So I bought a new , unused electric motor off a mate cheaply but it didn’t come with a power cord wired in.

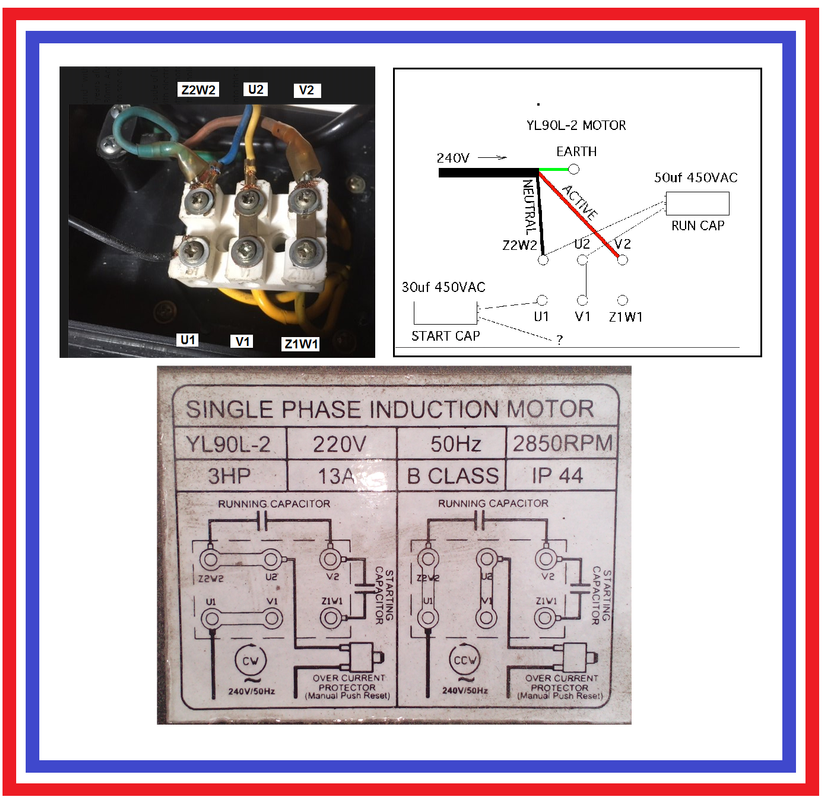

It is a 3HP , 13.7 amp , 2800RPM single phase 240 volt YL90-2 . The box it came in says it is a “Powerstar” brand but says YL-S02. It does have YL90-2 stamped on the nameplate of the motor though so presume they labelled the box wrongly. There is no wiring diagram on the underside of the terminal box cover. What is the correct way to wire this ? My daughter is a third year apprentice electrician but has no experience with electrical motors. She does however have a Fluke multimeter that we can use to test the wires inside the box should that be necessary.

From the photos, obviously the blue cap (250 microfarads) is the start and the black (50 microfarads) is the run. There is also a thermal overload switch in there to complicate matters.

I have a 15amp circuit to run this on and the motor will be used on a bricksaw.

Yes, I am just a humble carpenter so keep it as simple as possible.

Many thanks to anyone who can point me in the right direction here.

It is a 3HP , 13.7 amp , 2800RPM single phase 240 volt YL90-2 . The box it came in says it is a “Powerstar” brand but says YL-S02. It does have YL90-2 stamped on the nameplate of the motor though so presume they labelled the box wrongly. There is no wiring diagram on the underside of the terminal box cover. What is the correct way to wire this ? My daughter is a third year apprentice electrician but has no experience with electrical motors. She does however have a Fluke multimeter that we can use to test the wires inside the box should that be necessary.

From the photos, obviously the blue cap (250 microfarads) is the start and the black (50 microfarads) is the run. There is also a thermal overload switch in there to complicate matters.

I have a 15amp circuit to run this on and the motor will be used on a bricksaw.

Yes, I am just a humble carpenter so keep it as simple as possible.

Many thanks to anyone who can point me in the right direction here.