hi everyone kindly see my setup doc below ! tnx !

is the actual setup going to be OKAY ???

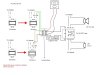

actually it worked, and still working since the last 4 days .. I want to energize the relay whenever EACH or BOTH of the devices closes contact ....

but i think the devices' internal contacts are not carrying both the load of the relay, i think it is only carrying the power supply (12V 1A) intended for the dpdt relay ONLY sir if i'm not mistaken . because the internal contacts of the device can only handle 15W contact rating, whereby the 2 output devices are rated at a total of 22W ... i'm triggering the internal contacts of the devices for more than 10 times a day , and nothing bad happens ...

i just want to know if it will last long without future troubleshooting .. but there will be of course as time goes by . and i also want to know where are these potential spots that will need troubleshooting in the future . tnx

is the actual setup going to be OKAY ???

actually it worked, and still working since the last 4 days .. I want to energize the relay whenever EACH or BOTH of the devices closes contact ....

but i think the devices' internal contacts are not carrying both the load of the relay, i think it is only carrying the power supply (12V 1A) intended for the dpdt relay ONLY sir if i'm not mistaken . because the internal contacts of the device can only handle 15W contact rating, whereby the 2 output devices are rated at a total of 22W ... i'm triggering the internal contacts of the devices for more than 10 times a day , and nothing bad happens ...

i just want to know if it will last long without future troubleshooting .. but there will be of course as time goes by . and i also want to know where are these potential spots that will need troubleshooting in the future . tnx