Hello everyone! I'm planning a project which aims to regulate an output voltage from 0 to +5V DC by using a force sensitive resistor. This is for a musical implementation: I own a guitar pedal which accepts 0 to +5V voltage to control certain parameters. I want to push on the sensor with my finger to control these parameters.

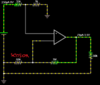

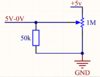

Originally I had planned a circuit using an op-amp (schematic attached; the sensor is represented by the 68k resistor because it starts at several million ohms with zero pressure and gets down to ~68k ohms with maximum pressure). with a 1meg potentiometer in the feedback loop to fine-tune the response. The 50k load represents the input of the guitar pedal (this value sourced from the owner's manual). I planned the op-amp circuit because, according to datasheets, this would result in the most linear response.

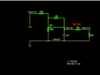

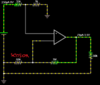

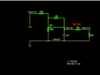

When attempting to breadboard the circuit, the op-amp was damaged and I didn't have a replacement. I didn't want to order parts just yet so I tested a 9V wall wart running straight through the sensor, and was surprised to find the response was quite linear. (Perhaps this can be explained by the non-linear nature of the FSR being cancelled out by the non-linear nature of increasing pressure with your fingers?). So I tried coming up with a simpler circuit (schematic attached).

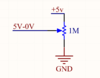

In this schematic, the 100k pot controls the incoming voltage to fine-tune the response. The 6.8k resistor in series is to lower the current running through the pot when it is at minimum resistance to avoid damaging the pot (I have since lowered this value to 2k). The 50k resistor in parallel has a similar effect of allowing the current to flow elsewhere besides through the pot, and it also smoothed out the taper of the output voltage. Again, the 50k load represents the guitar pedal. (Ignore the capacitor, I think it's unnecessary.)

Do you guys think the second circuit will suffice? One issue that I'm aware of is that the load will have a significant effect on the output. However, because the load will always be the same (i.e. I'm always going to use the same guitar pedal), does this matter? I thought it was weird when I simulated the circuit online that there was zero current flowing, but an email from the manufacturer: "the input is 0-5V, current won’t matter because there’s a >50k input resistor and the current is self regulating and protected." He also told me the pedal has overvoltage protection, which alleviates another potential concern.

Another person helping me warned that the FSR might be damaged by the high voltage. I'm unable to find any relevant information in the FSR's datasheet. That being said, when breadboarding I was running 9v (and later 12v) straight through the sensor, with no damage. But perhaps extended use will damage it?

Originally I had planned a circuit using an op-amp (schematic attached; the sensor is represented by the 68k resistor because it starts at several million ohms with zero pressure and gets down to ~68k ohms with maximum pressure). with a 1meg potentiometer in the feedback loop to fine-tune the response. The 50k load represents the input of the guitar pedal (this value sourced from the owner's manual). I planned the op-amp circuit because, according to datasheets, this would result in the most linear response.

When attempting to breadboard the circuit, the op-amp was damaged and I didn't have a replacement. I didn't want to order parts just yet so I tested a 9V wall wart running straight through the sensor, and was surprised to find the response was quite linear. (Perhaps this can be explained by the non-linear nature of the FSR being cancelled out by the non-linear nature of increasing pressure with your fingers?). So I tried coming up with a simpler circuit (schematic attached).

In this schematic, the 100k pot controls the incoming voltage to fine-tune the response. The 6.8k resistor in series is to lower the current running through the pot when it is at minimum resistance to avoid damaging the pot (I have since lowered this value to 2k). The 50k resistor in parallel has a similar effect of allowing the current to flow elsewhere besides through the pot, and it also smoothed out the taper of the output voltage. Again, the 50k load represents the guitar pedal. (Ignore the capacitor, I think it's unnecessary.)

Do you guys think the second circuit will suffice? One issue that I'm aware of is that the load will have a significant effect on the output. However, because the load will always be the same (i.e. I'm always going to use the same guitar pedal), does this matter? I thought it was weird when I simulated the circuit online that there was zero current flowing, but an email from the manufacturer: "the input is 0-5V, current won’t matter because there’s a >50k input resistor and the current is self regulating and protected." He also told me the pedal has overvoltage protection, which alleviates another potential concern.

Another person helping me warned that the FSR might be damaged by the high voltage. I'm unable to find any relevant information in the FSR's datasheet. That being said, when breadboarding I was running 9v (and later 12v) straight through the sensor, with no damage. But perhaps extended use will damage it?