max rating of VCC + 0.3V.

I have both 3.3V and 5V regulators on my PCB design and I'm assuming that I'll need some opamps or something to interface between the MSP430 CPU and the A1160 sensor.

I'm still fairly new to electronics design and I'm looking for advice as to a good way to interface these two devices.