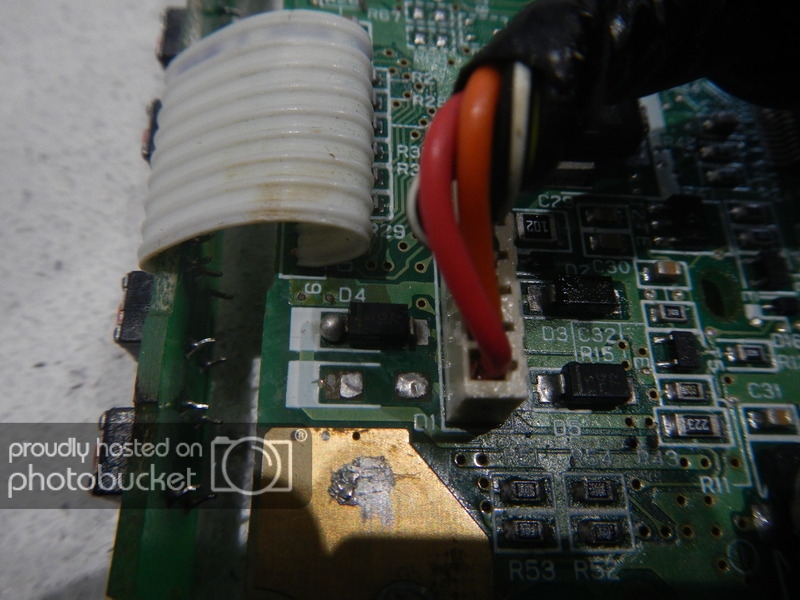

im trying to repair the board for a display unit on my dirt bike.

two of the diodes suffered some corrosion around the legs which caused the display to fail.

Ive sourced what i think should be suitable replacements for soldering back on to the board.

Before i do that i wanted to check the condition of the solder pads.

From the photos can you guys tell if the pads shown in the pic ( where one of the diodes has been removed) are in usable condition?

Ive given them a clean up with electrical contact cleaner but they dont look great. Im not sure if they are badly corroded or just need more cleaning!

is there any way i can check them with a multimeter before starting any soldering?

Im not an expert on this so thought i see if i might need to do anything else before attempting to solder the new items

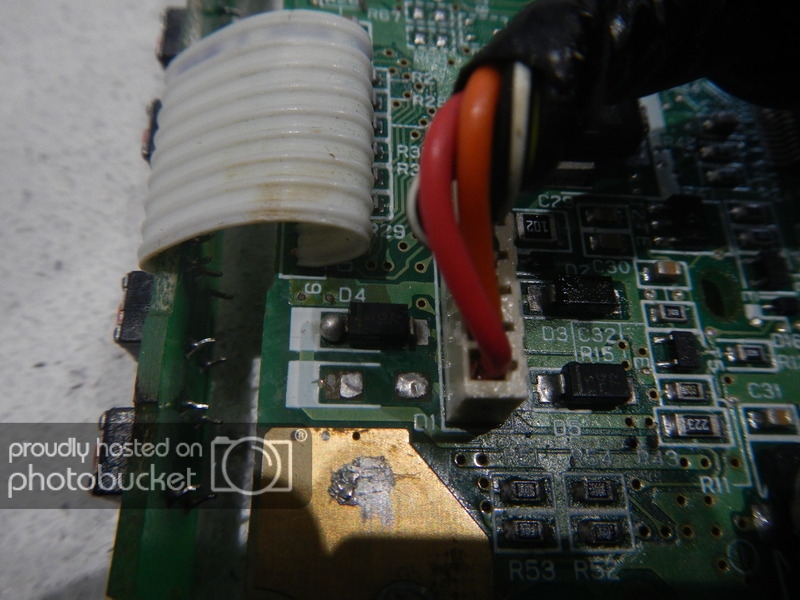

two of the diodes suffered some corrosion around the legs which caused the display to fail.

Ive sourced what i think should be suitable replacements for soldering back on to the board.

Before i do that i wanted to check the condition of the solder pads.

From the photos can you guys tell if the pads shown in the pic ( where one of the diodes has been removed) are in usable condition?

Ive given them a clean up with electrical contact cleaner but they dont look great. Im not sure if they are badly corroded or just need more cleaning!

is there any way i can check them with a multimeter before starting any soldering?

Im not an expert on this so thought i see if i might need to do anything else before attempting to solder the new items