Hi, I need to activate a pump to increase water pressure and would like to use a low cost solution.

I have a pump and I would like to switch it on when there is water flowing.

Once the initial water flux is very low I ordered a water flux meter like this:

https://tse1.mm.bing.net/th?id=OIP.VhTIypYjht52BIUlqKyXsgEsCp&pid=15.1&P=0&w=300&h=300

It is very sensitive and generates pulses as the water goes through it.

Then I need, from those pulses to activate a relay.

As long as there are pulses the relay must remain closed.

No pulses, relay open.

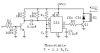

I started trying to use a circuit based on the 555 where a short duration positive pulse generates a pulse on pin 3 that I can control how long it remains active.

So, I thought that as long as new pulses where been fed on pin 2, pin 3 would never go down.

But it is not working like this, pin 3 pulses as well and I read a second pulse on pin 2 does not reset the counter of the timer and pin 3 will inevitably go down and be reactivated on the next pulse on pin 2.

Is there any way I can force the 555 to reset and keep pin 3 on as long as there are pulses on pin 2?

Thanks

I have a pump and I would like to switch it on when there is water flowing.

Once the initial water flux is very low I ordered a water flux meter like this:

https://tse1.mm.bing.net/th?id=OIP.VhTIypYjht52BIUlqKyXsgEsCp&pid=15.1&P=0&w=300&h=300

It is very sensitive and generates pulses as the water goes through it.

Then I need, from those pulses to activate a relay.

As long as there are pulses the relay must remain closed.

No pulses, relay open.

I started trying to use a circuit based on the 555 where a short duration positive pulse generates a pulse on pin 3 that I can control how long it remains active.

So, I thought that as long as new pulses where been fed on pin 2, pin 3 would never go down.

But it is not working like this, pin 3 pulses as well and I read a second pulse on pin 2 does not reset the counter of the timer and pin 3 will inevitably go down and be reactivated on the next pulse on pin 2.

Is there any way I can force the 555 to reset and keep pin 3 on as long as there are pulses on pin 2?

Thanks