I am just in the initial "I wonder if I could" stage of designing a current sensing device for my R/C model aircraft.

The idea is a unit that plugs in between the battery and the aircraft to see how much current is being used when the motor(s) are running, to better get an idea of battery life under use when setting things up. I'm planning on using the 100A version of the ACS758 https://www.allegromicro.com/~/media/Files/Datasheets/ACS758-Datasheet.ashx

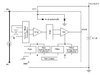

My question is, can I use the battery under test as the power source for my MCU and associated circuitry (LCD, etc)? Or is this going to cause problems for the measurement? I attached a picture I found on a website that shows typical connections. but it doesn't show where the Arduino is getting its power from.

Anyone have any ideas on this? It would be nice to not have a separate battery to power the unit.

Thanks

Andy

The idea is a unit that plugs in between the battery and the aircraft to see how much current is being used when the motor(s) are running, to better get an idea of battery life under use when setting things up. I'm planning on using the 100A version of the ACS758 https://www.allegromicro.com/~/media/Files/Datasheets/ACS758-Datasheet.ashx

My question is, can I use the battery under test as the power source for my MCU and associated circuitry (LCD, etc)? Or is this going to cause problems for the measurement? I attached a picture I found on a website that shows typical connections. but it doesn't show where the Arduino is getting its power from.

Anyone have any ideas on this? It would be nice to not have a separate battery to power the unit.

Thanks

Andy