If one of the tracks from the "contacts" (output) of the SSR to the solenoid went up in smoke, that's because too much current was flowing through it. That means that either the current was higher than it should have been, or the track was thinner than it should have been.

Solenoids are normally able to be energised continuously. Their DC resistance limits the amount of current they draw while activated (assuming you are applying the right voltage across them). So if there was no short, there's no reason why a very high current would have been flowing.

As Steve asked, what is the DC resistance (or the operating current) of the solenoid, and how wide was the track that vaporised?

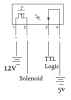

Here's a schematic for how you should have the CPC1708 SSR connected. This demonstrates several things that I've mentioned in earlier posts on this thread.

Most logic-level outputs cannot provide 15 mA to drive the LED in the CPC1708 so you should use a transistor buffer, Q1. The type is not critical but I've suggested a 2N3904 which is widely available. When the controller drives the input (marked CONTROL) high, current through R1 forward-biases Q1 and it conducts current in its collector circuit. This current flows from the +5V rail, through the LED inside the CPC1708, through R3, and through Q1.

R3 limits this current to around 16~17 mA. You could actually increase R3 from 220Ω as marked, to 270Ω or even 330Ω and still be within the guaranteed specifications for the CPC1708, while saving a bit of current.

When the LED in the CPC1708 illuminates, the MOSFET inside the CPC1708 conducts. This applies the 12V supply (which I've shown as an isolated battery) across the solenoid. The solenoid's DC resistance will limit this current to the value specified in the data sheet for the solenoid.

When the CONTROL signal goes low, Q1 turns OFF, the LED stops emitting infra-red light, the MOSFET turns OFF, and the current in the solenoid starts to collapse. This causes the solenoid to generate a reverse voltage called "back EMF" which is clamped by the combination of the 1N400x diode and the zener. The presence of the zener allows the solenoid current to collapse more quickly than it would if just the diode was present, because the back EMF voltage is clamped to a voltage much higher than zero.

Since the MOSFET in the CPC1708 is rated for 60V maximum and there is already 12V from the battery, the back EMF voltage must be limited to 48V by the zener diode; I would use a 39V or 33V zener to be safe. The zener will actually dissipate nearly all of the energy from the solenoid and may need to be rated at 3W, 5W, or even more.

I don't know how to calculate the required power rating; it depends on the inductance of the solenoid (including the motional inductance) and the surge rating of the zener. Perhaps you can post a link to the data sheet for the solenoid and Steve may be able to provide guidance on the zener's power rating.

The 5v and control logic TTL line is from development board, 12v is from a battery

The 5v and control logic TTL line is from development board, 12v is from a battery