Hello everyone. I'm new here and have enjoyed reading the other threads. I have a project I'm in the final stages with and need some consultation before I do the final installation.

Project Overview:

I replaced my mechanical timers for my pool pumps with an Arduino / ESP8266 microcontroller solution

Components:

Wi-Fi based microcontroller controller with (3) relay chains.

(1) 110VAC relay switch for pool like (5VDC relay coil) (http://pic.hkyrd.com/index.php?f=Ly8vdXBsb2FkcGljL1NLVS9UMS9UMTA5Ni9UMTA5NnolMjAoMSkuanBn&u=ODY3NTU=)

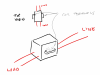

(2) 220VAC relay/contactor switches for pool pump and booster pump (24AC relay coil) (http://www.homedepot.com/p/Packard-...mp-Definite-Purpose-Contactor-C240A/203565786). Because my microcontroller doesn't deal with 24VAC, I'm using more of the relays above to switch in 24VAC to these two relays.

FYI: Raspberry PI running an MQTT server that is also involved with other home control components. This is my centralized control point for all gadgets

Problem:

I have everything working except for one issue. When I activate the pool pump relay, everything is fine, but when I close the other relay for the booster pump (main pump must be on to run booster) both pumps stop. I confirm that the smaller relays are closed, so I there is a problem on the 24VAC side. I'm wondering if I don't have enough amperage on my 24VAC power supply. I cannot seem to find any educational information for me to tell what I need to close them.

Concerns:

1) Do I need some resistance for the 24VAC relay/contactors? I have nothing there right now. Perhaps this is why I'm not able to close two at once?

2) Flyback voltage: I believe I'm protected because I'm using the two smaller relays to control the 24VAC coil line as I mentioned above. So, basically two relays for each pump. The smaller relay gets switched from my microcontroller and it closed the 24VAC for the contactor relays. This allows me to keep a AC from being anywhere inline with my project and I just wanted to keep it separate plus I thought it would protect the microcontroller.

I hope that was clear!

Many thank yous for helping the less educated!

Project Overview:

I replaced my mechanical timers for my pool pumps with an Arduino / ESP8266 microcontroller solution

Components:

Wi-Fi based microcontroller controller with (3) relay chains.

(1) 110VAC relay switch for pool like (5VDC relay coil) (http://pic.hkyrd.com/index.php?f=Ly8vdXBsb2FkcGljL1NLVS9UMS9UMTA5Ni9UMTA5NnolMjAoMSkuanBn&u=ODY3NTU=)

(2) 220VAC relay/contactor switches for pool pump and booster pump (24AC relay coil) (http://www.homedepot.com/p/Packard-...mp-Definite-Purpose-Contactor-C240A/203565786). Because my microcontroller doesn't deal with 24VAC, I'm using more of the relays above to switch in 24VAC to these two relays.

FYI: Raspberry PI running an MQTT server that is also involved with other home control components. This is my centralized control point for all gadgets

Problem:

I have everything working except for one issue. When I activate the pool pump relay, everything is fine, but when I close the other relay for the booster pump (main pump must be on to run booster) both pumps stop. I confirm that the smaller relays are closed, so I there is a problem on the 24VAC side. I'm wondering if I don't have enough amperage on my 24VAC power supply. I cannot seem to find any educational information for me to tell what I need to close them.

Concerns:

1) Do I need some resistance for the 24VAC relay/contactors? I have nothing there right now. Perhaps this is why I'm not able to close two at once?

2) Flyback voltage: I believe I'm protected because I'm using the two smaller relays to control the 24VAC coil line as I mentioned above. So, basically two relays for each pump. The smaller relay gets switched from my microcontroller and it closed the 24VAC for the contactor relays. This allows me to keep a AC from being anywhere inline with my project and I just wanted to keep it separate plus I thought it would protect the microcontroller.

I hope that was clear!

Many thank yous for helping the less educated!