OK, lots of people ask questions about driving LEDs. So here's a list of common answers and pointers to documentation that is useful.

Here's what I'm covering:

0) Why LEDs are different from light bulbs

0.5) Voltage and current sources

1) Driving a single low power LED

2) Driving a large array of low power LEDs (Including a practical example)

3) Driving a single high power LED <-- Constant current sources are discussed here!

4) Driving an array of high power LEDs

4.5) Chip on Board (COB) LEDs

5) LED Lifetime <-- new

6) Heatsinks

7) Driving LEDs from low voltages

8) Applications

9) Footnotes and additional explanations

A Quick Note

This section will deviate from LEDs a little, but it is important you understand if you want to do more than take this article as a set of recipes. Understanding this will allow you to understand what we're trying to achieve.

The one thing that confuses the most people is that LEDs seem to be described as having some voltage specification, yet we often tell people to ignore the voltage and use a current source.

There are two really important things in the specification of any LED. The first is Vf. This is the approximate voltage across the device when it operates. The second is If. This is the current through the device (typically a nominal operating current).

If a LED was a resistor, the voltage across it would determine the current through it. The equation is: I = V/R. This is called Ohms law and there are other tutorials about it.

From the previous section, you can see that neither lamps nor LEDs are resistances. The voltage Vs current curves would be a straight line if they were.

The important point from the previous section was that driving LEDs from a voltage source is inherently unstable.

So what can we do?

The answer is to turn the world on its head and use a current source.

A current source (if you're not familiar with it) is a very weird thing. In theory it can supply infinite voltages! It increases the voltage until the desired current flows through the load. This may be the first time you've heard of one of these.

So why did I say it turned the world on its head? Well, we can describe a voltage source (think of a battery) as a device that will keep increasing current until a certain voltage appears across a load. Now that is an unusual way of describing a battery. You may have thought of it differently. A theoretical voltage source can supply infinite current. Practical devices (batteries) can't.

Let's think of a perfect 9V voltage source. This will increase the current flowing in a circuit until the voltage across it reaches 9V. (you may have thought of it as a device which supplies 9V).

So now let's think of a 20mA current source. It will increase the voltage until 20mA flows through a load. Say the load is a single red LED. If this is connected to the current source, the voltage will rise until 20mA flows. This may be about 1.7V, but it's not important because the current source will also provide 20mA to a white LED (at maybe 3.4V), or a string of 10 yellow LEDs (20V).

If we have a practical voltage source (a battery) we know that if the load requires too much current, the battery voltage will drop.

A similar issue exists with a current source. If the voltage required is too high, the current will drop.

So, like with a battery, where we have to ensure the load does not draw too much current, but we're not really concerned about the exact current, with a current source we are concerned that it doesn't require too much voltage, but other than that we're not concerned about the exact voltage.

It just so happens that Vf ratings for LEDs are approximate, they vary between devices, and also with temperature and current. BUT the If is something we usually want to set to a certain value. Both of these factors tell us that a current source is the ideal thing to drive a LED.

So if you get told to "forget the voltage across the LED", what we mean is, this is not your primary consideration and it will take care of itself. We will almost always say things like this if we are discussing a real constant current source similar to that described in section 3.

1 - Driving a single low power LED

This is the simplest case, and is often all that people want to do. Even if you want to do something more complex, it's best to understand this first.

I have divided this lecture by talking about high and low power LEDs. In general, a low power LED is one that is rated for 50mA or less, and where the datasheet doesn't talk about the need for heatsinking, and where the LED isn't described using a power (like 0.5W, 3W, or 25W).

Let's assume that we're talking about a white LED that has a current (I) or 20mA at Vf of 3.4V. You will note from an earlier graph that there is a spread of Vf at a given current for LEDs, and that it depends on temperature, but for low power LEDs we can assume that these figures are "close enough".

Let's say we also want to operate this LED from a car battery, nominally 12V, but which can vary from 10.5 to 14 volts.

I have said that a current source is the preferred method of driving a LED. Technically, a voltage source has zero impedance (and a lead acid battery is very close to ideal in this respect as it has a very low internal resistance) and a current source has an infinite impedance (just take my word for this).

With a perfect 20mA current source, a LED will draw exactly 20mA, no matter what the temperature. The voltage across it (Vf) is no longer important.

Perfect current sources, like perfect voltage sources (in fact, perfect anything) do not exist, but we can make something that acts more like a current source than a voltage source by placing a resistor in series with it.

(Image 1.1 from http://www.kpsec.freeuk.com/components/led.htm) This uses Vs and Vl instead of V and Vf, but it's just alternative labelling.

We typically choose a resistor that will limit the current (I) to a chosen value at an assumed Vf. And we have both of these.

R = (V - Vf) / I

In this case, resistance is in ohms, voltage in volts, and current in AMPS (remember that last one because we are normally talking about milliamps)

Using the values we have, R = (12 - 3.4) / 0.025 = 344. In this case we might pick a 330 ohm resistor.

Let's see what the effect of out range of supply voltages is:

I = (V - Vf) / R, for 10.5, 12, and 14 volts, we get: 21.5mA, 26mA, and 32mA

There is a difference in about 50% in the predicted current over the voltage range. This difference (as a percentage) will ALWAYS be larger than the percentage change of voltage.

You would need to check the datasheet to determine if 32mA was acceptable. If it was not, you could either increase the value of the resistor (try the next value, 390 ohms) or regulate the power supply so that it does not vary.

(The graph of Vf vs I in the section above indicates that Vf at 25mA could vary from 3.2 to 3.8V at 25mA. This is a wider spread that you would typically see, but you could plug in the lower Vf into the equation to check what effect this might have. Since the graph is not linear, you can't do a simple calculation to determine the exact effect, but for low power LEDs it's not going to be a huge problem)

There are web sites that will do some of these calculations for you.

There are lots of these on the web, but I've not found any which calculate the effect of fluctuating voltage.

If you don't know what the Vf of your LED is, you may be able to estimate it based on the colour of the LED (See http://www.oksolar.com/led/led_color_chart.htm, or measure it at a much lower current -- by using a 1k resistor and a 9V battery for example)

2 - Driving a large array of low power LEDs

This is the simplest case for high power LEDs. Please ensure you've read at least up to the end of "Driving a single low power LED".

So what is high power? A rough description is anything that is described by power in watts, has a mounting designed for a heatsink, or where the datasheet talks about heatsinks.

The story for driving high power LEDs becomes an issue of thermal management. Using a series resistor to limit current is rarely a viable option (see section 9.1), and some form of active control over current should generally be used.

In almost all cases you'll need to heatsink the LED, so be sure to read the section on heatsinks...

Almost all high power LEDs are rated in terms of the maximum current. From this the Vf might be calculated, but the important issue is current. It could be argued that current should rise as Vf falls in order to maintain the power delivered to the device, but that's not how it's done. (Practically speaking it would be quite difficult to do anyway).

One option is to use a simple constant current circuit like this:

The problem with this circuit is that with a supply voltage of 15 volts, and a single 1W white LED, the circuit will dissipate 4.5 watts (a 1W LED is generally paired with a constant current source of 300mA).

Here is an alternative constant current source built around the LM317.

It suffers from exactly the same issues, but is somewhat better at current regulation.

If you would like an on-line calculator to help you determine the value of R, see here http://diyaudioprojects.com/Technical/Voltage-Regulator/. Please note that it provides the circuit and calculations for both a voltage and a current source. Make sure you use the right one!

A solution to the problem of high power dissipation (especially for high current LEDs) is to use a lower supply rail (but you need sufficient headroom for the constant current source) or to change to a switch-mode constant current source.

An example of a discrete switch-mode current source is shown here:

(Image 3.3 from http://www.simplecircuitdiagram.com/2010/02/13/discrete-high-current-switch-mode-led-driver/)

There are also devices designed specifically for this purpose.

Even if you assume the efficiency of the switch-mode regulator is only 70%, the total power dissipated drops to a little over 1.4W for a 1W LED. That's a saving of over 3W for a 15V supply. When driving high power LEDs from high voltages (think mains) the practical solutions these days are all switch-mode current sources.

The reasons to use switch-mode current sources loom much larger when you have a 12 Watt LED.

Linear constant current sources are worth discussing a little more

The one shown in image 3.1 above is a self contained 2 terminal device. As such, it can be remarkably useful, but some minor changes can make it even more useful.

This incorporates a couple of minor modifications.

The first is that a mosfet is used for Q1 instead of a bipolar transistor. Whilst this requires a larger voltage swing on the gate, it also requires less gate current.

The second is that R2 is not connected to the "top" of Q1.

The third is that the LEDs are "above" the current source rather than "below" it.

This particular arrangement has a couple of advantages and a couple of disadvantages as compared to the one in figure 3.1.

The main advantage is that the voltage drop across Q1 and R1 can be smaller. This allows the circuit to operate from a voltage less than a volt higher than the combined Vf's of the LEDs (the one in figure 3.1 requires in 3V or more). A secondary advantage is that the resistor R2 can be far higher as very little current needs to flow through it.

The main disadvantage is that if the LEDs are disconnected and if the voltage supplied is greater than VGS(max) for Q1, the mosfet will be destroyed.

However, this is a stepping stone to a more useful circuit:

(figure 3.5)

This circuit, if a logic level mosfet is used for Q1, allows a microcontroller to switch a large constant current load. Whilst this could be done with a bipolar transistor for Q1, a mosfet requires far less current to operate.

In both of these cases R1 should be calculated to drop approximately 0.7V at the required LED current, R2 can be very high (47k is fine in most circumstances).

R3 is required for the last circuit to ensure that the LED turns off. It can also be a large value (47k or more would be fine)

4 - Driving an array of high power LEDs

Driving an array of high power LEDs is essentially a similar problem to driving an array of low power LEDs.

The difference is that the constant current source is typically far more expensive that a single resistor. It thus makes sense to use as few constant current sources as possible.

Linear (i.e. not switch-mode) constant current sources have a power dissipation defined by the voltage across them and the current passing through them, so a string of high power LEDs with a linear constant current source will cause less heat to be dissipated in the constant current source than for a single LED.

In contrast, the power dissipated in a switch-mode power supply is proportional to the total power delivered to the load, so the dissipation goes up as the number of LEDs is increased (this is not strictly true in all cases, but is a reasonable rule of thumb).

Because of the near constant voltage characteristic of LEDs, it may be worthwhile considering relatively long strings of LEDs with a linear constant current source.

It is risky to place high power LEDs in parallel for the same reason that it is risky to do so with low power LEDs. Because of the higher powers involved, thermal runaway can occur faster, and it is likely to be rather more expensive.

The alternative to placing LEDs in parallel is to use higher powered LEDs. These are almost certainly manufactured using a series of dies in parallel, but because of their close thermal contact (and presumably because they are closely matched) thermal runaway is far less likely to occur.

4 - Driving an array of high power LEDs

5 - LED Lifetime

LEDs have quoted lifetimes of tens of thousands of hours. Values like 50,000 hours or even 100,000 hours are not uncommonly quoted. Yet it is very common that high power LEDs die well before this, and owners of LED Christmas lights have probably seen the same thing in low powered LEDs.

Why does this happen? Generally it is due to excess current or excess heat.

The lifetime of LEDs is dependant on both the junction temperature and forward current. Reducing either will extend the life of the LED. Since forward current is the main variable in determining junction temperature in any installation, reducing the forward current has a significant effect on life.

This Philips white paper on LED life illustrated the effects of current and temperature of life. The actual figures will not be representative for all LEDs, but the shape of the curves are likely to apply. Note that in some graphs the lifetime is artificially capped at the "rated" life of the device.

When using LED light fittings, it is important to note that LEDs do not radiate IR, so excess heat is almost 100% dissipated by convection and conduction. When a fitting has fins (to assist convective dissipation) it is essential that there is a free flow of air to allow cooling. If these are tightly fitted in a recessed enclosure without ventilation and with insulation overlaying them (as is common when replacing down-lights) then the lifetime will be very severely shortened.

It is important to reiterate though that while heat is a major contributor, the process of actually producing light has a detrimental effect on the LED. So even if you are able to keep the junction at a very low temperature, you will not achieve an infinite lifetime.

6 - Heatsinks

The best rule here is to read the manufacturers information and follow their recommendations. If any changes are to be made, it is best to err on the side of a larger heatsink.

The problem is that some manufacturers provide advice suggesting shortcuts rather than giving safe recommendations.

Further complicating matters is that the maximum junction temperature varies for different colour LEDs (see page 12).

Also note that the lifetime of the LED (typically in the order of 50,000 hours) is based on a junction temperature well below the maximum (90 degrees C being one figure I have seen). Some research clearly illustrates the problem. (This may be more readable). Note that these figures will almost certainly differ for different LEDs.

My best recommendation is to find the thermal resistance of the LED from junction to case (which should be in the specs) and then follow normal heatsink design to choose a heatsink which will keep the junction at a temperature you determine is reasonable.

7 - Driving LEDs from low voltages

If you've read everything above, you'll know that you need at least Vf volts to turn on a LED. And Vf can vary from 1.7V to 3.4V (or even higher for some LED arrays on a chip). So what can you do if you have a lower voltage?

The classic answer to this is the LM3909. If you have a single 1.5V cell (and even a flat one) and you want the minimum parts LED flasher, then this will do it for you. These days they're becoming a little hard to get, but it's hard to go past simplicity. This site has a pretty goof description of its operation. There are a number of modern devices that provide related functionality.

There are several theoretical approaches to this problem they are:

The last 2 are very similar.

The LM3909 is a switched capacitor device. LED garden lights also often use this technique. Basically a capacitor is charged up using the low voltage, then it is placed in series with the battery to boost (almost doubling) the voltage. Also called "charge pumps", these are quite often used to power white LEDs from low voltages.

A boost SMPS employs an inductor to store power, which is then effectively placed in series with the incoming voltage. There are a number of schematics for these on the web.

The third option is to create an AC voltage which is stepped up by a transformer and then rectified. (Some SMPS's operate like this too). This option is often used when you want a much higher voltage. Operating a camera flash (requires around 300V) from a 1.5V battery is one application of these. However for lower voltages (as are typically used by LEDs) the additional bulk of the transformer is a big negative.

Generally you will use one of the first two options. Here is a discussion of the pros and cons of each method.

Current limiting in these circuits is not simple or obvious, but is still just as important as when you are driving a LED from a higher voltage.

8 - Applications

This section is really nothing but a list of applications and circuits that have a lot to do with LEDs.

Many people want to do more than simply "drive a LED", so this section may provide some pointers to help you achieve some greater objective.

These sites have their own list of LED circuits

9 - Footnotes and additional explanations.

Here's what I'm covering:

0) Why LEDs are different from light bulbs

0.5) Voltage and current sources

1) Driving a single low power LED

2) Driving a large array of low power LEDs (Including a practical example)

3) Driving a single high power LED <-- Constant current sources are discussed here!

4) Driving an array of high power LEDs

4.5) Chip on Board (COB) LEDs

5) LED Lifetime <-- new

6) Heatsinks

7) Driving LEDs from low voltages

8) Applications

9) Footnotes and additional explanations

A Quick Note

You may have been directed here after asking a question about LEDs. We're not trying to be rude, but we get a LOT of questions about this and we have tried to answer as many of them as possible in this post.

If you find the answer in here, then you have probably managed to get it more quickly than if you had to wait for someone to post an answer.

If you don't find the answer here, or you don't understand what you feel may be the answer, or if you just want more details, then go back to your original thread (where you may have been directed here) and post a follow-up question. Tell us what you don't understand, or where you want more detail.

We don't expect that this thread is suitable for people of all skills, nor does it try to be exhaustive as to the options you may have.

With your use and feedback, we will try to keep improving this post.

0 - Why LEDs are different from light bulbsIf you find the answer in here, then you have probably managed to get it more quickly than if you had to wait for someone to post an answer.

If you don't find the answer here, or you don't understand what you feel may be the answer, or if you just want more details, then go back to your original thread (where you may have been directed here) and post a follow-up question. Tell us what you don't understand, or where you want more detail.

We don't expect that this thread is suitable for people of all skills, nor does it try to be exhaustive as to the options you may have.

With your use and feedback, we will try to keep improving this post.

If you're not familiar with LEDs, read this because I'll be covering some background material here that I'm not going to repeat in each section

The first thing to understand is that LEDs and light bulbs are not interchangeable. If you think of them as chalk and cheese, you'll have some idea of how different they are.

The most fundamental difference is that you have to connect a LED up the right way around. LEDs can be damaged by relatively low reverse voltages, so this is important.

Here is a diagram showing how to determine which way many small LEDs are connected.

(Image 0.1)

Note that there are three indications, the anode (+ve) lead is longer, the cathode (-ve) lead is next to a flat in the side of the LED, and looking through the LED, the larger electrode with the flat top is usually the cathode (-ve).

If in doubt, a 4.5 to 6V DC supply in series with a 220 ohm to 1k ohm resistor can be safely used to determine which lead is which.

A normal incandescent light bulb uses the current to heat a filament which glows, emitting light. As it gets hotter its resistance increases. Such bulbs have a voltage rating and you can operate them at any voltage up to the rated voltage. At lower voltages the light gets redder. At a safe voltage the bulb will happily sit there attached to a battery (or other power supply) and work for a long time.

The diagram below shows the relationship between voltage and current for a lamp:

Because the resistance of the filament increases with temperature, a bulb naturally remains in equilibrium. As the ambient temperature increases (or the lamp gets hotter for some reason) the resistance increases, forcing a lower current (which tends to cool the bulb) The bulb will also continue to operate over a wide range of temperatures.

Slight fluctuations in voltage have an effect on the current, but it is less than proportional. Whilst a large overvoltage may cause increased power dissipation in the filament resulting its failure, the tendency for the system to remain in equilibrium means that the bulb is actually very rugged and also requires little protection from short, moderate transients.

A LED is very different. It is essentially a diode. A diode does not behave like a resistor. As the voltage across a diode increases the current through it increases much faster. The diagram below illustrates the issue:

Note that in the diagram above, the "three random LEDs" will all be the same type, possibly from different batches. The illustration shows that there is variation within a type of LED, and variation between different types of LEDs.

A LED nominally rated at 3.4 volts (presumably at 20mA) may actually draw a far higher (or lower) current. Notice that a slight increase in voltage will result in a relatively much larger increase in current.

Compounding this is another problem. As the LED gets hotter, the forward voltage at a given current falls.

Putting these two things together means that a LED operated from a constant voltage (initially carefully chosen to give a safe current) will suffer from a condition known as thermal runaway.

The LED is presumably at room temperature when you make your initial measurements. As you turn it on, the LED heats up (initially very slowly). This heating is caused because less than 100% of the power is converted to light. That slight temperature rise causes the forward voltage (Vf) at a particular current to fall. This means that for the same Vf the current (I) is larger. Due to the higher current, the amount of power dissipated in the LED is greater and the temperature rises a little more. This leads to a further increase in I to maintain the Vf. This process accelerates, and eventually the temperature of the junction exceeds the maximum and the LED stops working.

If the voltage source is not completely stable, the problems get far worse. A slight decrease will case a (relatively safe) drastic reduction in current and therefore brightness. A slight increase will cause a (potentially destructive) increase in current and therefore brightness. If the LED wasn't already rapidly heading for destruction, it is likely to be well on its way now...

This is not something that may happen, it is something that WILL happen. If the current or duty cycle is low, it may take longer to happen, but you can guarantee that the life of the LED will be shorter that it would otherwise be. Instead of 50,000 hours, you might get 1000 hours, or 100, or 10, or three minutes, or a few seconds.

LEDs are inherently unstable when operated from a voltage source. The answer is to operate them from a current source as the manufacturers intend.

Now, we're all familiar with voltage sources, but current sources are something quite odd at first. Luckily, we can often get away with something that is less than a true current source, but good enough to make the LED stable. And I'll be covering the simplest case next...

0.5 - Voltage and current sourcesThe first thing to understand is that LEDs and light bulbs are not interchangeable. If you think of them as chalk and cheese, you'll have some idea of how different they are.

The most fundamental difference is that you have to connect a LED up the right way around. LEDs can be damaged by relatively low reverse voltages, so this is important.

Here is a diagram showing how to determine which way many small LEDs are connected.

(Image 0.1)

Note that there are three indications, the anode (+ve) lead is longer, the cathode (-ve) lead is next to a flat in the side of the LED, and looking through the LED, the larger electrode with the flat top is usually the cathode (-ve).

If in doubt, a 4.5 to 6V DC supply in series with a 220 ohm to 1k ohm resistor can be safely used to determine which lead is which.

A normal incandescent light bulb uses the current to heat a filament which glows, emitting light. As it gets hotter its resistance increases. Such bulbs have a voltage rating and you can operate them at any voltage up to the rated voltage. At lower voltages the light gets redder. At a safe voltage the bulb will happily sit there attached to a battery (or other power supply) and work for a long time.

The diagram below shows the relationship between voltage and current for a lamp:

Because the resistance of the filament increases with temperature, a bulb naturally remains in equilibrium. As the ambient temperature increases (or the lamp gets hotter for some reason) the resistance increases, forcing a lower current (which tends to cool the bulb) The bulb will also continue to operate over a wide range of temperatures.

Slight fluctuations in voltage have an effect on the current, but it is less than proportional. Whilst a large overvoltage may cause increased power dissipation in the filament resulting its failure, the tendency for the system to remain in equilibrium means that the bulb is actually very rugged and also requires little protection from short, moderate transients.

A LED is very different. It is essentially a diode. A diode does not behave like a resistor. As the voltage across a diode increases the current through it increases much faster. The diagram below illustrates the issue:

Note that in the diagram above, the "three random LEDs" will all be the same type, possibly from different batches. The illustration shows that there is variation within a type of LED, and variation between different types of LEDs.

A LED nominally rated at 3.4 volts (presumably at 20mA) may actually draw a far higher (or lower) current. Notice that a slight increase in voltage will result in a relatively much larger increase in current.

Compounding this is another problem. As the LED gets hotter, the forward voltage at a given current falls.

Putting these two things together means that a LED operated from a constant voltage (initially carefully chosen to give a safe current) will suffer from a condition known as thermal runaway.

The LED is presumably at room temperature when you make your initial measurements. As you turn it on, the LED heats up (initially very slowly). This heating is caused because less than 100% of the power is converted to light. That slight temperature rise causes the forward voltage (Vf) at a particular current to fall. This means that for the same Vf the current (I) is larger. Due to the higher current, the amount of power dissipated in the LED is greater and the temperature rises a little more. This leads to a further increase in I to maintain the Vf. This process accelerates, and eventually the temperature of the junction exceeds the maximum and the LED stops working.

If the voltage source is not completely stable, the problems get far worse. A slight decrease will case a (relatively safe) drastic reduction in current and therefore brightness. A slight increase will cause a (potentially destructive) increase in current and therefore brightness. If the LED wasn't already rapidly heading for destruction, it is likely to be well on its way now...

This is not something that may happen, it is something that WILL happen. If the current or duty cycle is low, it may take longer to happen, but you can guarantee that the life of the LED will be shorter that it would otherwise be. Instead of 50,000 hours, you might get 1000 hours, or 100, or 10, or three minutes, or a few seconds.

LEDs are inherently unstable when operated from a voltage source. The answer is to operate them from a current source as the manufacturers intend.

Now, we're all familiar with voltage sources, but current sources are something quite odd at first. Luckily, we can often get away with something that is less than a true current source, but good enough to make the LED stable. And I'll be covering the simplest case next...

This section will deviate from LEDs a little, but it is important you understand if you want to do more than take this article as a set of recipes. Understanding this will allow you to understand what we're trying to achieve.

The one thing that confuses the most people is that LEDs seem to be described as having some voltage specification, yet we often tell people to ignore the voltage and use a current source.

There are two really important things in the specification of any LED. The first is Vf. This is the approximate voltage across the device when it operates. The second is If. This is the current through the device (typically a nominal operating current).

If a LED was a resistor, the voltage across it would determine the current through it. The equation is: I = V/R. This is called Ohms law and there are other tutorials about it.

From the previous section, you can see that neither lamps nor LEDs are resistances. The voltage Vs current curves would be a straight line if they were.

The important point from the previous section was that driving LEDs from a voltage source is inherently unstable.

So what can we do?

The answer is to turn the world on its head and use a current source.

A current source (if you're not familiar with it) is a very weird thing. In theory it can supply infinite voltages! It increases the voltage until the desired current flows through the load. This may be the first time you've heard of one of these.

So why did I say it turned the world on its head? Well, we can describe a voltage source (think of a battery) as a device that will keep increasing current until a certain voltage appears across a load. Now that is an unusual way of describing a battery. You may have thought of it differently. A theoretical voltage source can supply infinite current. Practical devices (batteries) can't.

Let's think of a perfect 9V voltage source. This will increase the current flowing in a circuit until the voltage across it reaches 9V. (you may have thought of it as a device which supplies 9V).

So now let's think of a 20mA current source. It will increase the voltage until 20mA flows through a load. Say the load is a single red LED. If this is connected to the current source, the voltage will rise until 20mA flows. This may be about 1.7V, but it's not important because the current source will also provide 20mA to a white LED (at maybe 3.4V), or a string of 10 yellow LEDs (20V).

If we have a practical voltage source (a battery) we know that if the load requires too much current, the battery voltage will drop.

A similar issue exists with a current source. If the voltage required is too high, the current will drop.

So, like with a battery, where we have to ensure the load does not draw too much current, but we're not really concerned about the exact current, with a current source we are concerned that it doesn't require too much voltage, but other than that we're not concerned about the exact voltage.

It just so happens that Vf ratings for LEDs are approximate, they vary between devices, and also with temperature and current. BUT the If is something we usually want to set to a certain value. Both of these factors tell us that a current source is the ideal thing to drive a LED.

So if you get told to "forget the voltage across the LED", what we mean is, this is not your primary consideration and it will take care of itself. We will almost always say things like this if we are discussing a real constant current source similar to that described in section 3.

This is the simplest case, and is often all that people want to do. Even if you want to do something more complex, it's best to understand this first.

I have divided this lecture by talking about high and low power LEDs. In general, a low power LED is one that is rated for 50mA or less, and where the datasheet doesn't talk about the need for heatsinking, and where the LED isn't described using a power (like 0.5W, 3W, or 25W).

Let's assume that we're talking about a white LED that has a current (I) or 20mA at Vf of 3.4V. You will note from an earlier graph that there is a spread of Vf at a given current for LEDs, and that it depends on temperature, but for low power LEDs we can assume that these figures are "close enough".

Let's say we also want to operate this LED from a car battery, nominally 12V, but which can vary from 10.5 to 14 volts.

I have said that a current source is the preferred method of driving a LED. Technically, a voltage source has zero impedance (and a lead acid battery is very close to ideal in this respect as it has a very low internal resistance) and a current source has an infinite impedance (just take my word for this).

With a perfect 20mA current source, a LED will draw exactly 20mA, no matter what the temperature. The voltage across it (Vf) is no longer important.

Perfect current sources, like perfect voltage sources (in fact, perfect anything) do not exist, but we can make something that acts more like a current source than a voltage source by placing a resistor in series with it.

(Image 1.1 from http://www.kpsec.freeuk.com/components/led.htm) This uses Vs and Vl instead of V and Vf, but it's just alternative labelling.

We typically choose a resistor that will limit the current (I) to a chosen value at an assumed Vf. And we have both of these.

R = (V - Vf) / I

In this case, resistance is in ohms, voltage in volts, and current in AMPS (remember that last one because we are normally talking about milliamps)

Using the values we have, R = (12 - 3.4) / 0.025 = 344. In this case we might pick a 330 ohm resistor.

Let's see what the effect of out range of supply voltages is:

I = (V - Vf) / R, for 10.5, 12, and 14 volts, we get: 21.5mA, 26mA, and 32mA

There is a difference in about 50% in the predicted current over the voltage range. This difference (as a percentage) will ALWAYS be larger than the percentage change of voltage.

You would need to check the datasheet to determine if 32mA was acceptable. If it was not, you could either increase the value of the resistor (try the next value, 390 ohms) or regulate the power supply so that it does not vary.

(The graph of Vf vs I in the section above indicates that Vf at 25mA could vary from 3.2 to 3.8V at 25mA. This is a wider spread that you would typically see, but you could plug in the lower Vf into the equation to check what effect this might have. Since the graph is not linear, you can't do a simple calculation to determine the exact effect, but for low power LEDs it's not going to be a huge problem)

There are web sites that will do some of these calculations for you.

- http://led.linear1.org/1led.wiz (simple, but does not calculate effect of different voltages)

- http://www.csgnetwork.com/ledsingresistancecalc.html (calculates next preferred value and power dissipated)

- http://home.cogeco.ca/~rpaisley4/LEDcalc.html (Also does multiple LEDs)

There are lots of these on the web, but I've not found any which calculate the effect of fluctuating voltage.

If you don't know what the Vf of your LED is, you may be able to estimate it based on the colour of the LED (See http://www.oksolar.com/led/led_color_chart.htm, or measure it at a much lower current -- by using a 1k resistor and a 9V battery for example)

This is really the most common thing we get asked about. Amperage of 200 LEDs? (No, I'm not picking on this person -- it's a common question and this poster was the one who inspired me to write this. Hopefully he is going to help a lot of people.)

There are many ways to wire up an array of LEDs. I will only be considering those that involve a simple DC power supply.

The first method is to do exactly what you would have done to power one low powered LED, but do it over and over again.

This is simple, and since all the LEDs are in parallel, we can just multiply the current drawn by each LED and multiply it by the number of LEDs. So 10 LEDs operating at 25mA would require a power supply capable of supplying 250mA.

The second method is a short cut that people think should do the same thing:

Don't do this.

This can lead to thermal runaway. The reason is that the LEDs will not be perfectly matched and will have slightly different Vf for a particular current. Since they are all operating at the same voltage now, the current through them will vary. The ones that get slightly more current will heat up faster than those getting slightly less current. This will cause those getting more current to draw more current, increasing the imbalance until either one LED is hogging almost all the current or a LED fails. As one LED fails, the others quickly fail...

However, you will note that this layout IS used on some high power LEDs. Whilst we're getting a bit ahead of ourselves here, this works because the individual dies are both well matched, but also (and most importantly) thermally coupled. This means that one LED getting hotter will heat the other one too. They tend to continue to share current quite well.

The third method is to put multiple LEDs in series.

I call this a string of LEDs. Because they are in series, each LED has the same current passing through it. So three LEDs operating at 25mA require just 25mA in total. The drawback is that the Vf for all diodes must be added up and must be less than the supply voltage.

The advantage of this is that for a given power supply voltage, less current is required. This means less heat is dissipated by resistors because that's where the extra power goes).

The disadvantage is that fluctuations in voltage cause a significantly higher variation in LED current.

Let''s repeat the example in the preceding section, but for three LEDs.

Essentially the only change is that Vf is now 3 x 3.4, or 10.2V

We choose a resistor that will limit the current (I) to a chosen value at an assumed Vf. And we have both of these.

R = (V - Vf) / I

In this case, resistance is in ohms, voltage in volts, and current in AMPS (remember that last one because we are normally talking about milliamps)

Using the values we have, R = (12 - 10.2) / 0.025 = 72. In this case we might pick a 82 ohm resistor.

Let's see what the effect of out range of supply voltages is:

I = (V - Vf) / R, for 10.5, 12, and 14 volts, we get: 3.7mA, 22mA, and 46mA

There is a difference of over 1000% in the predicted current over the voltage range. This range would be excessive, and at the high end may be close to damaging the LEDs (whilst at the low end would be extremely dim).

If the 12V source was well regulated (say to within a few tenths of a volt) then it would be quite acceptable.

The fourth method is to put multiple strings in parallel.

This is really like the first method, but using the technique employed in the third method to get several LEDs sharing current.

Here is a page that will calculate how to connect LEDs in this manner. It even shows you a circuit diagram, and figures out how many diodes to put in each string.

One thing you need to note though. If the calculation yields a very low value resistor (say less than 100 ohms) then you should carefully consider whether this is appropriate. Calculate the voltage across that resistor and ensure that any variation of your power supply is small (preferably less than 25% of) this voltage drop.

If you are interested in a more technical discussion of why this particular method of connecting LEDs is recommended, see here (pdf from Osram).

PRACTICAL EXAMPLE

In another thread, the question was asked about wiring up a large string of red and blue LEDs. These were to be run from an unspecified voltage source (either 12 or 24 volts). The suggestion was:

3 - Driving a single high power LEDThere are many ways to wire up an array of LEDs. I will only be considering those that involve a simple DC power supply.

The first method is to do exactly what you would have done to power one low powered LED, but do it over and over again.

This is simple, and since all the LEDs are in parallel, we can just multiply the current drawn by each LED and multiply it by the number of LEDs. So 10 LEDs operating at 25mA would require a power supply capable of supplying 250mA.

The second method is a short cut that people think should do the same thing:

Don't do this.

This can lead to thermal runaway. The reason is that the LEDs will not be perfectly matched and will have slightly different Vf for a particular current. Since they are all operating at the same voltage now, the current through them will vary. The ones that get slightly more current will heat up faster than those getting slightly less current. This will cause those getting more current to draw more current, increasing the imbalance until either one LED is hogging almost all the current or a LED fails. As one LED fails, the others quickly fail...

However, you will note that this layout IS used on some high power LEDs. Whilst we're getting a bit ahead of ourselves here, this works because the individual dies are both well matched, but also (and most importantly) thermally coupled. This means that one LED getting hotter will heat the other one too. They tend to continue to share current quite well.

The third method is to put multiple LEDs in series.

I call this a string of LEDs. Because they are in series, each LED has the same current passing through it. So three LEDs operating at 25mA require just 25mA in total. The drawback is that the Vf for all diodes must be added up and must be less than the supply voltage.

The advantage of this is that for a given power supply voltage, less current is required. This means less heat is dissipated by resistors because that's where the extra power goes).

The disadvantage is that fluctuations in voltage cause a significantly higher variation in LED current.

Let''s repeat the example in the preceding section, but for three LEDs.

Essentially the only change is that Vf is now 3 x 3.4, or 10.2V

We choose a resistor that will limit the current (I) to a chosen value at an assumed Vf. And we have both of these.

R = (V - Vf) / I

In this case, resistance is in ohms, voltage in volts, and current in AMPS (remember that last one because we are normally talking about milliamps)

Using the values we have, R = (12 - 10.2) / 0.025 = 72. In this case we might pick a 82 ohm resistor.

Let's see what the effect of out range of supply voltages is:

I = (V - Vf) / R, for 10.5, 12, and 14 volts, we get: 3.7mA, 22mA, and 46mA

There is a difference of over 1000% in the predicted current over the voltage range. This range would be excessive, and at the high end may be close to damaging the LEDs (whilst at the low end would be extremely dim).

If the 12V source was well regulated (say to within a few tenths of a volt) then it would be quite acceptable.

The fourth method is to put multiple strings in parallel.

This is really like the first method, but using the technique employed in the third method to get several LEDs sharing current.

Here is a page that will calculate how to connect LEDs in this manner. It even shows you a circuit diagram, and figures out how many diodes to put in each string.

One thing you need to note though. If the calculation yields a very low value resistor (say less than 100 ohms) then you should carefully consider whether this is appropriate. Calculate the voltage across that resistor and ensure that any variation of your power supply is small (preferably less than 25% of) this voltage drop.

If you are interested in a more technical discussion of why this particular method of connecting LEDs is recommended, see here (pdf from Osram).

PRACTICAL EXAMPLE

In another thread, the question was asked about wiring up a large string of red and blue LEDs. These were to be run from an unspecified voltage source (either 12 or 24 volts). The suggestion was:

There are a number of things you need to know:

1) the forward voltage of your LEDs. This will usually be specified as something like Vf@20mA in the LED specs and may be a range of voltages. Take the typical value or mid-way between the min and max.

This will differ between different types of LEDs, but mostly between colours.

2) your supply voltage you said 12V or 24V, but it is wise to know the range of voltages which may be present. For example, a car battery may vary from 10V to 14V. Larger variation will make things harder and will also reduce the number of LEDs you can place in a string.

Then go here

As your source voltage, enter your MINIMUM input voltage (say 10V).

As the diode forward voltage, enter the number you got from the specs.

As the diode forward current enter 20 (20 mA) or whatever current you want to run them from.

for the number of LEDs in the array, enter a large number, say 100.

Then click "design my array"

You will see a diagram showing a number of strings of LEDs and a resistor all connected in parallel. Note the number of LEDs in each string, and the value of the resistor.

Now go back to your input fields.

Change the input voltage to the maximum voltage your power supply will deliver.

Change the number of LEDs in the array to the number placed in each string previously.

Now hit "design my array" again.

Note the new value of the resistor -- this is the value you should use.

You will need to do this for each type of LED you have. Possibly only twice if you have red and blue LEDs which are all the same. Possibly more often if you have LEDs from a whole heap of different manufacturers.

The problem with using a single resistor like this is that the brightness will fall off quite rapidly with voltage. If your voltage source is stable (i.e. the min and max voltages are very close) then you will have fewer problems.

After you've done this you will have to wire up the LEDs in many strings and connect them all up.

I hope that's clearer.

Whether or not you get enough light at 20mA is another issue. Perhaps you should check the specs to see what the maximum continuous current is. It may be 25 or 30 mA (or even more) and you would be wise to use the max value as stated in the specifications.

If you don't have any specifications, you need to find another source of LEDs that can provide them. If you've already bought them, you could measure the Vf by estimating the Vf and calculating a resistor which will limit the current correctly, then measuring Vf to verify.

1) the forward voltage of your LEDs. This will usually be specified as something like Vf@20mA in the LED specs and may be a range of voltages. Take the typical value or mid-way between the min and max.

This will differ between different types of LEDs, but mostly between colours.

2) your supply voltage you said 12V or 24V, but it is wise to know the range of voltages which may be present. For example, a car battery may vary from 10V to 14V. Larger variation will make things harder and will also reduce the number of LEDs you can place in a string.

Then go here

As your source voltage, enter your MINIMUM input voltage (say 10V).

As the diode forward voltage, enter the number you got from the specs.

As the diode forward current enter 20 (20 mA) or whatever current you want to run them from.

for the number of LEDs in the array, enter a large number, say 100.

Then click "design my array"

You will see a diagram showing a number of strings of LEDs and a resistor all connected in parallel. Note the number of LEDs in each string, and the value of the resistor.

Now go back to your input fields.

Change the input voltage to the maximum voltage your power supply will deliver.

Change the number of LEDs in the array to the number placed in each string previously.

Now hit "design my array" again.

Note the new value of the resistor -- this is the value you should use.

You will need to do this for each type of LED you have. Possibly only twice if you have red and blue LEDs which are all the same. Possibly more often if you have LEDs from a whole heap of different manufacturers.

The problem with using a single resistor like this is that the brightness will fall off quite rapidly with voltage. If your voltage source is stable (i.e. the min and max voltages are very close) then you will have fewer problems.

After you've done this you will have to wire up the LEDs in many strings and connect them all up.

I hope that's clearer.

Whether or not you get enough light at 20mA is another issue. Perhaps you should check the specs to see what the maximum continuous current is. It may be 25 or 30 mA (or even more) and you would be wise to use the max value as stated in the specifications.

If you don't have any specifications, you need to find another source of LEDs that can provide them. If you've already bought them, you could measure the Vf by estimating the Vf and calculating a resistor which will limit the current correctly, then measuring Vf to verify.

This is the simplest case for high power LEDs. Please ensure you've read at least up to the end of "Driving a single low power LED".

So what is high power? A rough description is anything that is described by power in watts, has a mounting designed for a heatsink, or where the datasheet talks about heatsinks.

The story for driving high power LEDs becomes an issue of thermal management. Using a series resistor to limit current is rarely a viable option (see section 9.1), and some form of active control over current should generally be used.

In almost all cases you'll need to heatsink the LED, so be sure to read the section on heatsinks...

Almost all high power LEDs are rated in terms of the maximum current. From this the Vf might be calculated, but the important issue is current. It could be argued that current should rise as Vf falls in order to maintain the power delivered to the device, but that's not how it's done. (Practically speaking it would be quite difficult to do anyway).

One option is to use a simple constant current circuit like this:

The problem with this circuit is that with a supply voltage of 15 volts, and a single 1W white LED, the circuit will dissipate 4.5 watts (a 1W LED is generally paired with a constant current source of 300mA).

Here is an alternative constant current source built around the LM317.

It suffers from exactly the same issues, but is somewhat better at current regulation.

If you would like an on-line calculator to help you determine the value of R, see here http://diyaudioprojects.com/Technical/Voltage-Regulator/. Please note that it provides the circuit and calculations for both a voltage and a current source. Make sure you use the right one!

A solution to the problem of high power dissipation (especially for high current LEDs) is to use a lower supply rail (but you need sufficient headroom for the constant current source) or to change to a switch-mode constant current source.

An example of a discrete switch-mode current source is shown here:

(Image 3.3 from http://www.simplecircuitdiagram.com/2010/02/13/discrete-high-current-switch-mode-led-driver/)

There are also devices designed specifically for this purpose.

Even if you assume the efficiency of the switch-mode regulator is only 70%, the total power dissipated drops to a little over 1.4W for a 1W LED. That's a saving of over 3W for a 15V supply. When driving high power LEDs from high voltages (think mains) the practical solutions these days are all switch-mode current sources.

The reasons to use switch-mode current sources loom much larger when you have a 12 Watt LED.

Linear constant current sources are worth discussing a little more

The one shown in image 3.1 above is a self contained 2 terminal device. As such, it can be remarkably useful, but some minor changes can make it even more useful.

This incorporates a couple of minor modifications.

The first is that a mosfet is used for Q1 instead of a bipolar transistor. Whilst this requires a larger voltage swing on the gate, it also requires less gate current.

The second is that R2 is not connected to the "top" of Q1.

The third is that the LEDs are "above" the current source rather than "below" it.

This particular arrangement has a couple of advantages and a couple of disadvantages as compared to the one in figure 3.1.

The main advantage is that the voltage drop across Q1 and R1 can be smaller. This allows the circuit to operate from a voltage less than a volt higher than the combined Vf's of the LEDs (the one in figure 3.1 requires in 3V or more). A secondary advantage is that the resistor R2 can be far higher as very little current needs to flow through it.

The main disadvantage is that if the LEDs are disconnected and if the voltage supplied is greater than VGS(max) for Q1, the mosfet will be destroyed.

However, this is a stepping stone to a more useful circuit:

(figure 3.5)

This circuit, if a logic level mosfet is used for Q1, allows a microcontroller to switch a large constant current load. Whilst this could be done with a bipolar transistor for Q1, a mosfet requires far less current to operate.

In both of these cases R1 should be calculated to drop approximately 0.7V at the required LED current, R2 can be very high (47k is fine in most circumstances).

R3 is required for the last circuit to ensure that the LED turns off. It can also be a large value (47k or more would be fine)

Driving an array of high power LEDs is essentially a similar problem to driving an array of low power LEDs.

The difference is that the constant current source is typically far more expensive that a single resistor. It thus makes sense to use as few constant current sources as possible.

Linear (i.e. not switch-mode) constant current sources have a power dissipation defined by the voltage across them and the current passing through them, so a string of high power LEDs with a linear constant current source will cause less heat to be dissipated in the constant current source than for a single LED.

In contrast, the power dissipated in a switch-mode power supply is proportional to the total power delivered to the load, so the dissipation goes up as the number of LEDs is increased (this is not strictly true in all cases, but is a reasonable rule of thumb).

Because of the near constant voltage characteristic of LEDs, it may be worthwhile considering relatively long strings of LEDs with a linear constant current source.

It is risky to place high power LEDs in parallel for the same reason that it is risky to do so with low power LEDs. Because of the higher powers involved, thermal runaway can occur faster, and it is likely to be rather more expensive.

The alternative to placing LEDs in parallel is to use higher powered LEDs. These are almost certainly manufactured using a series of dies in parallel, but because of their close thermal contact (and presumably because they are closely matched) thermal runaway is far less likely to occur.

You may have seen or head about COB LEDs. These are modules which have an array of individual LEDs bonded onto a common heatsink. They look like very large, flat LEDs. They normally have metal pads or tabs rather than leads.

Note that COB LEDs are wired as an array of strings of LEDs in parallel. Previously, this resource has indicated that this is a poor way to wire up LEDs. In this case however, the LEDs are (or should be) closely matched and in close thermal contact. This limits the degree to which thermal runaway can occur in a single LED or string, maintaining a balance in the currents through the parallel strings.

Because of the construction, the Vf of COB LEDs is typically quite large. They can range from 12V to 36V, or higher.

At low currents (say a few tens of mA or less) you can see the individual elements. You should see all of he individual elements illuminate at the same brightness.

In the example above, all 50 individual LEDs can be seen to illuminate, and the brightness appears equal. Note that this is a 50W COB LED. Typically the individual LEDs are rated at about 1W.

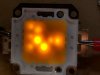

Many COB LEDs are available very cheaply. Often these are faulty. In the example above, it is clear that not all individual LEDs are lit, and those which are are clearly NOT at the same brightness. This module would not be able to be used at it's rated power, and would probably fail fairly quickly. If you receive a COB LED module that lights up like this, demand a refund!

COB LEDs are like other high power LEDs in most respects:

Note that COB LEDs are wired as an array of strings of LEDs in parallel. Previously, this resource has indicated that this is a poor way to wire up LEDs. In this case however, the LEDs are (or should be) closely matched and in close thermal contact. This limits the degree to which thermal runaway can occur in a single LED or string, maintaining a balance in the currents through the parallel strings.

Because of the construction, the Vf of COB LEDs is typically quite large. They can range from 12V to 36V, or higher.

At low currents (say a few tens of mA or less) you can see the individual elements. You should see all of he individual elements illuminate at the same brightness.

In the example above, all 50 individual LEDs can be seen to illuminate, and the brightness appears equal. Note that this is a 50W COB LED. Typically the individual LEDs are rated at about 1W.

Many COB LEDs are available very cheaply. Often these are faulty. In the example above, it is clear that not all individual LEDs are lit, and those which are are clearly NOT at the same brightness. This module would not be able to be used at it's rated power, and would probably fail fairly quickly. If you receive a COB LED module that lights up like this, demand a refund!

COB LEDs are like other high power LEDs in most respects:

- They have a high Vf.

- They should be driven from a current source

- They should not be operated at significant power levels without a heatsink.

5 - LED Lifetime

LEDs have quoted lifetimes of tens of thousands of hours. Values like 50,000 hours or even 100,000 hours are not uncommonly quoted. Yet it is very common that high power LEDs die well before this, and owners of LED Christmas lights have probably seen the same thing in low powered LEDs.

Why does this happen? Generally it is due to excess current or excess heat.

The lifetime of LEDs is dependant on both the junction temperature and forward current. Reducing either will extend the life of the LED. Since forward current is the main variable in determining junction temperature in any installation, reducing the forward current has a significant effect on life.

This Philips white paper on LED life illustrated the effects of current and temperature of life. The actual figures will not be representative for all LEDs, but the shape of the curves are likely to apply. Note that in some graphs the lifetime is artificially capped at the "rated" life of the device.

When using LED light fittings, it is important to note that LEDs do not radiate IR, so excess heat is almost 100% dissipated by convection and conduction. When a fitting has fins (to assist convective dissipation) it is essential that there is a free flow of air to allow cooling. If these are tightly fitted in a recessed enclosure without ventilation and with insulation overlaying them (as is common when replacing down-lights) then the lifetime will be very severely shortened.

It is important to reiterate though that while heat is a major contributor, the process of actually producing light has a detrimental effect on the LED. So even if you are able to keep the junction at a very low temperature, you will not achieve an infinite lifetime.

The best rule here is to read the manufacturers information and follow their recommendations. If any changes are to be made, it is best to err on the side of a larger heatsink.

The problem is that some manufacturers provide advice suggesting shortcuts rather than giving safe recommendations.

Further complicating matters is that the maximum junction temperature varies for different colour LEDs (see page 12).

Also note that the lifetime of the LED (typically in the order of 50,000 hours) is based on a junction temperature well below the maximum (90 degrees C being one figure I have seen). Some research clearly illustrates the problem. (This may be more readable). Note that these figures will almost certainly differ for different LEDs.

My best recommendation is to find the thermal resistance of the LED from junction to case (which should be in the specs) and then follow normal heatsink design to choose a heatsink which will keep the junction at a temperature you determine is reasonable.

If you've read everything above, you'll know that you need at least Vf volts to turn on a LED. And Vf can vary from 1.7V to 3.4V (or even higher for some LED arrays on a chip). So what can you do if you have a lower voltage?

The classic answer to this is the LM3909. If you have a single 1.5V cell (and even a flat one) and you want the minimum parts LED flasher, then this will do it for you. These days they're becoming a little hard to get, but it's hard to go past simplicity. This site has a pretty goof description of its operation. There are a number of modern devices that provide related functionality.

There are several theoretical approaches to this problem they are:

- Switched capacitor.

- Boost SMPS

- Oscillator with transformer

The last 2 are very similar.

The LM3909 is a switched capacitor device. LED garden lights also often use this technique. Basically a capacitor is charged up using the low voltage, then it is placed in series with the battery to boost (almost doubling) the voltage. Also called "charge pumps", these are quite often used to power white LEDs from low voltages.

A boost SMPS employs an inductor to store power, which is then effectively placed in series with the incoming voltage. There are a number of schematics for these on the web.

The third option is to create an AC voltage which is stepped up by a transformer and then rectified. (Some SMPS's operate like this too). This option is often used when you want a much higher voltage. Operating a camera flash (requires around 300V) from a 1.5V battery is one application of these. However for lower voltages (as are typically used by LEDs) the additional bulk of the transformer is a big negative.

Generally you will use one of the first two options. Here is a discussion of the pros and cons of each method.

Current limiting in these circuits is not simple or obvious, but is still just as important as when you are driving a LED from a higher voltage.

This section is really nothing but a list of applications and circuits that have a lot to do with LEDs.

Many people want to do more than simply "drive a LED", so this section may provide some pointers to help you achieve some greater objective.

- http://www.bowdenshobbycircuits.info/page5.htm#shift.gif - "Expandable 16 Stage LED Sequencer"

- http://www.ehow.com/how_5515694_make...r-circuit.html - 10 LED sequencer.

- http://www.cappels.org/dproj/ledpage/leddrv.htm - Driving LEDs from low voltage sources (lower than Vf)

- http://www.reuk.co.uk/LED-Dimmer-Circuit.htm - PWM dimmer for LEDs

- http://www.cappels.org/dproj/ledpage/leddrv.htm - Driving a LED form a low voltage

These sites have their own list of LED circuits

- http://www.bowdenshobbycircuits.info/index.html#menu - LED circuits and much more.

- http://www.qsl.net/yo5ofh/hobby circuits/led_circuits.htm - Includes some circuits connected directly to the mains -- be careful!!

- http://www.juliantrubin.com/fairprojects/electronics/leds.html - Lights and LED circuits

9.1 - High power LEDs and series resistors (yes, you can still get thermal runaway)

This was originally written in response to a thread where a high power (10W) LED had apparently died after a not particularly long life. This discussion assumes you can treat the LED as having a "resistance" (which you can't) but it is close enough to illustrate this effect. I should probably rewrite it to be a strictly more correct change in Vf.

The other problem with a fixed resistor is that Vf falls as Tj rises.

This means that the current tends to increase as the device gets hotter, which increases the current, which makes it hotter...

This is the normal thermal runaway issue that you get when powering a LED from a constant voltage.

However the same thing can happen with a resistor. The issue is, will it run away?

(runaway means increasing heat --> increasing power dissipation leading to an ever increasing power dissipation and eventual catastrophic failure. Even without this, the power dissipation can cause the temperature to rise above the limit where the device fails, but that is a thermal failure, not a thermal runaway.)

Let's model the LED as a resistor.

If the LED current is nominally 1A, and the battery voltage is 12V and it has a 1 ohm resistor in series with it, then it must be acting as if it has a resistance of 11 ohms.

So by simple calculation, it must be dissipating 11W (I'm using simple figures, so ignore the excess dissipation)

Lets say that it gets heated by this and the internal resistance falls to 10.5 ohms

The current rises to 1.043A, and the power dissipation rises to 11.4W.

So now it's going to get even hotter...

Let's instead, assume that the series resistor is 13 ohms and the current is 1A and the LED appears to have a resistance of 11 ohms. (Which means our power supply must be 24V).

The LED sees the same power, so its resistance drops, lets say to 10.5 ohms again. This time the current rises to 1.021 A, giving a power dissipation of 10.95W -- The power falls! So the LED will cool slightly.

In the first case, the LED current can still run away, in the second it reaches an equilibrium quickly (actually it will reach equilibrium in the first case too, but at a current dramatically higher than the nominal current.

In these 2 cases, we have assumed a voltage source with zero internal resistance and a series resistor. This is exactly the same as a real (imperfect) voltage source with an internal resistance.

It's pretty clear that increased internal resistance is a good thing in this case because it stabilises the current.

Wouldn't it be great if we could have an infinite internal resistance? Impossible?

Enter the current source...

A perfect current source is an infinite voltage in series with an infinite resistance. Because the load resistance is always low compared with the impedance of the supply, the current does not change as the load resistance changes.

In practice a constant current source employs neither infinite voltages not infinite resistances (and with it infinite power dissipation), but employs some circuit with feedback to ensure a relatively constant current over some range of load resistances.

So we have the LED with an assumed resistance of 11 ohms connected to a 1A constant current source. The current is clearly 1A, and the power dissipated is 11W, as it heats up and the resistance falls to 10.5 ohms, the current remains the same and the power drops to 10.5 watts, which is a lot lower. The device can still get hotter, and can still exceed Tj(max) but since the current does not increase, and the power dissipated does not increase, failure will be from excess temperature caused by the nominal current, not by thermal runaway caused by ever increasing current.

If you use resistors, you can't exclude the possibility of thermal runaway, but you can ensure that device power falls as current increases. To do that, at least half the supply voltage must be dropped across the series resistor. Clearly for high currents (i.e. high power LEDs) this is extremely wasteful.

Things are actually a little worse than I've suggested above. LEDs are not resistors. Their resistance does not fall as their temperature rises, their Vf does. Vf is also dependant on current, so in the three cases above, if the second case reflected what actually happened, the first would be worse (more current, higher power), and the last would be better (lower Vf even lower power).

If you've read my tome on driving LEDs, you'll note that I recommend constant current sources for high power LEDs. The above is an explanation that I've not put in there which justifies that recommendation.

This means that the current tends to increase as the device gets hotter, which increases the current, which makes it hotter...

This is the normal thermal runaway issue that you get when powering a LED from a constant voltage.

However the same thing can happen with a resistor. The issue is, will it run away?

(runaway means increasing heat --> increasing power dissipation leading to an ever increasing power dissipation and eventual catastrophic failure. Even without this, the power dissipation can cause the temperature to rise above the limit where the device fails, but that is a thermal failure, not a thermal runaway.)

Let's model the LED as a resistor.

If the LED current is nominally 1A, and the battery voltage is 12V and it has a 1 ohm resistor in series with it, then it must be acting as if it has a resistance of 11 ohms.

So by simple calculation, it must be dissipating 11W (I'm using simple figures, so ignore the excess dissipation)

Lets say that it gets heated by this and the internal resistance falls to 10.5 ohms

The current rises to 1.043A, and the power dissipation rises to 11.4W.

So now it's going to get even hotter...

Let's instead, assume that the series resistor is 13 ohms and the current is 1A and the LED appears to have a resistance of 11 ohms. (Which means our power supply must be 24V).

The LED sees the same power, so its resistance drops, lets say to 10.5 ohms again. This time the current rises to 1.021 A, giving a power dissipation of 10.95W -- The power falls! So the LED will cool slightly.

In the first case, the LED current can still run away, in the second it reaches an equilibrium quickly (actually it will reach equilibrium in the first case too, but at a current dramatically higher than the nominal current.

In these 2 cases, we have assumed a voltage source with zero internal resistance and a series resistor. This is exactly the same as a real (imperfect) voltage source with an internal resistance.

It's pretty clear that increased internal resistance is a good thing in this case because it stabilises the current.

Wouldn't it be great if we could have an infinite internal resistance? Impossible?

Enter the current source...

A perfect current source is an infinite voltage in series with an infinite resistance. Because the load resistance is always low compared with the impedance of the supply, the current does not change as the load resistance changes.

In practice a constant current source employs neither infinite voltages not infinite resistances (and with it infinite power dissipation), but employs some circuit with feedback to ensure a relatively constant current over some range of load resistances.

So we have the LED with an assumed resistance of 11 ohms connected to a 1A constant current source. The current is clearly 1A, and the power dissipated is 11W, as it heats up and the resistance falls to 10.5 ohms, the current remains the same and the power drops to 10.5 watts, which is a lot lower. The device can still get hotter, and can still exceed Tj(max) but since the current does not increase, and the power dissipated does not increase, failure will be from excess temperature caused by the nominal current, not by thermal runaway caused by ever increasing current.

If you use resistors, you can't exclude the possibility of thermal runaway, but you can ensure that device power falls as current increases. To do that, at least half the supply voltage must be dropped across the series resistor. Clearly for high currents (i.e. high power LEDs) this is extremely wasteful.

Things are actually a little worse than I've suggested above. LEDs are not resistors. Their resistance does not fall as their temperature rises, their Vf does. Vf is also dependant on current, so in the three cases above, if the second case reflected what actually happened, the first would be worse (more current, higher power), and the last would be better (lower Vf even lower power).

If you've read my tome on driving LEDs, you'll note that I recommend constant current sources for high power LEDs. The above is an explanation that I've not put in there which justifies that recommendation.