I want to reduce the size of the fuse so it blows and not the MOV

That will probably not work well. The fuse blows due to overcurrent. The current is a consequence of the MOV becoming conductive due to ovevoltage. So it will always be the MOV that acts first, then the fuse. The fuse is there only to prevent fire that may result from the MOV being stressed by high power when it has been triggered and the trigger condition (overvoltage) persists longer than the MOV can take (MOVs are meant to suppress short spikes only).

You might try a faster fuse with a lower trigger current, but then you risk the fuse being triggered by even a short overvoltage event and then the MOV will be useless afterwards as the fuse is open.

My problem is electricians that don't check the phasing.

Here's the real problem: sloppy workmanship. A MOV is the wrong tool to correct this.

I use the MOV's across the contacts to prevent voltage spikes in the equipment that is downstream

How is that supposed to work? Imho not at all:

- contact open: the full voltage will be across the open contact, so will overvoltage be. The equipment downstream is unaffected by the overvoltage, the relay takes the full blow.

- contact closed: the MOV is short circuited and the full voltage is present at the downstream equipment, including overvoltage.

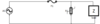

If you want to protect the downstream equipment from overvoltage, the MOV should be across the equipment's power port, the fuse in series:

Here the MOV limits overvoltage and in case of excess current the fuse opens and takes the equipment off the power.