Hello All.

A new member looking for help as my daughter's favourite garden ornament is no longer working.

We have a solar powered lighthouse (Aldi), but like most cheaper items water will always get in.

I have attached some images to show one of the components has broken off from the circuit board.

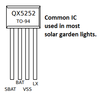

Is it possible to buy a replacement translator, I think it is called and soldered back in place please?

If so what is the component, so I can purchase one and attempt to solder it back.

All the translators I have seen have three 'prongs' but as far as I can make out mine only had two.

But me not knowing a jot about circuitry, is probably completely wrong.

A solar panel is wired to a switch, in the wiring is the panel which has the broken component then onto another board that has the magnetic motor and cogs that will turn the reflective part around the LED.

Please, if anyone can help out, I would be very grateful and of course my daughter will be happy again.

A new member looking for help as my daughter's favourite garden ornament is no longer working.

We have a solar powered lighthouse (Aldi), but like most cheaper items water will always get in.

I have attached some images to show one of the components has broken off from the circuit board.

Is it possible to buy a replacement translator, I think it is called and soldered back in place please?

If so what is the component, so I can purchase one and attempt to solder it back.

All the translators I have seen have three 'prongs' but as far as I can make out mine only had two.

But me not knowing a jot about circuitry, is probably completely wrong.

A solar panel is wired to a switch, in the wiring is the panel which has the broken component then onto another board that has the magnetic motor and cogs that will turn the reflective part around the LED.

Please, if anyone can help out, I would be very grateful and of course my daughter will be happy again.