Hi,

I have managed to make some changes to salvage an emergency lamp that had 4 lead acid batteries connected in parallel with a charging board.

I replaced the board with that from a universal charger that takes Li / NiMH batteries upto 9 V.

I connected this to 3 NiMH AA batteries in series (total 3.5V) housed in a battery case.

The unit has 1 x 2 way switch and an simple on/off switch which I would like to restore to their original purpose. The on/off is currently connected correctly so that I can turn the lamp on and off as expected.

Basically, what I would like to do is to set the 2 way switch in such a way as to allow the LED lights to automatically come on when the electricity supply to the charging board is interrupted such as when there is a power outage.

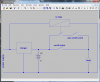

Is there a simple circuit that can be incorporated?

I can send further details / diagram to show what I have done so far.

I have managed to make some changes to salvage an emergency lamp that had 4 lead acid batteries connected in parallel with a charging board.

I replaced the board with that from a universal charger that takes Li / NiMH batteries upto 9 V.

I connected this to 3 NiMH AA batteries in series (total 3.5V) housed in a battery case.

The unit has 1 x 2 way switch and an simple on/off switch which I would like to restore to their original purpose. The on/off is currently connected correctly so that I can turn the lamp on and off as expected.

Basically, what I would like to do is to set the 2 way switch in such a way as to allow the LED lights to automatically come on when the electricity supply to the charging board is interrupted such as when there is a power outage.

Is there a simple circuit that can be incorporated?

I can send further details / diagram to show what I have done so far.