Hi guys,

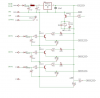

I consider myself a beginner in electronic and i am trying to interface field control boards working in either 24Vac, 24Vdc or 12Vdc (depending on the site) with a 3.3V microcontroller (right Side). After reading a lot on the best way to do it, i came up with the schematic below:

I need your feedback on this design and if there is any way to improve it.

Thank you in advance.

You guys rock.

[mod note -- fixed image]

I consider myself a beginner in electronic and i am trying to interface field control boards working in either 24Vac, 24Vdc or 12Vdc (depending on the site) with a 3.3V microcontroller (right Side). After reading a lot on the best way to do it, i came up with the schematic below:

I need your feedback on this design and if there is any way to improve it.

Thank you in advance.

You guys rock.

[mod note -- fixed image]

Last edited by a moderator: