Learn what projects work best with brushed DC motors, brushless motors, servo motors, and stepper motors.

If you're building a project with moving parts, chances are you'll need a motor. But there are several different types of motors commonly available to Makers.

Brushed DC motors, brushless motors, servos, and steppers are the four most common types of motors that can be found in just about any project with motion involved. Using each of these types of motors in your project has its own set of benefits and potential issues.

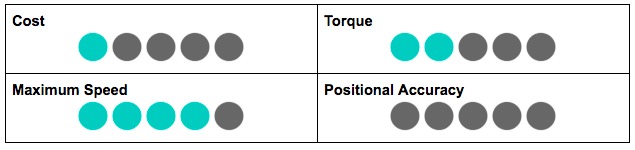

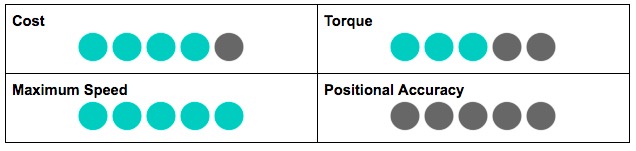

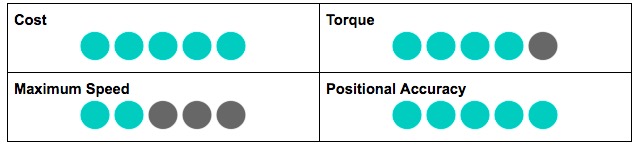

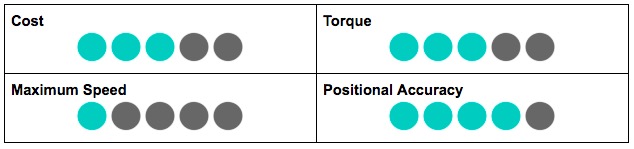

This article takes a look at the types of projects for which each type of motor is well suited and provides a basic ranking of cost, torque, maximum speed, and positional accuracy on a scale of 0-5.

Brushed DC Motors

Brushed DC motors are the cheapest, simplest, and easiest to control of any of the motor technologies discussed in this article. They are ideal for projects with more limited budgets that do not require any kind of precise positional control and for which power-to-weight ratio is less important.

Brushed DC motors are also useful for projects requiring extremely simple control. These types of motors can be controlled with nothing more than an on/off switch. Controlling their speed is simply a matter of adjusting the voltage supplied to the motor or varying the PWM duty cycle if a microcontroller is involved.

An example of a brushed DC motor utilized in a build.

Best Types of Projects for Brushed DC Motors

Beginner Robot Kits

Beginner robot kits almost universally use brushed DC motors because of their low cost and because they do not require advanced microcontrollers or complex programming to operate.

By using two motors, with two wheels, on either side of a robot chassis, you can build a fairly competent robot. Many of these types of basic robot kits are available from shops like Adafruit.

Builds Utilizing Vibration Motors

Vibration motors consist of a brushed DC motor with a weight attached asymmetrically to the motor shaft. You can use vibration motors in DIY controllers, Bristlebots, or any kind of project needing to deliver non-audible notifications to the user (like your phone in vibration mode).

Because of the simplicity with which brushed DC motors can be controlled, the intensity of the vibration can be modulated by simply adjusting the voltage supplied to the motor.

Example Projects

Brushless Motors

While brushless motors are beginning to replace brushed DC motors in high-end appliances and electric vehicles, they're also gaining in popularity for Maker projects, thanks to the availability of powerful-yet-affordable microcontrollers.

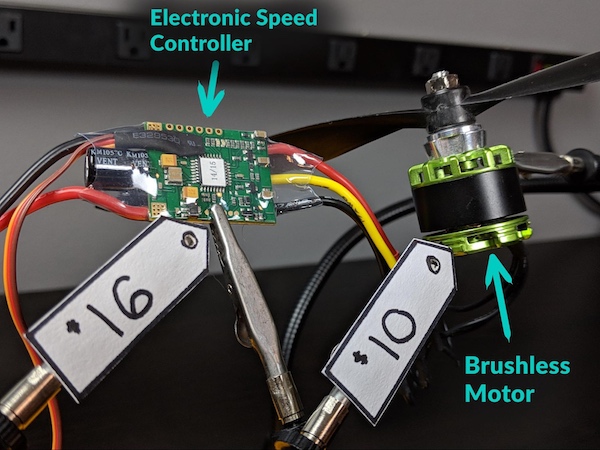

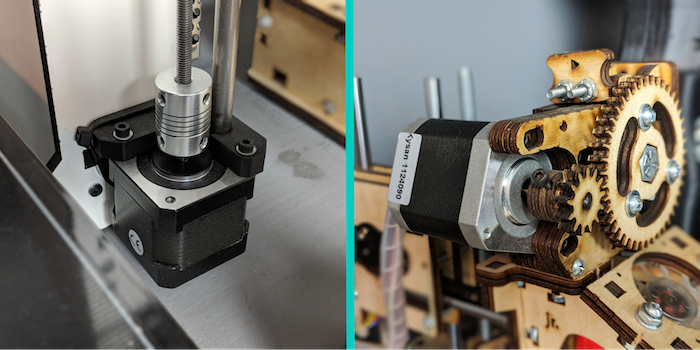

A couple of examples of brushless motors.

Brushless motors offer greater reliability, faster maximum speeds, and better efficiency compared with brushed DC motors. However, they are also more expensive than brushed DC motors, especially considering that they require specialized speed controllers to interface with microcontrollers, which can sometimes be more costly than the motor itself.

Oftentimes, the cost of controlling the brushless motor exceeds the cost of the motor itself.

Best Types of Projects for Brushless Motors

Hobby Aircraft Projects

Brushless motors are extremely useful in hobby aircraft projects including quadcopters, helicopters, and RC planes.

The higher efficiency of brushless motors compared with brushed DC motors has two major implications for RC aircraft projects:

- Brushless motors use less electricity to output the same power as a comparably-sized brushed motor, meaning Makers get more power from the same battery.

- Brushless motors have a higher power output for the same size motor. For aircraft, in particular, the power to weight ratio is critically important for performance, and brushless motors are useful for increasing that ratio.

Brushless motors are a good option for hobby aircraft projects.

RC Cars

RC cars, especially those used for racing, also benefit from brushless motor technology. A higher power to weight ratio is useful in RC cars for the same reason that it is useful for aircraft, for increasing performance.

For RC cars, brushless motors offer more torque and faster maximum speeds than gasoline-powered engines. Furthermore, brushless motors in RC cars provide near-instant peak torque output when power is applied. In contrast, gas engines need to reach higher speeds to maximize torque.

Camera Gimbals

If you are recording video of your project, a very useful tool for improving the professionalism of your videos by reducing shaking is a camera gimbal.

A camera gimbal is a device that keeps a camera steady, allowing for smoother footage. Gimbals do this by compensating for movement using three brushless motors, one for each axis of movement: roll, pitch, and yaw.

Steady your camera with a gimbal comprised of three brushless motors.

Servo Motors

Where brushed DC motors and brushless motors are designed for controllable speed, servo motors are designed for precise positioning.

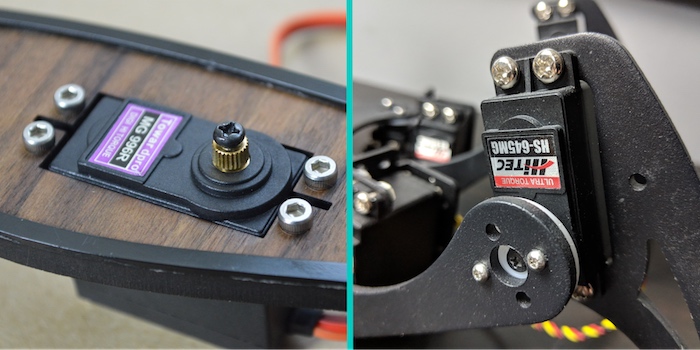

Servo motors are designed with integrated position sensing hardware that allows the servo’s controller to measure the precise angular position of the motor shaft, also called a horn. The combination of accurate positioning and high torque offered by servos makes them excellent choices for a range of robotics-related projects.

Examples of servo motors used in projects.

Best Types of Projects for Servo Motors

A Walking Robot

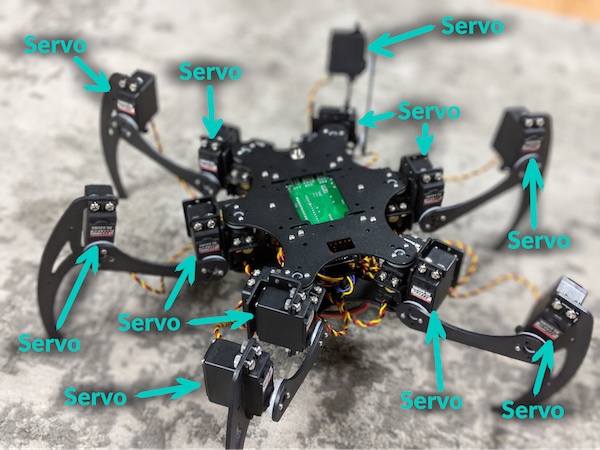

If you are building a walking robot, whether it has two legs, four, six, or even more, servos will almost certainly do the literal heavy lifting for your project.

In walking robots, servo motors act as joints.

In walking robots, servos act as the joints (and a bit like the muscles too but the anatomical analogy breaks down a bit here). The computer running your robot will use inverse kinematics to calculate the angle each joint must take to position the robot a certain way. Servo motors allow the controller to precisely control the angle of each joint on the robot.

If you're building a walking robot, chances are you'll use a lot of servo motors!

Robotic Arms

Servos are also useful for building robot arms. The high positional accuracy offered by servo motors allows a microcontroller to position the end effector of a robot arm with a high degree of precision.

This is the uArm Metal robot arm which is powered by servos.

Servos also deliver high torque at low speeds, courtesy of a gearbox between the motor and the servo horn, allowing robot arms to lift heavy objects.

Finally, a servo will resist external forces attempting to move the robot arm out of position. For example, if you build a robot arm and force it to extend past the point the microcontroller is seeking, the servo motors will move back into position once you stop applying force to the arm.

In contrast, stepper motors (covered in the next section) have no mechanism for figuring out if external forces move them out of position.

Steering for RC Cars

In RC cars, servo motors are commonly used for steering mechanisms. Since servos can be accurately positioned, and then repeatability returned to the center position, they are ideal for steering. From the steering racks on RC cars, to rudders on boats, to control surfaces on planes, to thrust vectoring on multirotors, servos allow all kinds of RC projects to steer.

Example Projects

Stepper Motors

Stepper motors, like servos, are designed for building machines requiring precise positional control and tracking.

The way stepper motors allow for positioning control is quite different from the method servos use. Servos are capable of absolute positioning. At any time, a microcontroller can query a servo's controller and get an angle back.

A stepper motor, on the other hand, uses relative positioning. Steppers rotate in discrete “steps” rather than using continuous rotation like brushed DC or brushless motors.

A typical stepper motor has 200 steps per complete revolution. So each time the servo steps, it rotates 1.8o. By keeping careful track of the number of steps a stepper motor has turned from a known starting position, a microcontroller can determine the location of the motor, or anything attached to it, with a high degree of accuracy.

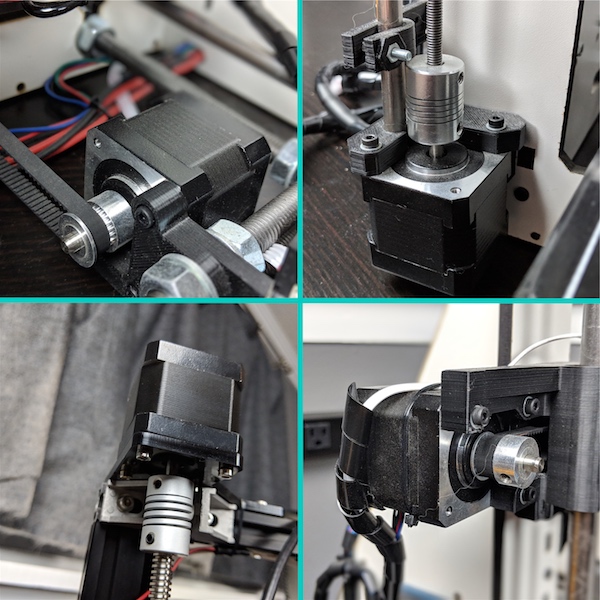

Examples of stepper motors in projects.

Best Types of Projects for Stepper Motors

3D Printers

Stepper motors are used in almost all desktop 3D printers. This motor technology allows 3D printer controllers to track the position of the print head to within a minute margin of error (usually on the micrometer scale). Furthermore, stepper motors deliver high torque at low speeds which is useful for moving a heavy extruder mechanism around the build envelope.

3D printers utilize stepper motors to track the print head's position.

CNC Machines

For reasons similar to 3D printers, stepper motors are used extensively in CNC machines. A CNC machine starts a job from a known zero position. The controller counts the number of steps the motors move, translated into distances according to the design of the belts stepper motors typically drive. This type of positional tracking allows for a high level of dimensional accuracy in CNC machined parts.

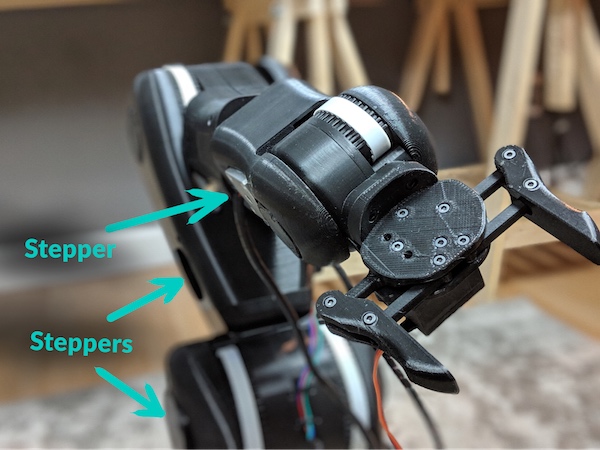

Large Robot Arms

The previous section explained how servo motors are used in smaller robot arms. Stepper motors are often used in larger robot arms. So, if you are designing a robot arm that will need to move heavy loads, the added torque of large stepper motors versus the torque delivered by servos will allow your robot arm to lift and move much heavier objects.

Stepper motors work well in large robot arms that require heavier lifting capabilities.

Example Projects