Greetings! I am new to the forums and hopeful that someone can assist me in repairing a couple of old VCR's.

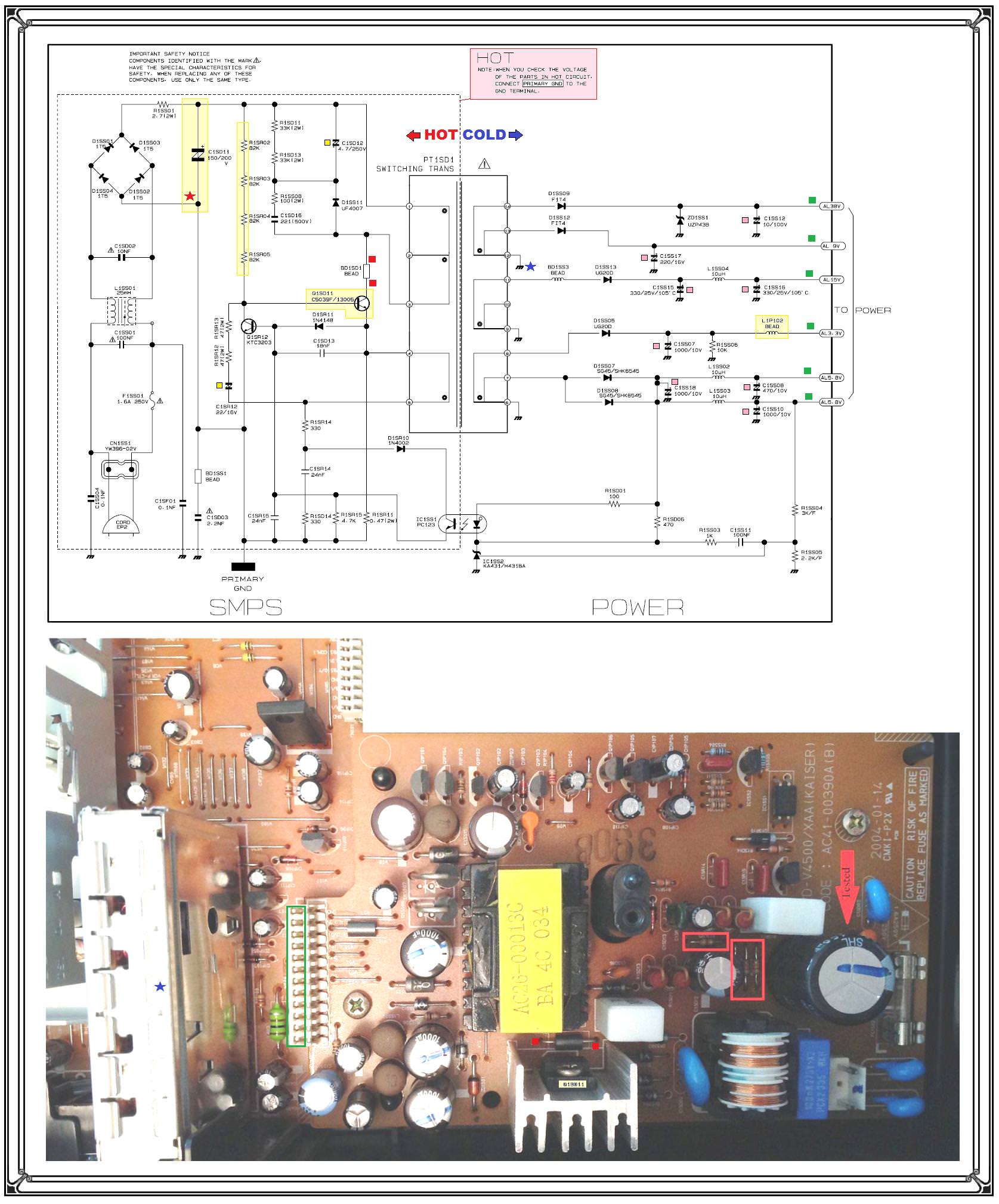

The first VHS/VCR is a Samsung DVD-V4600 unit I purchased at a thrift store. I happily brought it home and plugged it in to find that it had no power whatsoever. No lights, no blips, nadda. Dead. Now I'm not so happy. I unplugged the unit, took off the lid and did a visual inspection. The unit, to my surprise, looks pretty clean. I examined the components and I do not see any visual indicators as to the issue. No bulging or leaky capacitors, no burn marks, etc. The fuse is not blown. I plugged the unit in and noticed a buzzing/humming noise coming from the power supply area. (Naturally I googled "buzzing smps" thinking this would lead me in the right direction. Sadly, unlike on television, google was utterly useless). Determined not to give up I spent hours googling and reading about switch mode power supplies. I bought a capacitance meter and discharged the big main capacitor and measured it. It seems fine. I then tested what I believe to be the "startup" resistors. I removed one leg from the board first. These measured fine also. Next I considered testing the mosfet but the transformer is blocking my screwdriver making it difficult to remove. I'm hoping someone can give me advice on what to try next... Photos of the power supply are below (I've indicated the capacitor and resistors I tested in the second photo). Any questions please let me know and thank you in advance for any help you can provide!

Summary:

No visual signs of defects (bulging, leaking capacitors, etc.)

Buzzing noise coming from power supply

Tested large capacitor and startup resistors = ok

Fuse is not blown

I was able to find the service manual online. Here

The first VHS/VCR is a Samsung DVD-V4600 unit I purchased at a thrift store. I happily brought it home and plugged it in to find that it had no power whatsoever. No lights, no blips, nadda. Dead. Now I'm not so happy. I unplugged the unit, took off the lid and did a visual inspection. The unit, to my surprise, looks pretty clean. I examined the components and I do not see any visual indicators as to the issue. No bulging or leaky capacitors, no burn marks, etc. The fuse is not blown. I plugged the unit in and noticed a buzzing/humming noise coming from the power supply area. (Naturally I googled "buzzing smps" thinking this would lead me in the right direction. Sadly, unlike on television, google was utterly useless). Determined not to give up I spent hours googling and reading about switch mode power supplies. I bought a capacitance meter and discharged the big main capacitor and measured it. It seems fine. I then tested what I believe to be the "startup" resistors. I removed one leg from the board first. These measured fine also. Next I considered testing the mosfet but the transformer is blocking my screwdriver making it difficult to remove. I'm hoping someone can give me advice on what to try next... Photos of the power supply are below (I've indicated the capacitor and resistors I tested in the second photo). Any questions please let me know and thank you in advance for any help you can provide!

Summary:

No visual signs of defects (bulging, leaking capacitors, etc.)

Buzzing noise coming from power supply

Tested large capacitor and startup resistors = ok

Fuse is not blown

I was able to find the service manual online. Here