Nylon is a material that prints incredibly durable parts. However, it can be tricky to use! Learn more in this article.

The most common type of 3D printing filament, PLA, is fairly strong under static loads but is brittle and it loses most of its strength if subjected to temperatures 60°C and lower. ABS, the second most common type of 3D printing filament, is much more durable, but still cannot typically replace injection molded parts or be used for demanding functional parts.

Which brings us to nylon.

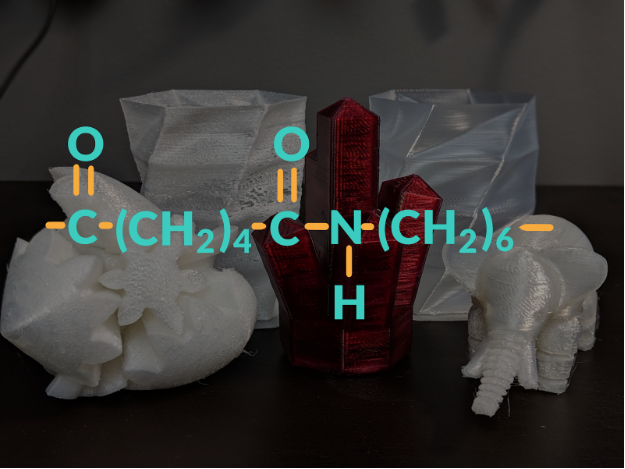

Nylon is a high-performance material that can be used to print incredibly durable parts, strong enough to be used as pieces in commercially-available products. Nylon is flexible when thin but its high inter-layer adhesion makes parts printed in nylon significantly stronger than any other common 3D printing feedstock. Furthermore, nylon has a low coefficient of friction, making it a good choice for gears, bearings, pulleys, threads, and other mechanical parts.

The downside is that nylon is quite a bit more difficult to print than PLA or ABS.

There are several formulations of nylon 3D printing filament, each with slightly different characteristics, applications, and printer settings. All types of nylon filaments have great mechanical strength, flexibility, and aesthetic.

Nylon is so flexible that the filament can be tied into knots without breaking or deforming.

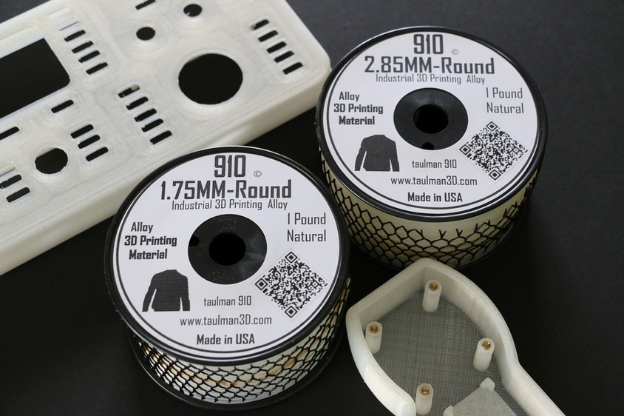

Taulman Alloy 910

Alloy 910 is a nylon formulation developed by Taulman3D, the market leader in nylon 3D printing filaments. Alloy 910 is designed to deliver extremely high strength 3D prints without any fillers.

Some formulations of nylon filament (and other types of filament) include fillers like glass or carbon fiber to increase its strength. However, these fillers degrade the surface finish of the parts and require larger nozzle sizes to avoid clogging.

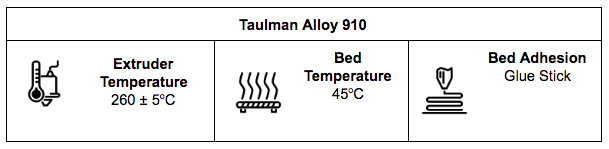

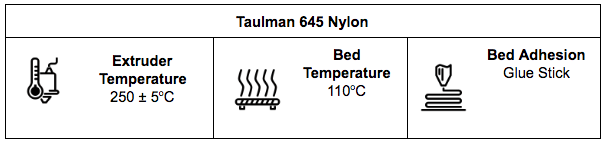

Taulman developed Alloy 910 specifically for 3D printing. It prints smoothly with minimal shrinkage, which minimizes the threat of warping. Alloy 910 demands the use of a high-end printer as it requires high temperatures of about 260°C to print.

Alloy 910 is available in only two colors: black and white. However, white nylon can be dyed using standard fabric dye, which is a process discussed in more detail below.

Another nylon formulation from Taulman3D, 645 nylon is designed to deliver the best mechanical strength of any other blends. It is designed for printing production-quality parts or prototypes that will be tested under demanding real-world conditions.

Like other nylon types, this material prints at a high temperature of 245 °C, so it requires a 3D printer equipped with an all-metal hot end. Also, 645 nylon can be difficult when it comes to good bed adhesion. Blue painters tape or bespoke build plate materials work well for printing with 645 nylon.

Like Alloy 910, Taulman 645 nylon is available in two colors: black and white.

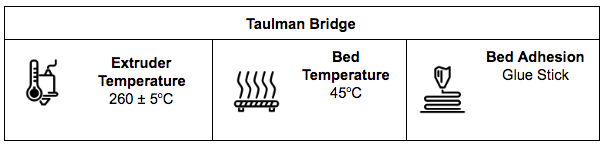

Taulman Bridge nylon is named after Taulman3D's goal of bridging the usability gap between 645 nylon and more common 3D printing plastics like ABS and PLA. The material was designed with five priorities:

- Maintaining high strength

- Improving bed adhesion

- Pricing the material close to more common feedstocks

- Translucency for non-destructive inspection

- Reduced shrinkage

Taulman has a page discussing the material's development in detail, but for a small sacrifice in strength, Bridge nylon is much easier to use. The material is not as strong as 645 nylon but it is still stronger than ABS, and it is much less fussy about bed adhesion.

Nylon is a “slippery” material, meaning it has a low coefficient of friction. This makes it a good choice for mechanical assemblies but has a very difficult time sticking to the print bed. Bridge nylon is not as low friction as other nylon formulations, so it sticks better to your build plate. That, combined with lower shrinkage than other nylons, makes Bridge nylon easier to print.

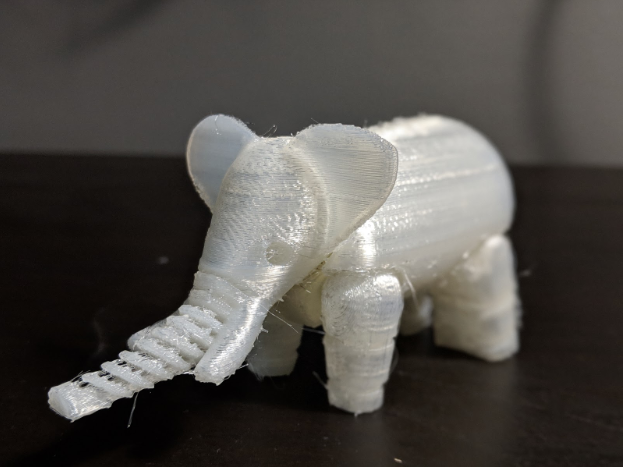

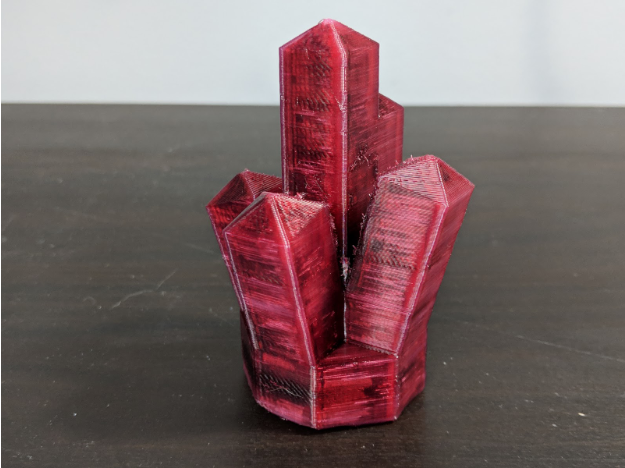

A sample print using Bridge nylon. Bridge nylon is meant to "bridge" the gap between 645 nylon and more common 3D printing plastics.

That said, Bridge nylon does still print at a high temperature of 250°C so it requires a high-end 3D printer and a heated bed for optimal bed adhesion and to reduce warping.

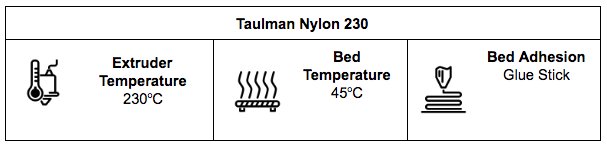

All the other nylon filament formulations listed above require high printing temperatures achievable only with a 3D printer equipped with an all-metal hot end. Therefore, they all require that you use a high-end printer.

Nylon 230, on the other hand, is specifically designed to be a more accessible type of nylon that can be printed using any 3D printer. The material is named after its target printing temperature of 230°C.

Furthermore, Nylon 230 does not require a heated bed—it can be printed on a common bed using materials such as Scotch Blue painters tape or BuildTak. It can optionally use a heated bed with a glass or aluminum surface coated with PVA glue.

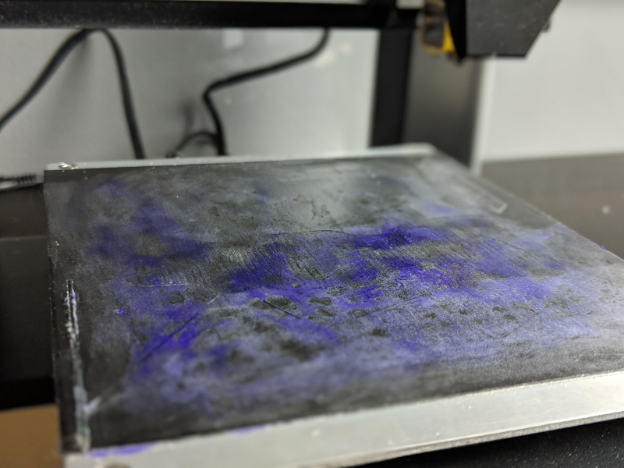

Using "disappearing purple" types of glue stick makes it easy to apply an even layer of glue because you can see where you placed the glue before it dries.

Nylon 230 is not quite as strong as Taulman3D's other types of filament, but is still very robust and a great alternative to PLA or ABS.

Nylon is extremely durable and low friction making it a great material choice for gears or other moving parts.

Storing and Drying Nylon Filaments

One of the major challenges of using nylon filaments is that nylon has a high propensity to absorb water from the surrounding air. Using a filament that has absorbed too much water can absolutely ruin the surface quality of your parts.

Considering the high temperatures at which nylons print, as the material extrudes any water trapped in the plastic will explosively vaporize and pop out of your 3D printer’s nozzle leading to bubbles and other imperfections in the print. Aside from degrading the aesthetics of printed parts, imperfections within the material can make the parts much weaker. Dry nylon, on the other hand, prints buttery smooth with a glossy, translucent finish.

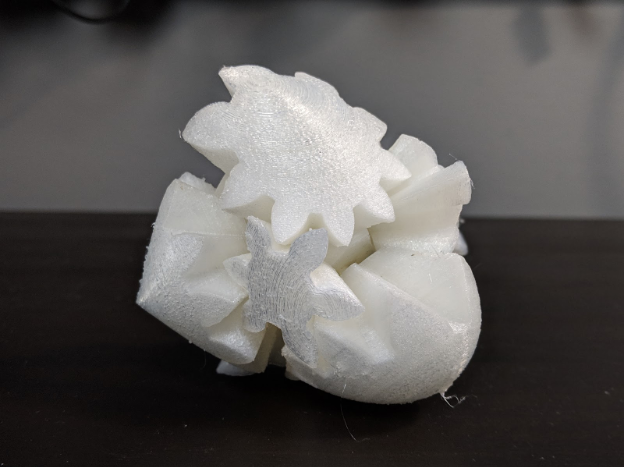

Using wet nylon in your prints will result in a weak and unappealing print.

You can actually hear when your nylon is too wet to use. If you listen closely to the video below, past the noise of the 3D printer’s fans and stepper motors, you will notice a crackling, popping noise. This is the sound of water within the nylon vaporizing as the material is extruded.

Therefore, it is critically important that nylon filament is properly stored. Rolls or loose coils of nylon filament should be stored in an environment with low humidity. There are many different storage options, but one of the easiest is to vacuum seal filament spools along with a generous helping of desiccant packs. Sealing your filament spools can be done with vacuum sealing units typically used for food storage. Desiccant packets can be purchased cheaply in bulk.

Store your nylon filament in a vacuum-sealed bag with moisture absorbing desiccant packs.

Nylon filament is so hygroscopic that the material can be rendered unusable for printing within six hours of exposure to the air. Therefore, the filament typically needs to be dried between print jobs. To dry nylon filament, place it in an oven at 170°F for six hours. After drying, the filament should be used immediately or vacuum sealed as quickly as the temperature of the spool allows.

Before you start your print, you can dry out your nylon in your kitchen's oven to ensure all moisture is removed from the filament.

Dyeing Nylon Parts

Nylon filament is available in a very limited range of colors compared to other common 3D printing materials like PLA or ABS. However, white nylon can easily be colored using fabric dye—nylon is, after all, commonly used in clothing.

The process of coloring your nylon 3D prints is a simple one. You will just need a few basic materials:

- Rit fabric dye in your choice of color

- A glass container big enough to submerge your 3D printed part

- A microwave

- A thermometer

- Tweezers or pliers or another tool for placing your part into the dye without dyeing your fingers

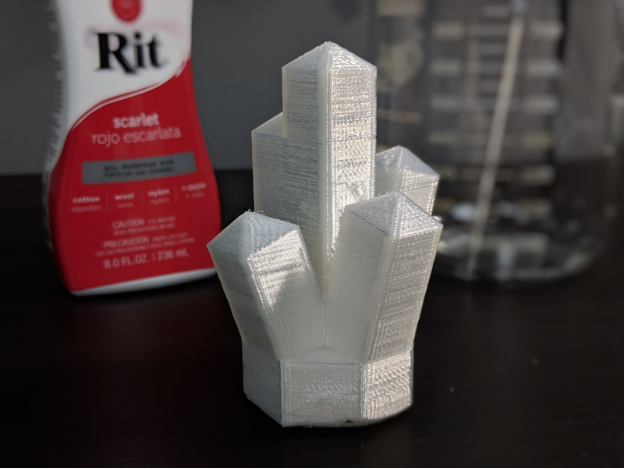

The starting model printed in Taulman Nylon 230.

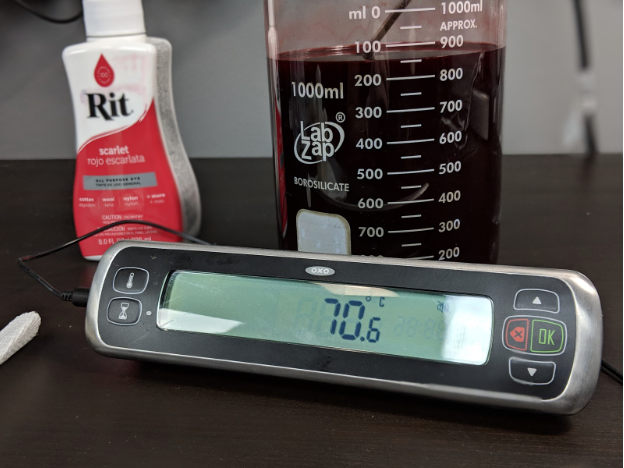

The fabric dye will penetrate the nylon part best if it is mixed with water between 60°C and 80°C. Using your microwave and thermometer, heat the water to 80°C. Then mix in the Rit fabric dye with a 5:1 ratio of water to dye.

Use water between 60 and 80 degrees Celcius.

Place your part into the hot dye solution. The longer the part stays in the dye, the darker its color will become. Therefore, it works best to dip the part into the dye for 30 seconds at a time, checking the color between each dip.

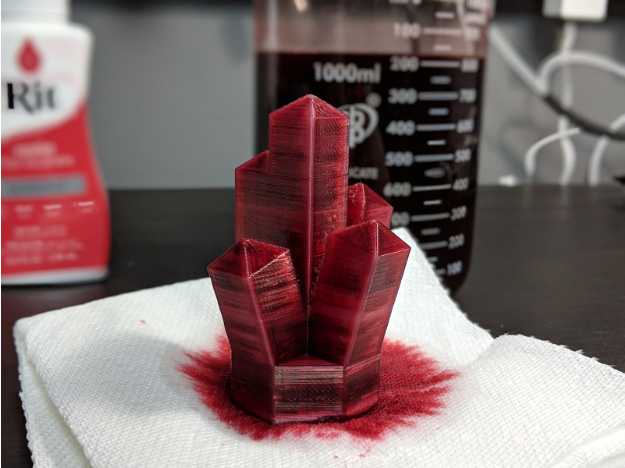

Dip your model into the dye in 30-second increments until you reach the desired color.

When the part gets to the color you want, rinse the part under running water to clean off any excess dye. Then let the part dry completely.

The finished product after dyeing and drying.

Have you ever printed with nylon filaments? Any tips and tricks we missed? Let us know about your experiences in the comments!