Hi everyone,

I am a mechanical engineer who has recently started to experiment in electronics. I've recently started on a simple circuit that is required to drive a piezo disk with a relatively high amplitude (~80 V) at a low frequency, ranging from about 10 Hz to 150 Hz. The circuit is described below.

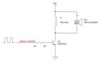

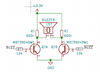

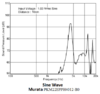

The main stage is a DC/DC boost converter circuit, where the MOSFET is switched at 1 kHz from an AT-Tiny PWM. The generated DC voltage (about 80VDc), is then modulated at the required low frequency with another N-Channel MOSFET. The frequency is defined by a 47k potentiometer mapped to output a second PWM signal between 1 and 150 Hz using an analog input to the ATTiny.

The circuit works as intended. However, I don't know if there is anything wrong with the circuit that may damage components over time. For example, should I be using P-Channel MOSFETs instead? Also, when I switch the right side MOSFET on, the voltage just goes straight to ground, there is no resistances except for the inductor, am I essentially shorting the circuit?

Again, very new to this, please excuse any dumb mistakes.

Thanks for the help!

I am a mechanical engineer who has recently started to experiment in electronics. I've recently started on a simple circuit that is required to drive a piezo disk with a relatively high amplitude (~80 V) at a low frequency, ranging from about 10 Hz to 150 Hz. The circuit is described below.

The main stage is a DC/DC boost converter circuit, where the MOSFET is switched at 1 kHz from an AT-Tiny PWM. The generated DC voltage (about 80VDc), is then modulated at the required low frequency with another N-Channel MOSFET. The frequency is defined by a 47k potentiometer mapped to output a second PWM signal between 1 and 150 Hz using an analog input to the ATTiny.

The circuit works as intended. However, I don't know if there is anything wrong with the circuit that may damage components over time. For example, should I be using P-Channel MOSFETs instead? Also, when I switch the right side MOSFET on, the voltage just goes straight to ground, there is no resistances except for the inductor, am I essentially shorting the circuit?

Again, very new to this, please excuse any dumb mistakes.

Thanks for the help!