I am trying to control both the direction and limits of a small DC motor with threaded shaft using components and modules readily available online.

I have a very small DC 6v motor with gear reduction (500rpm) and a 2” threaded shaft. Upon receiving signal (LED on)I need this motor to turn until the threaded object nears the end of shaft then have motor stop until a second signal (LED off) then it will reverse and threaded object on shaft goes all the way back to start position ready to repeat the cycle again.

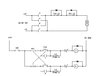

The first trigger event is a 5v LED turning on and the second is it turning off. I am having a problem translating that into a usable signal for a reverse polarity module I am using.

I have a NO switch I am using to test and every click triggers the module to reverse direction as intended but I need my signal to be activated by both the presence of voltage and then the absence of it.

Then I also need power to motor to be cut off when the threaded object reaches the limits of the shaft in both directions. I had intended to use micro switches but if I do this then motor has no power when module reverses.

For the signal could I use a relay module hooking both up both NO and NC to the trigger side of polarity module? Would that end up making a signal (switch on) during both states? If so that would solve the trigger signal problem.

Then I have the limit switches. If a switch cuts off power to motor at end of travel how can I get it to reverse direction when it is time to do so?

It seems like such an easy problem and with all these modules readily available I just have such limited knowledge at this point. I do however suspect that will change…

This is the module I am using for this but am not married to it if a better solution surfaces.

https://www.amazon.com/gp/aw/d/B08922D8TS?psc=1&ref=ppx_pop_mob_b_asin_title

I have a very small DC 6v motor with gear reduction (500rpm) and a 2” threaded shaft. Upon receiving signal (LED on)I need this motor to turn until the threaded object nears the end of shaft then have motor stop until a second signal (LED off) then it will reverse and threaded object on shaft goes all the way back to start position ready to repeat the cycle again.

The first trigger event is a 5v LED turning on and the second is it turning off. I am having a problem translating that into a usable signal for a reverse polarity module I am using.

I have a NO switch I am using to test and every click triggers the module to reverse direction as intended but I need my signal to be activated by both the presence of voltage and then the absence of it.

Then I also need power to motor to be cut off when the threaded object reaches the limits of the shaft in both directions. I had intended to use micro switches but if I do this then motor has no power when module reverses.

For the signal could I use a relay module hooking both up both NO and NC to the trigger side of polarity module? Would that end up making a signal (switch on) during both states? If so that would solve the trigger signal problem.

Then I have the limit switches. If a switch cuts off power to motor at end of travel how can I get it to reverse direction when it is time to do so?

It seems like such an easy problem and with all these modules readily available I just have such limited knowledge at this point. I do however suspect that will change…

This is the module I am using for this but am not married to it if a better solution surfaces.

https://www.amazon.com/gp/aw/d/B08922D8TS?psc=1&ref=ppx_pop_mob_b_asin_title