Sir Tiba . . . . .

Code dates certainly tell us that unit was the last of their 1993'ish models vice the first 1988 ones of production..

In looking at the whole unit, the logic for the connector closest to the set of relays would be for it going to the shredder motor.

With

TWO relays being used, there is then the capability for two sets of SPDT contacts usages, to then be able to reverse the direction of the shreddder motor for paper jam releasing.

With all of the MANY CMOS and and nand gates being associated with the unit, the resultant final logic condition would detect if there were any initial faults , if not finding any faults , then a relay closes to start a paper shredding.

With you confirming main board low voltage supply power being produced, no faults LED's being lit up and the noise of a closing relay.

With the units meager power needs, looks like that Photo #3 of the 4 pin DIP FWB rectifier on the board creates the 12 VDC with assistance of the two E-caps on the main board, nearby to the 7812 . . . 3 term regulator.for the relays coil supply.

Possibly there is being a Zener diode derived sub supply level of ? 5VDC ? since the adjunct 6pin DIP encased TCA 315 Siemens comparator function can be used at TTL logic levels.

What I am really inclined to suspicion, in knowing of the age of this unit and its potentail run time, is being the units shredder motor, considering that there is no associated fuse or tripped, standard or thermal breaker being at fault instead .

Some how, I want to expect the power needs and motor type will have some gear train associated with it for developed torque.

Additionally, I am expecting it

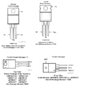

NOT to be the top motor shown below,

BUT, instead, a more

HEFTY AC-DC brushed series wound induction motor.

Two types of brush assemblies are typically found used on those units.

The left pic has the imbedded copper braid wiring within the center of the rectangular brush element with a compression spring at the

RED arrow . That maintains pressure towards the commutator segments. Those types usually work all the way down to only the nub of a brush remnant.

The brush holder type to the right is dependent upon a coiled clocksprings pressure to hold tension against the brush at that units depicted

RED arrow.

Frequently, after just about reaching its tensioning limit, the spring will leave the brush with progressively less pressure and the increasing of arcing and a blackening of the commutator segments. Eventually, a loose, wobbly brush will result in loss of contact to the commutator and an open circuit.

TWO FORMATS OF BRUSH HOLDERS . . . ELECTRO-MECHANICAL ASPECTS . . . .

Thaaaaaaaaaaasssssit . . . . .

73's de Edd . . . . .

When I told my doctor about my progressively frequent loss of memory . . . . . he made me pay in advance.

.