Hey guys,

I'm very new to understanding electronics, and I don't speak equation, but I'm hoping I can get some help with my project. I’m building a power supply to replace the 18Volt batteries on my Ryobi Power Tools; I’ve successfully completed it, but have ended up creating a 29V power supply, instead of 18-20V. I need to know what resistors I need to take my rectified voltage down to 20VDC so I can smooth it thru the capacitor for final use. I understand that I will need to wire them in series, but don’t know how to calculate the sizes I need that will maintain 20amps without burning up. Total voltage drop should be 8 or 9V. Equations welcome if each component is explained..

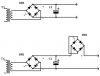

BACKGROUND INFO: I bought a 120-to-20VAC 400VA Toroidal transformer (2x coils at 20V 10A each), and two bridge rectifiers (50V 20A rated), as well as a 10,000µF AlumElec capacitor (20V rated). My original assumption from everything I found online was that this would give me a smoothed 18.x Volts DC around 20Amps, after full-wave rectification and smoothing. Upon completion, I got 18.x VDC after rectification, but then discovered that I get 29.x V DC after connecting capacitor. A few thousand equation-riddles search results later, one kind person explained that the 18.x VDC I was reading was the RMS voltage, but that the capacitor will keep my final voltage near the Peak voltage of the rectified DC, something more like 29V. That finally makes sense, however, when I plug my power tools in, the motors run way higher than they should, and my 20V-rated capacitor would likely explode under sustained load. I need to know what size of resistors I can wire in series to drop my 29Volts down to 20V without losing (much) amperage. After bringing the voltage down to 20, I will pass it by my capacitor in parallel, and it’s ready for use. I am also aware that under full load, my final RMS voltage will drop down around 17V, but the tools are 18V, so this is acceptable.

Any help is appreciated, but I ask that if you starting speaking equation, you explain each component of the formula so I can understand the ‘why’ behind it. Thanks!

I'm very new to understanding electronics, and I don't speak equation, but I'm hoping I can get some help with my project. I’m building a power supply to replace the 18Volt batteries on my Ryobi Power Tools; I’ve successfully completed it, but have ended up creating a 29V power supply, instead of 18-20V. I need to know what resistors I need to take my rectified voltage down to 20VDC so I can smooth it thru the capacitor for final use. I understand that I will need to wire them in series, but don’t know how to calculate the sizes I need that will maintain 20amps without burning up. Total voltage drop should be 8 or 9V. Equations welcome if each component is explained..

BACKGROUND INFO: I bought a 120-to-20VAC 400VA Toroidal transformer (2x coils at 20V 10A each), and two bridge rectifiers (50V 20A rated), as well as a 10,000µF AlumElec capacitor (20V rated). My original assumption from everything I found online was that this would give me a smoothed 18.x Volts DC around 20Amps, after full-wave rectification and smoothing. Upon completion, I got 18.x VDC after rectification, but then discovered that I get 29.x V DC after connecting capacitor. A few thousand equation-riddles search results later, one kind person explained that the 18.x VDC I was reading was the RMS voltage, but that the capacitor will keep my final voltage near the Peak voltage of the rectified DC, something more like 29V. That finally makes sense, however, when I plug my power tools in, the motors run way higher than they should, and my 20V-rated capacitor would likely explode under sustained load. I need to know what size of resistors I can wire in series to drop my 29Volts down to 20V without losing (much) amperage. After bringing the voltage down to 20, I will pass it by my capacitor in parallel, and it’s ready for use. I am also aware that under full load, my final RMS voltage will drop down around 17V, but the tools are 18V, so this is acceptable.

Any help is appreciated, but I ask that if you starting speaking equation, you explain each component of the formula so I can understand the ‘why’ behind it. Thanks!