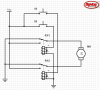

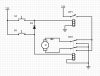

I have a DC motor and I have 2 momentary switches as well as a DPDT Relay.

I would like to use each switch to control the direction of the motor but only when the switches are depressed. When no switch is depressed I want the motor to be idle.

Is this possible with my setup?

I am repairing a lift chair for my grandma and the components that were damaged are no longer available.

I would like to use each switch to control the direction of the motor but only when the switches are depressed. When no switch is depressed I want the motor to be idle.

Is this possible with my setup?

I am repairing a lift chair for my grandma and the components that were damaged are no longer available.