Hi all,

I have been messing around with a simple voltage regulator circuit on a breadboard.

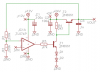

What it's supposed to do is take a 5V square wave (microcontroller PWM output) give it some set voltage gain, current gain and load regulation. The final circuit would more complex, this is simplified for breadboarding. The circuit works in SPICE (with some oddities such as a kind of overshoot on the rising edge with a diminishing oscillation before it stabilises on the correct "on" voltage)

In lieu of any real power supply, I'm using a spare one I have from a printer, which puts out +15V and +32V with a common ground. Looking at the power supply on a scope, there's no real noticable 50Hz noise on it that the circuit might be amplifying. However, within my regulator's feedback loop, there's a 50Hz half wave rectified sine wave swamping my actual signal, and I can't work out where it's coming from. This is present even when there is no input signal.

A schematic is attached, the +12V is really +15Vdc, and the +24V is really +32Vdc, the diodes are there to bias T1 and allow it to go into cut off, since in SPICE the TL074 output won't swing down below a couple of volts above its negative rail, although they seem to make little difference so far on the breadboard.

Any ideas where this noise is coming from?

Cheers,

Matt

PS. The final circuit may well end up as a separate regulator and transistor switch, this one's just something i wanted to try out

I have been messing around with a simple voltage regulator circuit on a breadboard.

What it's supposed to do is take a 5V square wave (microcontroller PWM output) give it some set voltage gain, current gain and load regulation. The final circuit would more complex, this is simplified for breadboarding. The circuit works in SPICE (with some oddities such as a kind of overshoot on the rising edge with a diminishing oscillation before it stabilises on the correct "on" voltage)

In lieu of any real power supply, I'm using a spare one I have from a printer, which puts out +15V and +32V with a common ground. Looking at the power supply on a scope, there's no real noticable 50Hz noise on it that the circuit might be amplifying. However, within my regulator's feedback loop, there's a 50Hz half wave rectified sine wave swamping my actual signal, and I can't work out where it's coming from. This is present even when there is no input signal.

A schematic is attached, the +12V is really +15Vdc, and the +24V is really +32Vdc, the diodes are there to bias T1 and allow it to go into cut off, since in SPICE the TL074 output won't swing down below a couple of volts above its negative rail, although they seem to make little difference so far on the breadboard.

Any ideas where this noise is coming from?

Cheers,

Matt

PS. The final circuit may well end up as a separate regulator and transistor switch, this one's just something i wanted to try out