Hi,

I'm a beginner in electronic design with no courses. I've learned all i know by myself but lots is missing. So i need someone to check this out to see where i've done an error.

I have designed a module to protect a machine at my shop from overheating and stopping production.

The module use a DS18B20 as sensor and when reach 50c trigger a alarm with a buzzer and a led. A 1602 LCD show the temperature and alarm too.

I have done the design, programmed the chip, and tested it on a QL200 prototyping board. It worked flawlessly.

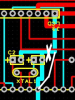

So i continued and designed the pcb using designspark. Now the pcb is etched and fully soldered.

I double checked all the connection and everything seems ok, but it doesn't work. The lcd light up, but nothing show as it is supposed. More than that, the buzzer start to buz after 1 min or like and is not supposed to so until the PIC16F876a tell him to do so.

So i'm a little confused. If someone can check the layout and point out the problem (that i supposed is easy to found but i lack the necessary knwoledge) i would really appreciate.

Don't know if its in the layout or in the board desigh...

Thank you,

Mikael

PS: The R8 resistor pulling the mclr up is missing on the board, i added it manually after so disregard this error, its already corrected.

I'm a beginner in electronic design with no courses. I've learned all i know by myself but lots is missing. So i need someone to check this out to see where i've done an error.

I have designed a module to protect a machine at my shop from overheating and stopping production.

The module use a DS18B20 as sensor and when reach 50c trigger a alarm with a buzzer and a led. A 1602 LCD show the temperature and alarm too.

I have done the design, programmed the chip, and tested it on a QL200 prototyping board. It worked flawlessly.

So i continued and designed the pcb using designspark. Now the pcb is etched and fully soldered.

I double checked all the connection and everything seems ok, but it doesn't work. The lcd light up, but nothing show as it is supposed. More than that, the buzzer start to buz after 1 min or like and is not supposed to so until the PIC16F876a tell him to do so.

So i'm a little confused. If someone can check the layout and point out the problem (that i supposed is easy to found but i lack the necessary knwoledge) i would really appreciate.

Don't know if its in the layout or in the board desigh...

Thank you,

Mikael

PS: The R8 resistor pulling the mclr up is missing on the board, i added it manually after so disregard this error, its already corrected.

Attachments

Last edited: