Learn about the Barebones PCB manufacturing process and you might just use it to create your next project!

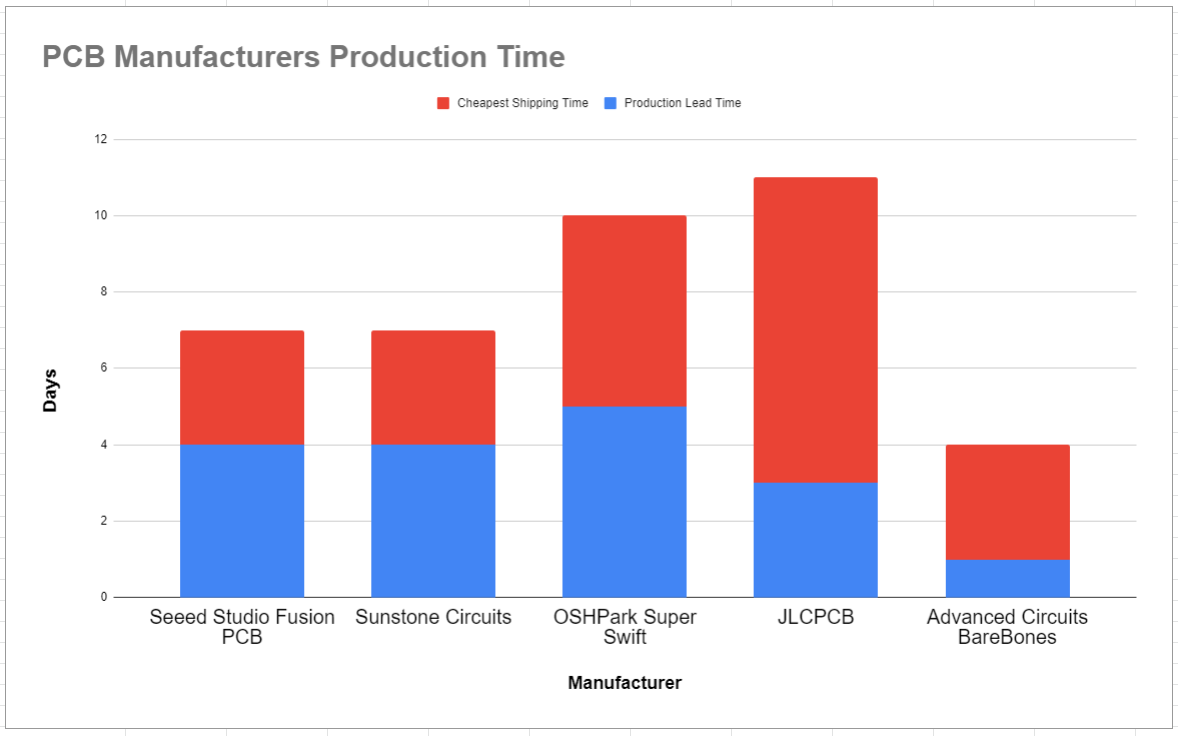

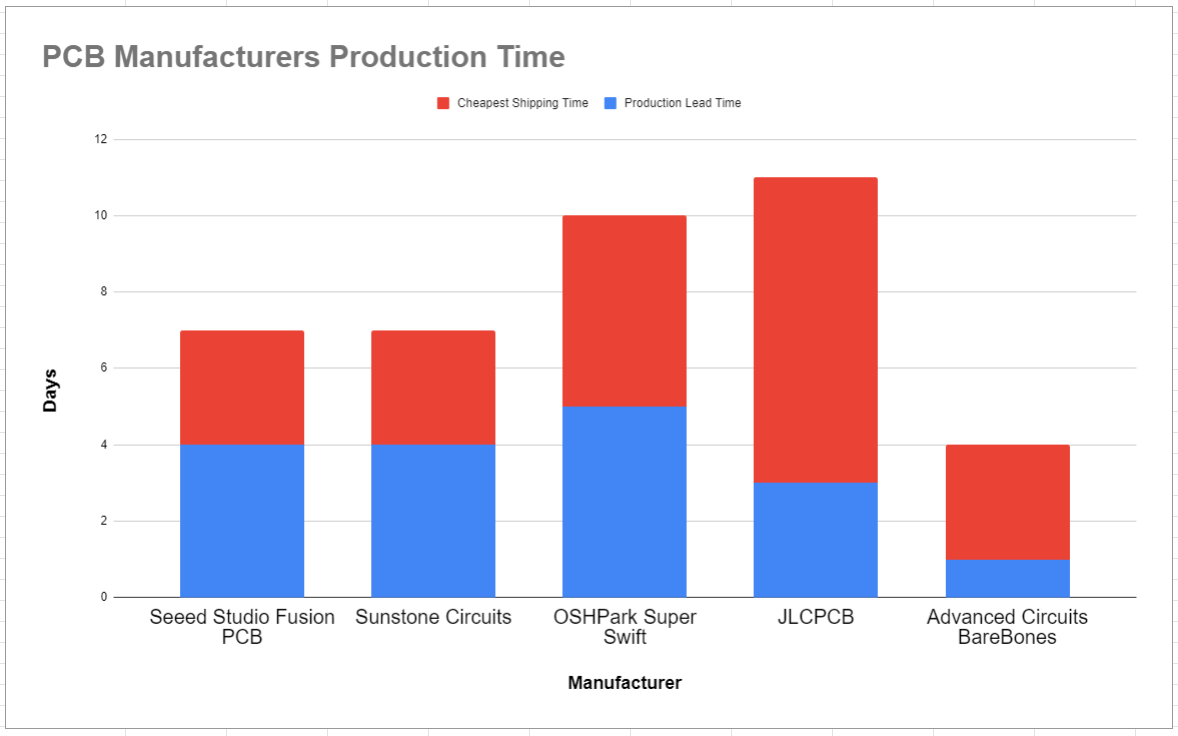

One major challenge for anybody designing a new product involving a printed circuit board is the turnaround time for getting prototype PCBs made. Often, this turnaround time is due to a few different factors: the manufacturing process itself and getting boards shipped in from overseas. Chances are good it can take a couple of weeks between the time you place an order to the time your PCBs are delivered. All of this waiting makes the process of iterating on PCB designs slow, sometimes frustratingly so.

Aside from various methods of making PCBs in-house, like CNC routing, using perf board, or DIY etching, a good way of accelerating your PCB prototyping process is using a service from Advanced Circuits called BareBones PCB. The BareBones service is specifically offered to be one of the fastest methods for getting professionally-made PCBs.

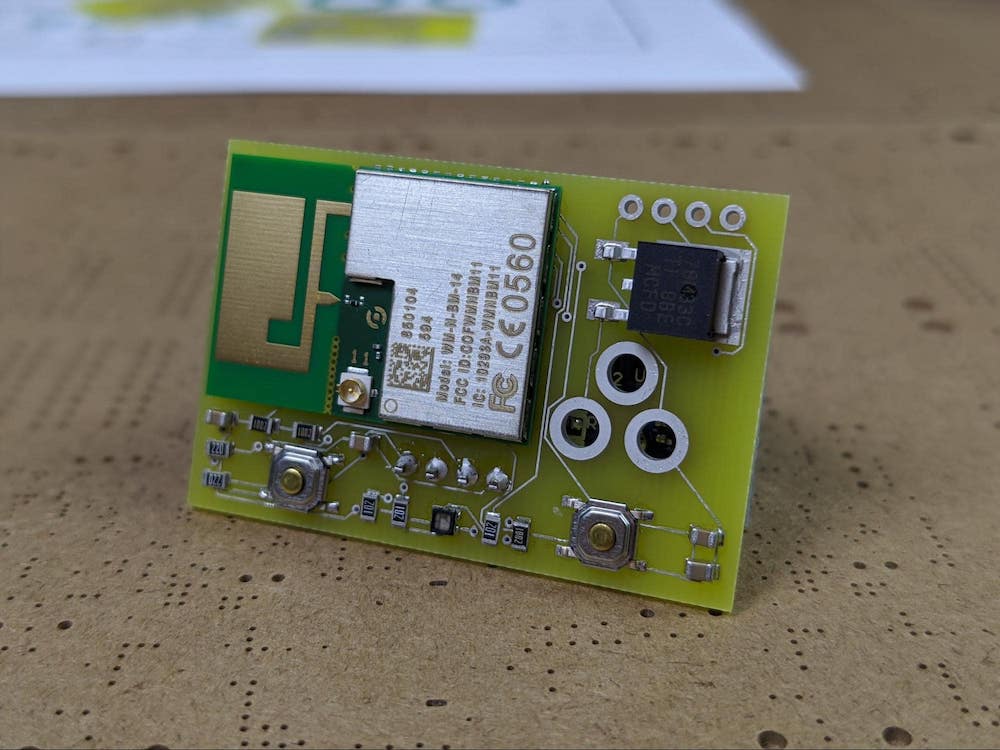

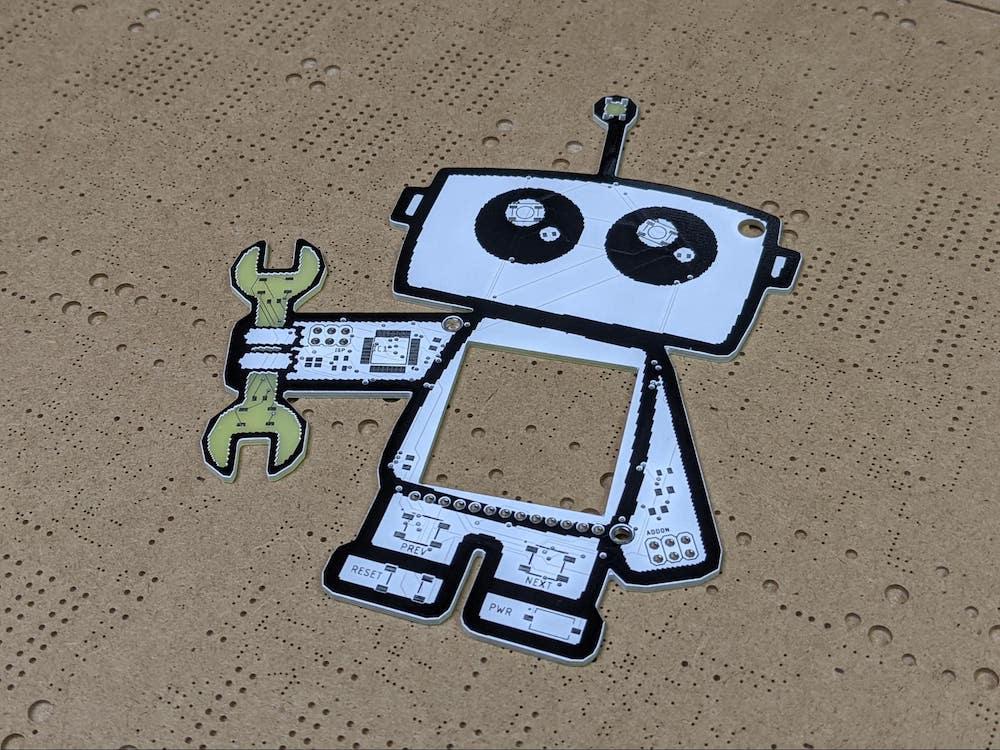

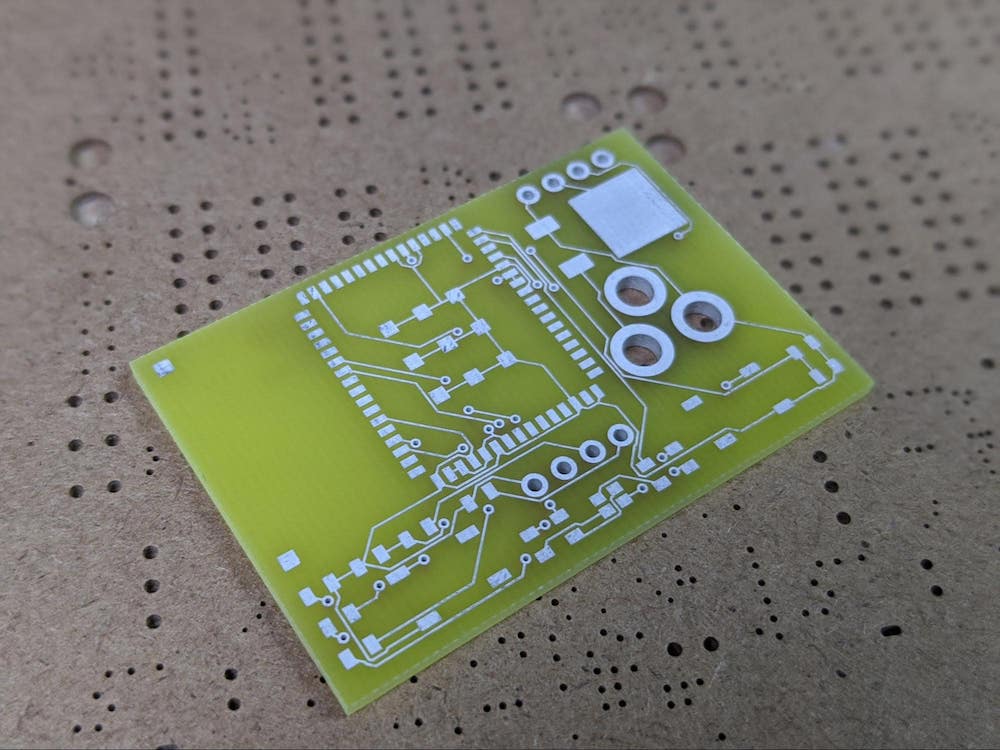

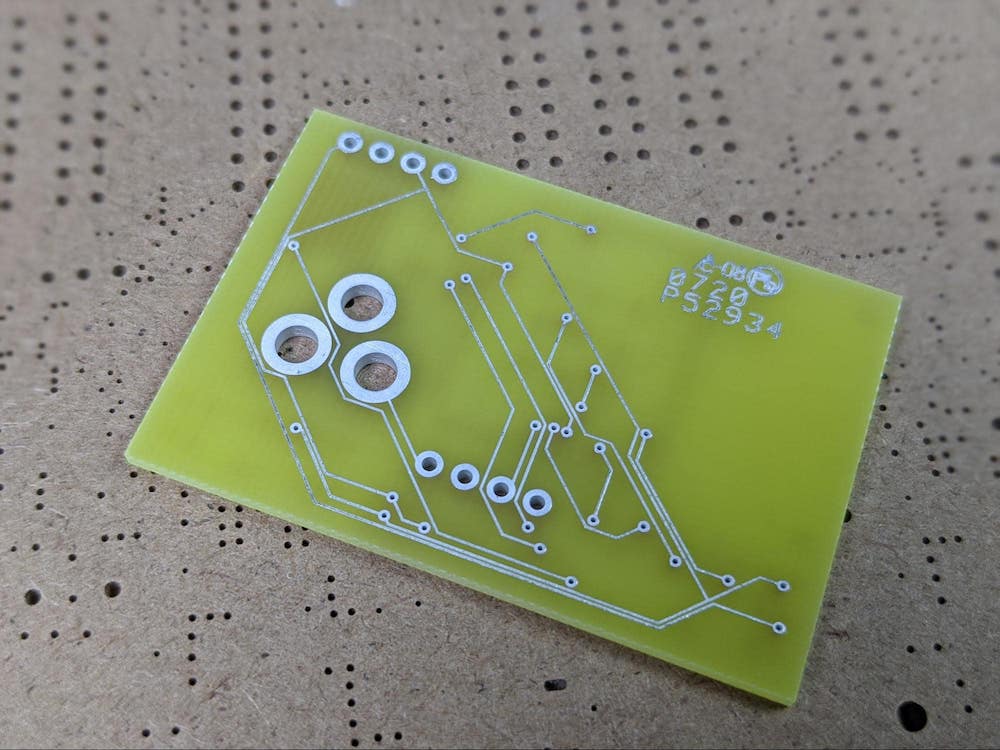

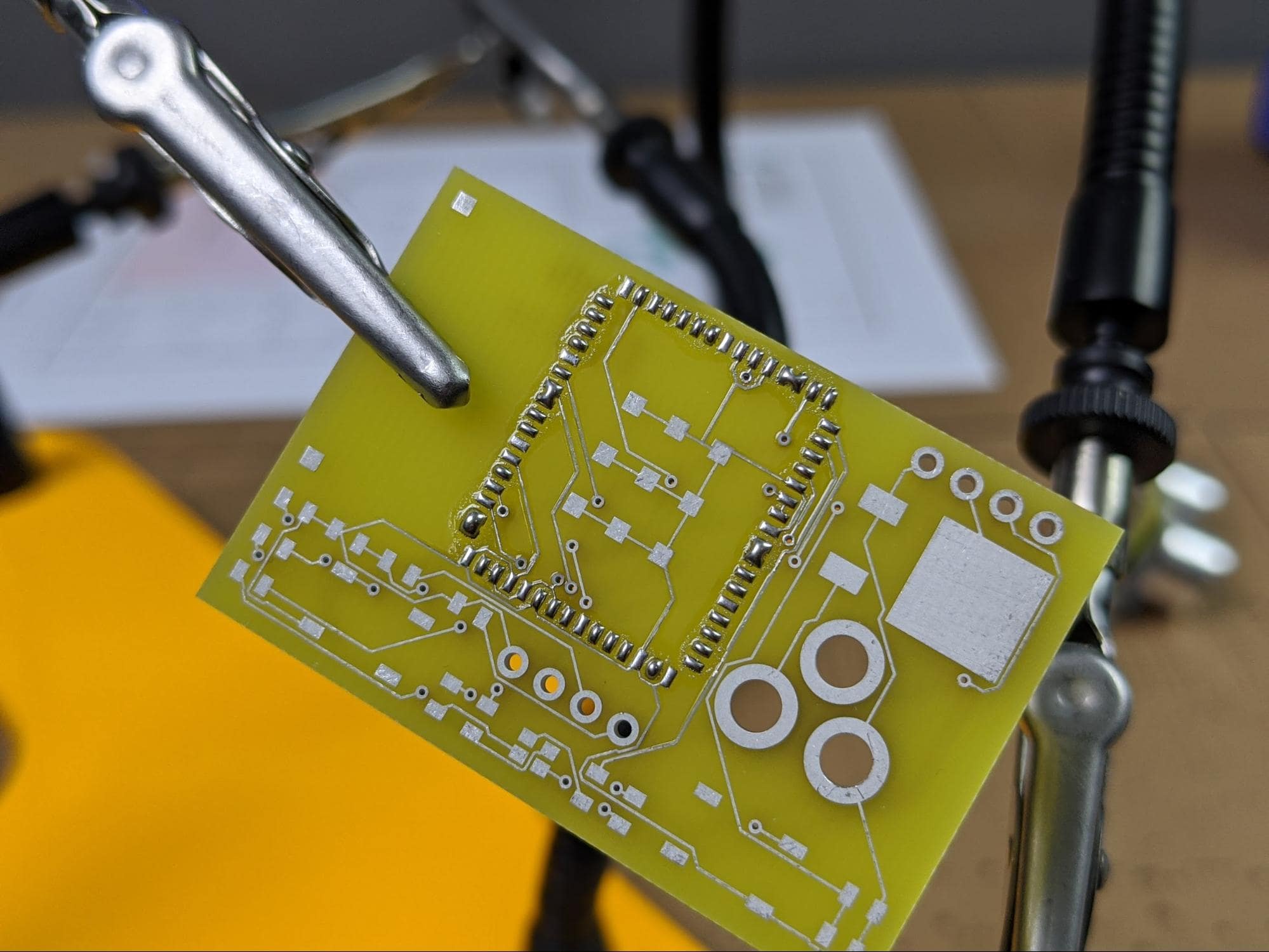

A BareBones PCB with components mounted.

What is Advanced Circuits BareBones PCB?

Advanced Circuits is a U.S.-based PCB manufacturer. BareBones is one of several PCB manufacturing options the company offers, including more traditional 2- and 4-layer panels..

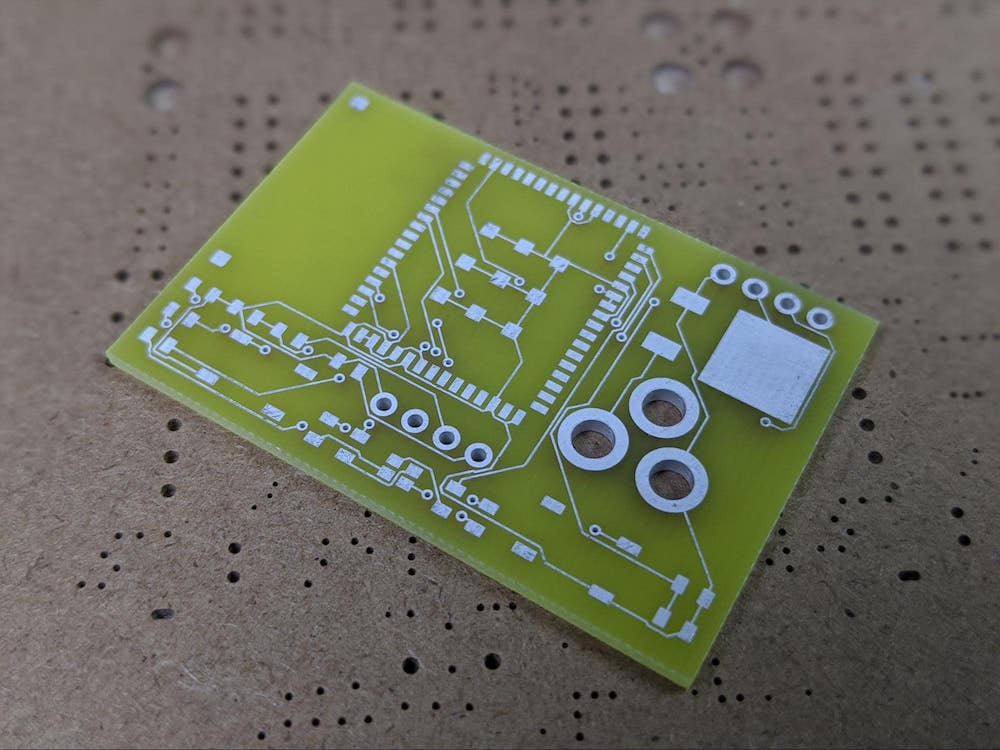

The difference between the BareBones services and other PCB manufacturing options is that, with BareBones PCB, Advanced Circuits cuts out most of the normal steps in making a PCB in order to expedite the manufacturing process. The BareBones boards have no soldermask, no silkscreen, and no internal cutouts. Basically, the boards are bare FR4 with etched copper.

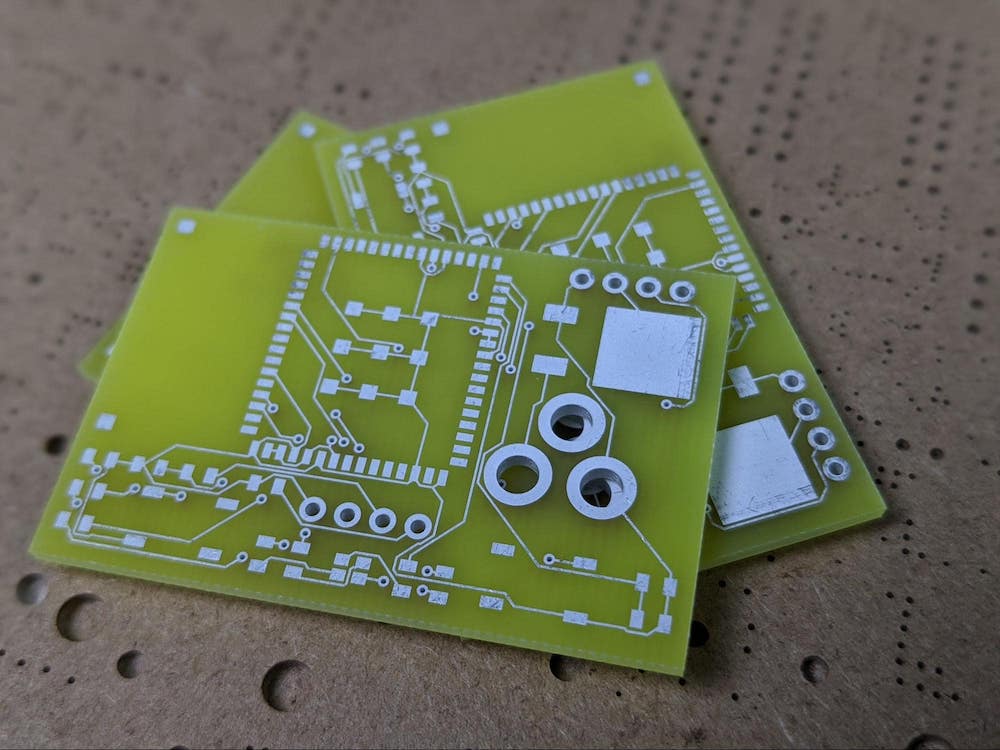

The BareBones PCBs are simply etched copper on bare FR4. They lack a solder mask and silkscreen.

This stripped-down manufacturing process is the secret to how Advanced Circuits achieves a one-day turnaround time for making PCBs. This, combined with the fact that Advanced Circuits operates in the U.S., means you can have your prototype PCBs in hand only a few days after placing your order.

Bonus: Advanced Circuits often sends popcorn with your PCBs!

How to Order From Advanced Circuits BareBones PCB

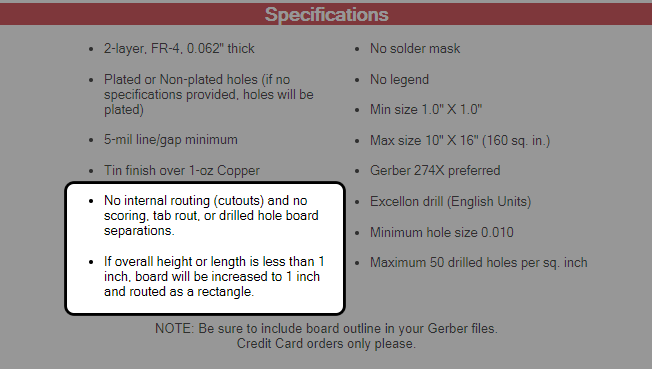

The process for ordering PCBs from Advanced Circuits is about the same as the process for any other PCB manufacturer. The biggest differences between using the BareBones services compared with other manufacturing options, aside from the missing solder mask and silkscreen, are a couple of restrictions on design features.

BareBones PCB Design Restrictions

First, your design cannot incorporate internal cutouts. This means that, aside from holes, you cannot order a design with areas routed out of the board.

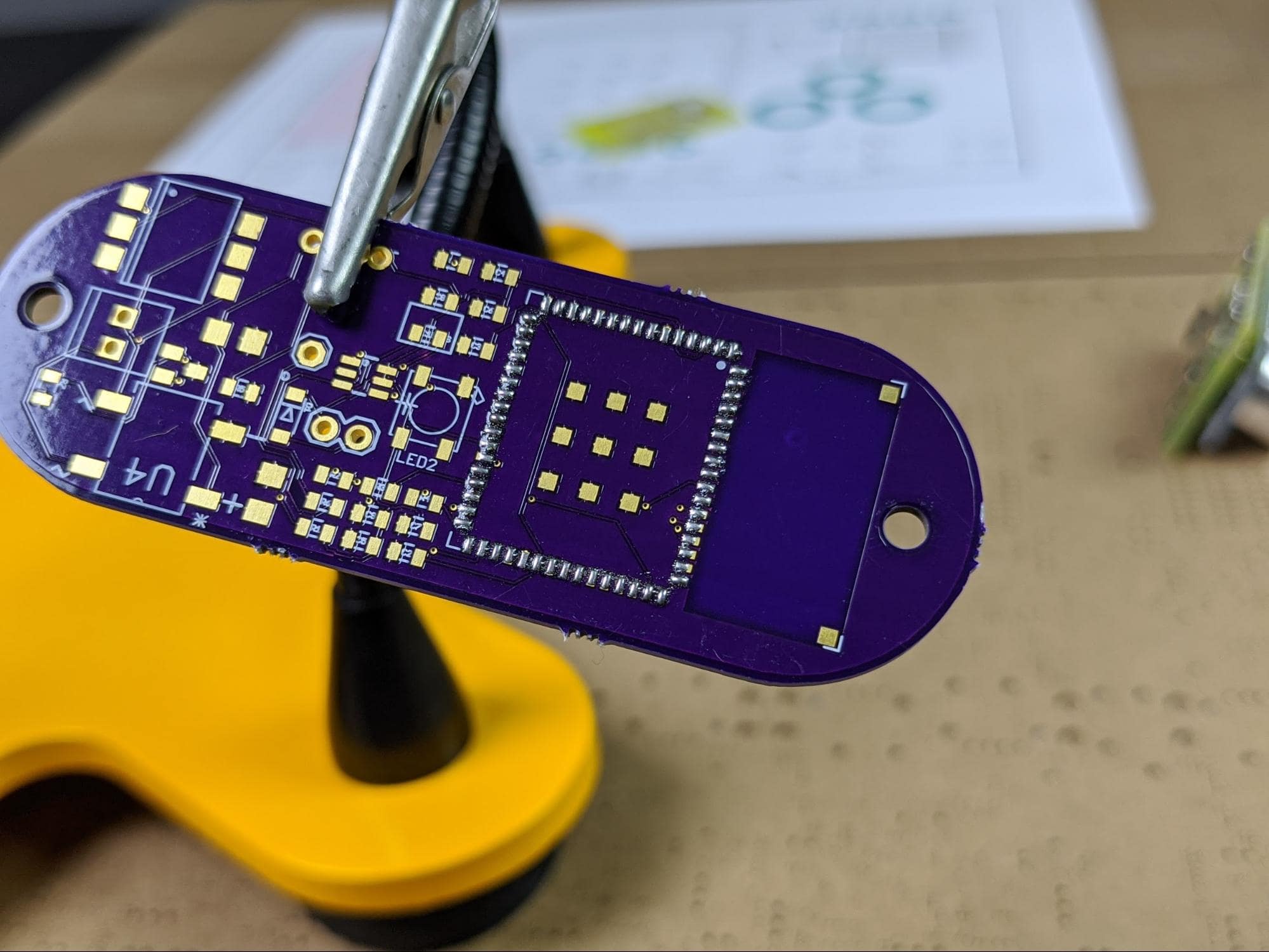

The square cutout in this Maker Pro robot PCB is an example of an internal cutout, which is not supported by Advanced Circuits BareBones PCB.

The second restriction in the specifications for the BareBones PCB service is that the design must be larger than one inch in each dimension. If your design is under one inch in any dimension, BareBones PCB will automatically expand the outline of your board so that it is at least one inch.

Creating Gerber Files for BareBones PCB

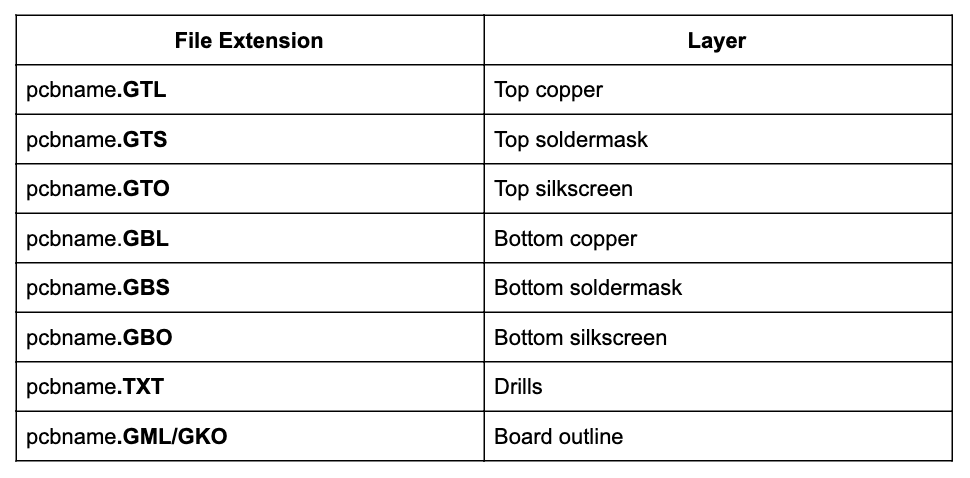

Once you have a completed design that conforms to the BareBones specifications, the next step is to create a set of Gerber files from your PCB design. Gerber files are the industry-standard method of representing a PCB design for manufacturing. Gerbers are a set of files with each file representing a different part of the design.

Advanced Circuits BareBones PCB uses only a few of these layers:

- Top copper

- Bottom copper

- Drills

- Board outline

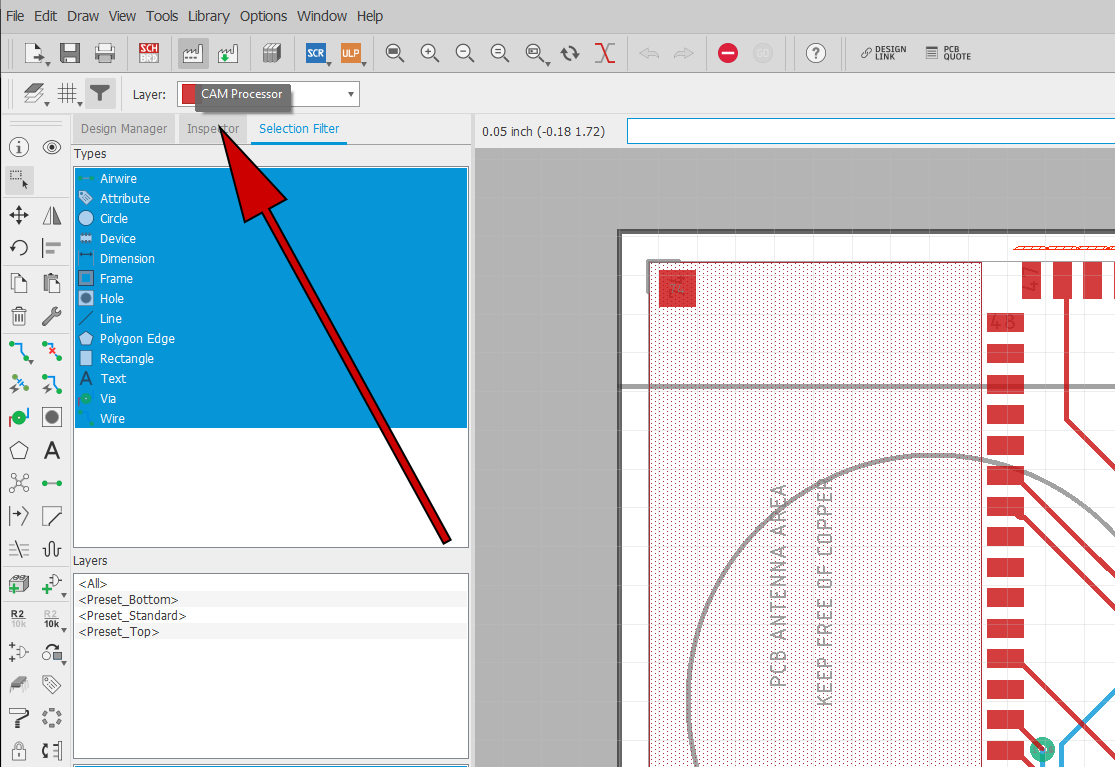

However, in Autodesk Eagle, the CAM processor used to generate Gerber files just makes the whole set of files automatically. Knowing this, it is easiest to create a full set of Gerber files and upload all of them.

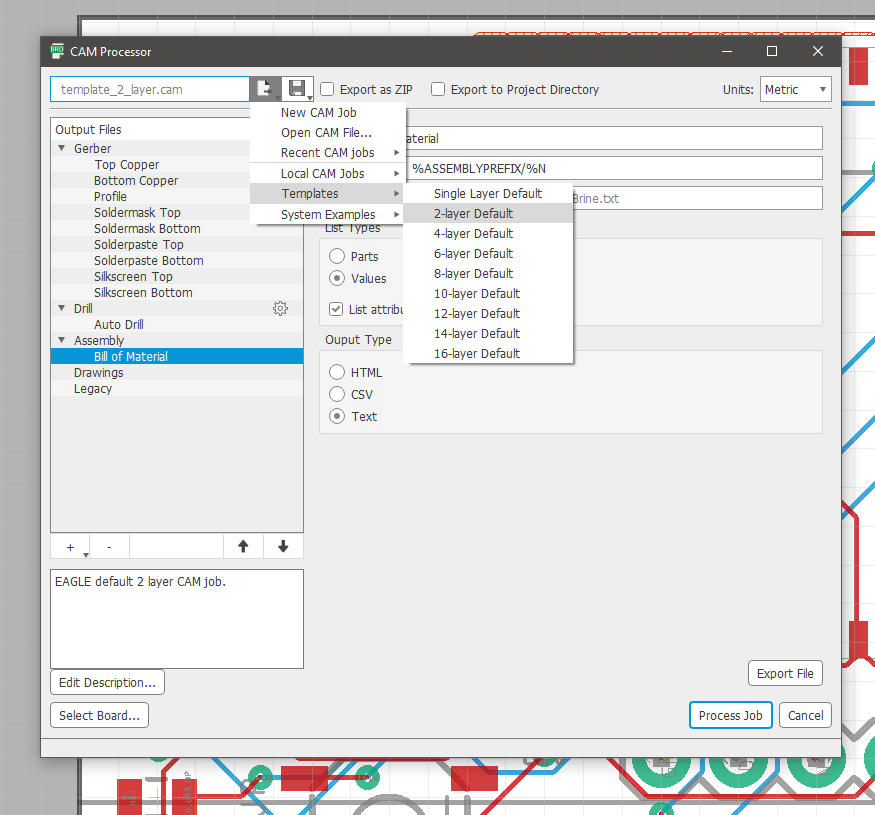

In Autodesk Eagle, begin the process of generating Gerber files by clicking on the CAM processor icon in the toolbar.

Then, from the CAM processor dialog box, press the Load job profile button. For this project, we will be using a standard 2-layer CAM template. To select this template, navigate to Templates > 2-layer Default.

After selecting the template, press the Process Job button. Then, save the .zip file containing your Gerbers.

Ordering BareBones PCBs

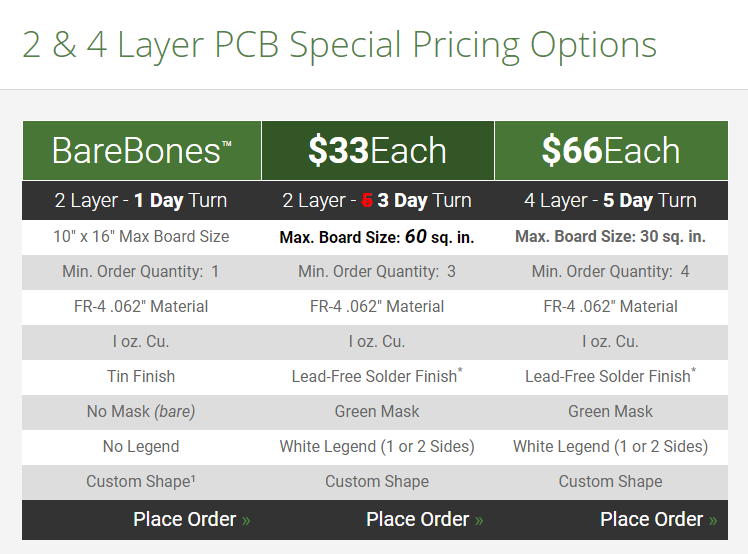

Now that you have a set of Gerber files for your design, you can head over to the Advanced Circuits website. There are a couple of different PCB manufacturing options available. In this case, of course, we will select the BareBones Place Order button.

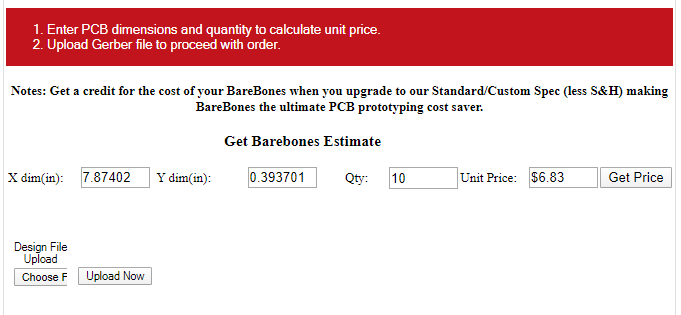

After logging in or creating an account, the first information to enter on the order form is the dimensions of the PCB. Note that the form uses inches rather than metric measurements. As is the case with many PCB manufacturing services, the cost-per-board is largely dependent upon the size of the PCB. Therefore, once you enter the dimensions of your board and the quantity you need, you will be able to get a price quote.

Next up, we can upload the .zip file containing the Gerber files we created earlier. Once you click the Upload Now button, Advanced Circuits proceeds with collecting your shipping and payment information to complete your order.

After you place your order, your PCBs should ship the following day and arrive at your doorstep in four or five business days — that is very quick for PCB manufacturing.

Soldering on BareBones PCBs

The BareBones PCB service from Advanced Circuits is an excellent choice for getting your PCBs manufactured and delivered quickly, so you can keep testing and iterating on your design without waiting weeks between prototypes. You could potentially do two or even three iterations on your prototype design in the time it would take to get a single prototype board from other manufacturers. However, the speed does come at a cost. There is a reason solder mask exists and that most PCBs use solder mask to cover traces and the negative space on the board.

Solder mask helps to prevent solder bridges from forming between closely-spaced PCB pads. It is made from a material to which solder does not stick, so the surface tension of the molten solder during reflow soldering tends to pull the solder onto the pads. However, with the BareBones PCBs, which lack solder mask, the solder will have a much greater tendency to form bridges between pads on your board.

This is a big potential issue because these bridges can cause short circuits that can cause your circuit to malfunction or even destroy your electronics. Therefore, when soldering to the BareBones boards, take care to accurately dispense solder paste to avoid an over-application that can cause solder bridges. Another option, assuming it is practical for your design, is to simply hand-solder the PCBs.

In any event, when using BareBones PCBs, you should certainly take the time to test your PCBs before connecting them to power.

Reviewing the Ways to Cut PCB Prototyping Time

Getting PCB prototypes manufactured can take a long time between the manufacturing process itself and the time required for overseas shipping. It can take a couple weeks between the time you place an order and the day you receive your prototype PCBs. One option for speeding up this time frame and thus decreasing the time between prototype iterations is a PCB manufacturing service called BareBones PCB.

BareBones PCB offers a turn-around time of one day. Including about three days for shipping means you can have prototype PCBs in hand well within a week of placing an order.

The BareBones PCB service is able to produce PCBs quickly by eliminating several of the typical steps for most PCB manufacturing. PCBs from BareBones PCB lack soldermask and silkscreen. The service also does not allow internal cutouts.

Reducing the manufacturing steps allows these BareBones PCBs to be manufactured quickly, allowing you to iterate your design quickly. However, soldering on the board is more difficult without a soldermask because closely-spaced pads are more likely to form solder bridges.