Hi guys and gals!

I hope you guys can help me, im looking for a way to disable a secondary power source when the first one is re-connected.

I have a kids bike trailer/stroller that i want to put some lights on, mainly rear turn indicator and position (red) light for when its used with my bike, but also front (white) lights for night strolls.

Since my bike is having its electronics overhauled i figured i just throw in yet another problem in the mix..

Now, my bike has a battery, that will provide power to the whole system and i want to use it to power the trailer lights aswell, so i know that my whole vehicle is lit up when in traffic.

Currently i have 3x battery packs on my bike and its not a rare occation that i notice that one of the packs is dead, therefore i want a single pack and a single problem to remember about.

But i also would like to use a secondary (smaller) battery onboard the trailer, so i can just turn on the front lights and bypass all the other electronics (Pin extender, FET transistors and so on) when the trailer is used for walking.

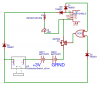

I imagine two circuits, the bike circuitry on the left, and my stand-alone-light circuit on the right, containing a switch, battery and a resistor for that imaginary front headlight in the middle.

As one of the circuit is turned off, i can turn the light on with any one circuit.

But my headache starts when i "forget" to disable the secondary battery with the stand-alone-light-switch, i figure i will be feeding that front light double the juice, probably burning it up in a flash.

So i need a way to disable the secondary "system" in a automatic way, as soon as i connect the power from the bike.

Ive been trying to use transistors, trying to figure out how to "invert" their behaviour, keep open when no signal and use the voltage input (from the bike) as a off-trigger.

But im simply not smart enough (or educated enough) to solve this riddle on my own..

Someone suggested a relay but im not too sure.. Appearantly it requires a certain type of relay and im having dificoulties finding one matching the tipsters vauge descriptions.. is that really the best option here?

I hope you guys can help me, im looking for a way to disable a secondary power source when the first one is re-connected.

I have a kids bike trailer/stroller that i want to put some lights on, mainly rear turn indicator and position (red) light for when its used with my bike, but also front (white) lights for night strolls.

Since my bike is having its electronics overhauled i figured i just throw in yet another problem in the mix..

Now, my bike has a battery, that will provide power to the whole system and i want to use it to power the trailer lights aswell, so i know that my whole vehicle is lit up when in traffic.

Currently i have 3x battery packs on my bike and its not a rare occation that i notice that one of the packs is dead, therefore i want a single pack and a single problem to remember about.

But i also would like to use a secondary (smaller) battery onboard the trailer, so i can just turn on the front lights and bypass all the other electronics (Pin extender, FET transistors and so on) when the trailer is used for walking.

I imagine two circuits, the bike circuitry on the left, and my stand-alone-light circuit on the right, containing a switch, battery and a resistor for that imaginary front headlight in the middle.

As one of the circuit is turned off, i can turn the light on with any one circuit.

But my headache starts when i "forget" to disable the secondary battery with the stand-alone-light-switch, i figure i will be feeding that front light double the juice, probably burning it up in a flash.

So i need a way to disable the secondary "system" in a automatic way, as soon as i connect the power from the bike.

Ive been trying to use transistors, trying to figure out how to "invert" their behaviour, keep open when no signal and use the voltage input (from the bike) as a off-trigger.

But im simply not smart enough (or educated enough) to solve this riddle on my own..

Someone suggested a relay but im not too sure.. Appearantly it requires a certain type of relay and im having dificoulties finding one matching the tipsters vauge descriptions.. is that really the best option here?