Hi and welcome to Electronics Point

Before I answer your question, here are three comments about the design.

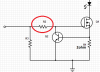

1. You should always use a decoupling capacitor on the 555. That is a 0.1 µF ceramic capacitor, or similar, connected between pin 8 and pin 1 as close as possible to the chip. Soldering it directly between the IC pins on the underside of the circuit board is a good idea. This ensures that the 555 will operate (reasonably) reliably even with all the electrical interference you get from the automotive circuitry when the engine is running.

2. Switching R2 between 10k and 330Ω will change the flash rate, but it will also change the duty cycle (the ratio between ON and OFF times) very noticeably, because 330Ω is less than R1. If you want the duty cycle to remain round 50% you should either use much higher values for R2, e.g. 100k and 3.3k, or switch C1.

That could be done pretty easily by making C1 3.3 µF (which will give you the fast flash rate) and connecting a 100 µF capacitor through a switch so that when you close the switch, the 100 µF capacitor is connected across (in parallel with) the 3.3 µF capacitor. When the switch is closed, the LEDs will flash slowly; when the switch is open, they'll flash quickly.

3. Sensitive electronic circuitry can be damaged by high-voltage noise from automotive supplies, and especially by "load dump" (

http://en.wikipedia.org/wiki/Load_dump). You can add circuitry to protect it, or in the meantime, make sure you unplug it from the cigarette lighter before you turn the ignition off.

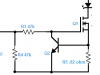

The circuitry at the right side is called a "constant current sink". It regulates the current through the LEDs to be about 0.8A when the 555's output is high.

If each LED has a forward voltage that could be as high as 3.8V, and you connect three of them in series, you need (3 × 3.8) = 11.4V. There will also be nearly 1V dropped across the MOSFET and R5, so this can't be guaranteed to work properly using a supply voltage less than about 12.4V. Even if the LED forward voltage is only 3.6V you would still be cutting it very fine.

So you can only connect up to two of these LEDs in series. This means you would need a second constant current sink circuit for each circuit, to drive the third LED. Just repeat the circuit consisting of R3, Q2, Q1 and R5, connecting the new R3 to pin 3 of the 555 along with the existing R3. BTW, R4 isn't needed.