3D modeling is a great way to 'see' your projects in the prototyping phase, learn all about it right here!

The majority of the technologies you likely envision when you think about prototyping start in CAD software. All the various types of 3D printing, laser cutting, and CNC machining all start as models in 3D CAD. However, 3D CAD itself can also serve as a prototyping method in three main ways:

- First, 3D modeling can act as a kind of 3D sketching, helping to shape a product idea by forcing your brain to consider how it would exist as a real object.

- Second, 3D modeling can be used to create photorealistic renderings of an in-development product.

- Third, from a more engineering-related perspective, 3D CAD tools can be used to perform various types of structural, flow, and design analysis.

3D CAD can be used to “sketch” designs in 3D, to create photorealistic renderings, or to perform quantitative design analysis

Using the Sketching Tool in 3D CAD

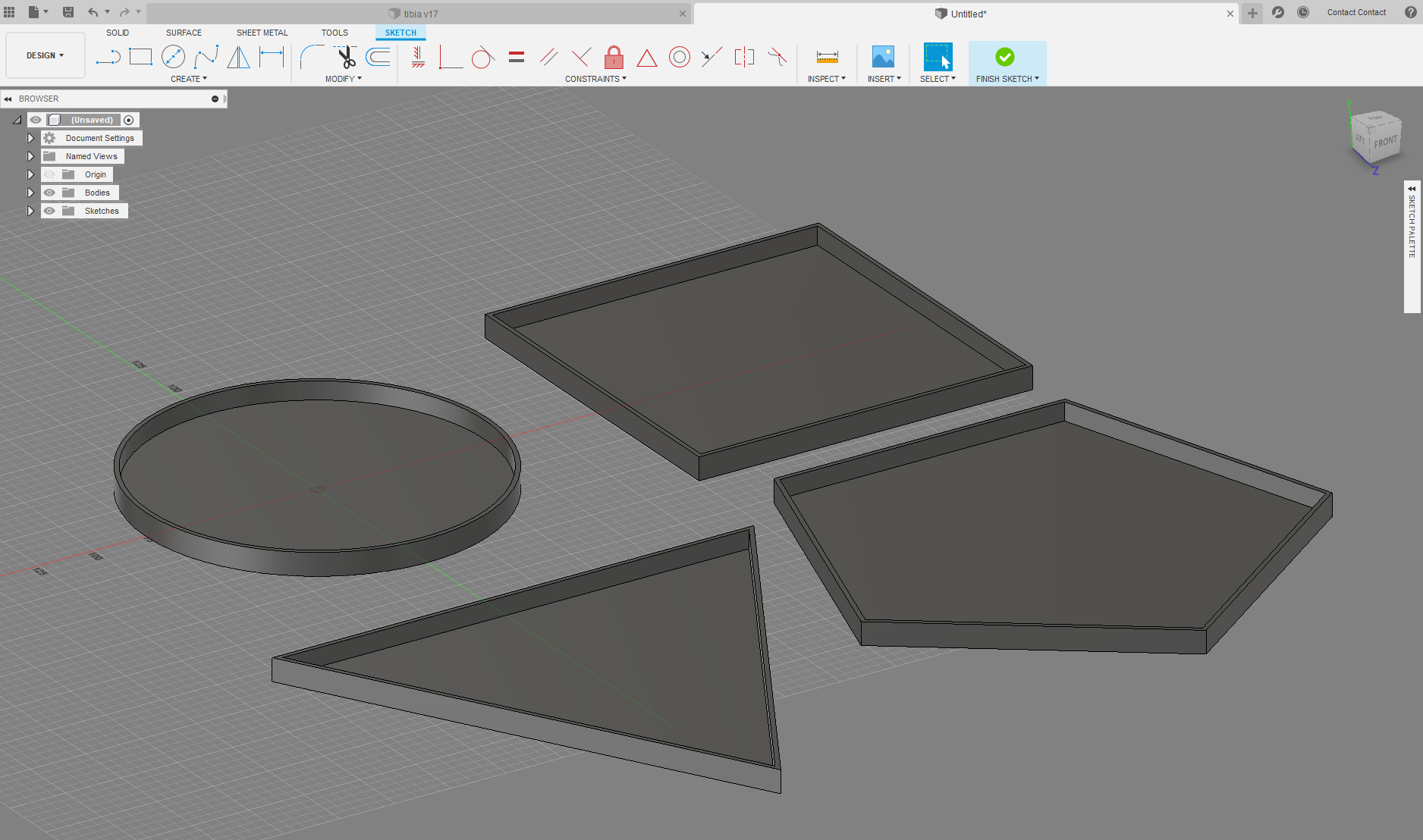

As a three-dimensional sketching tool, the same logic that makes the act of sketching and creating mockups useful applies to work in 3D CAD as well; translating your ideas into representations of physical objects, and all the problem solving that entails, helps to develop an idea.

Depending on your comfort level with sketching on paper versus 3D CAD, it can be an effective strategy to “sketch” directly in CAD, experimenting with different shapes within the software environment.

This screenshot shows some basic sketches for the shapes of an electronics enclosure in Fusion 360 CAD software

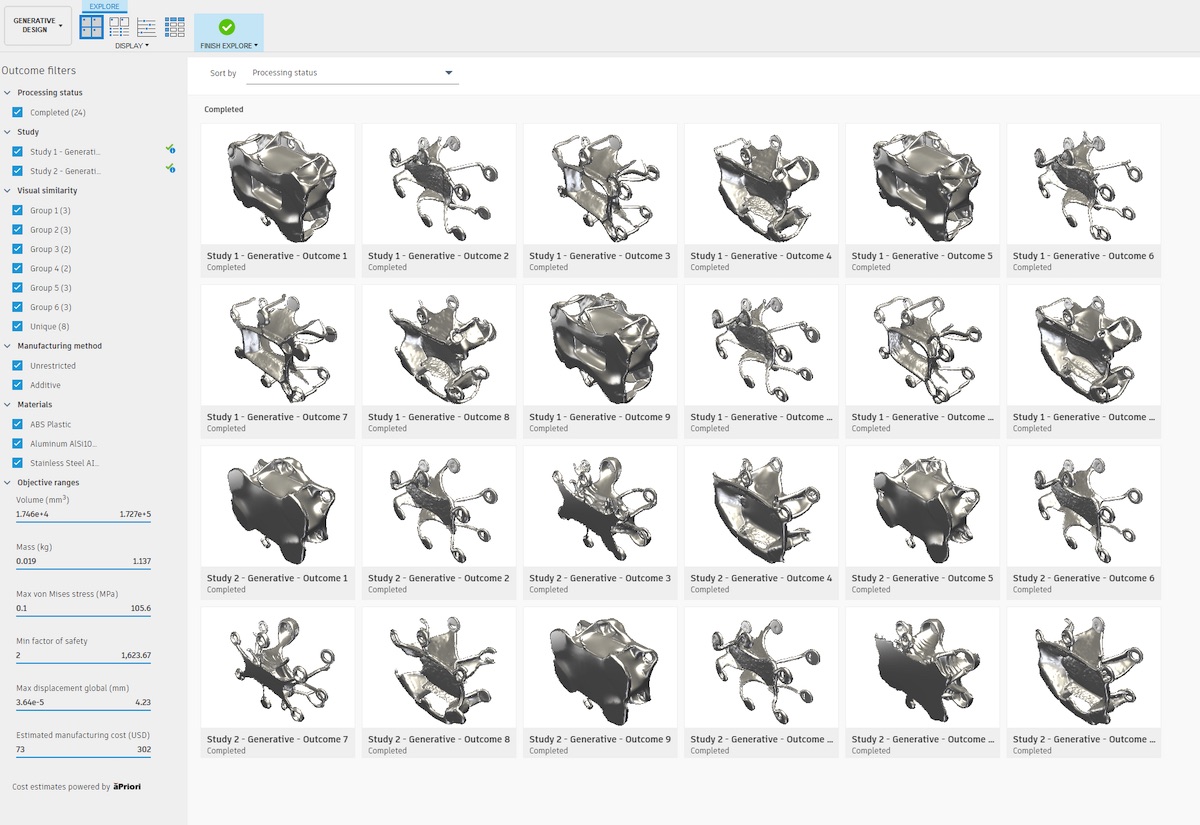

Furthermore, when it comes to quickly sketching different ideas for a product, recent advances in the field of artificial intelligence has given designers extremely powerful tools for allowing computer systems to create potentially massive sets of designs automatically, based on a series of design constraints.

Generative Design

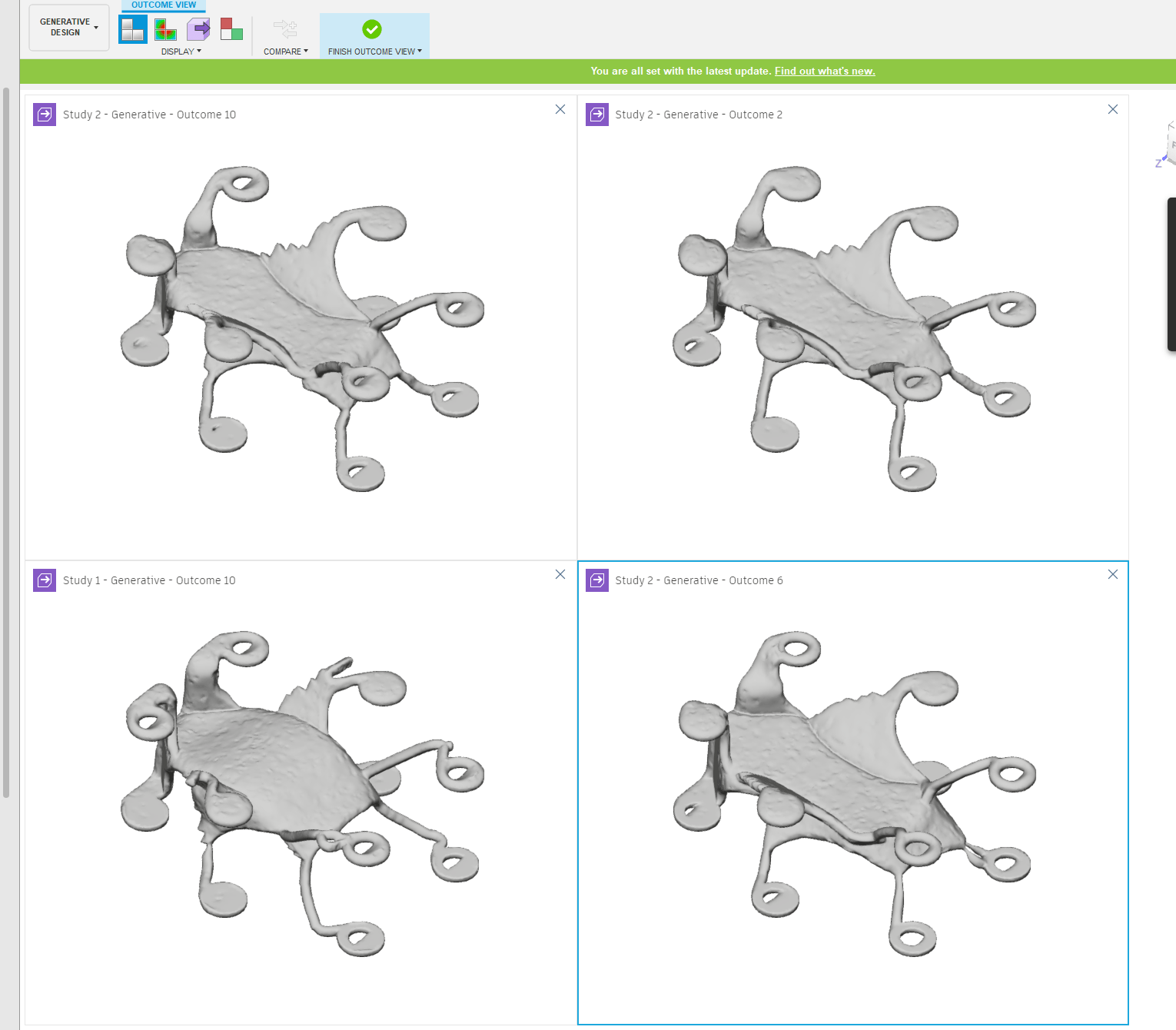

Generative design is a field in which algorithms take a set of constraints defining how a part must move, support loads, and fit with other parts, and from this information, create a set of designs from which product developers can choose.

The speed and accuracy with which generative design algorithms are able to create designs fitting a constraint set are far beyond what a human could accomplish.

This is an example of generative design, a field in which an algorithm generates a series of designs based on constraints and loads

Using 3D CAD to Create Renderings

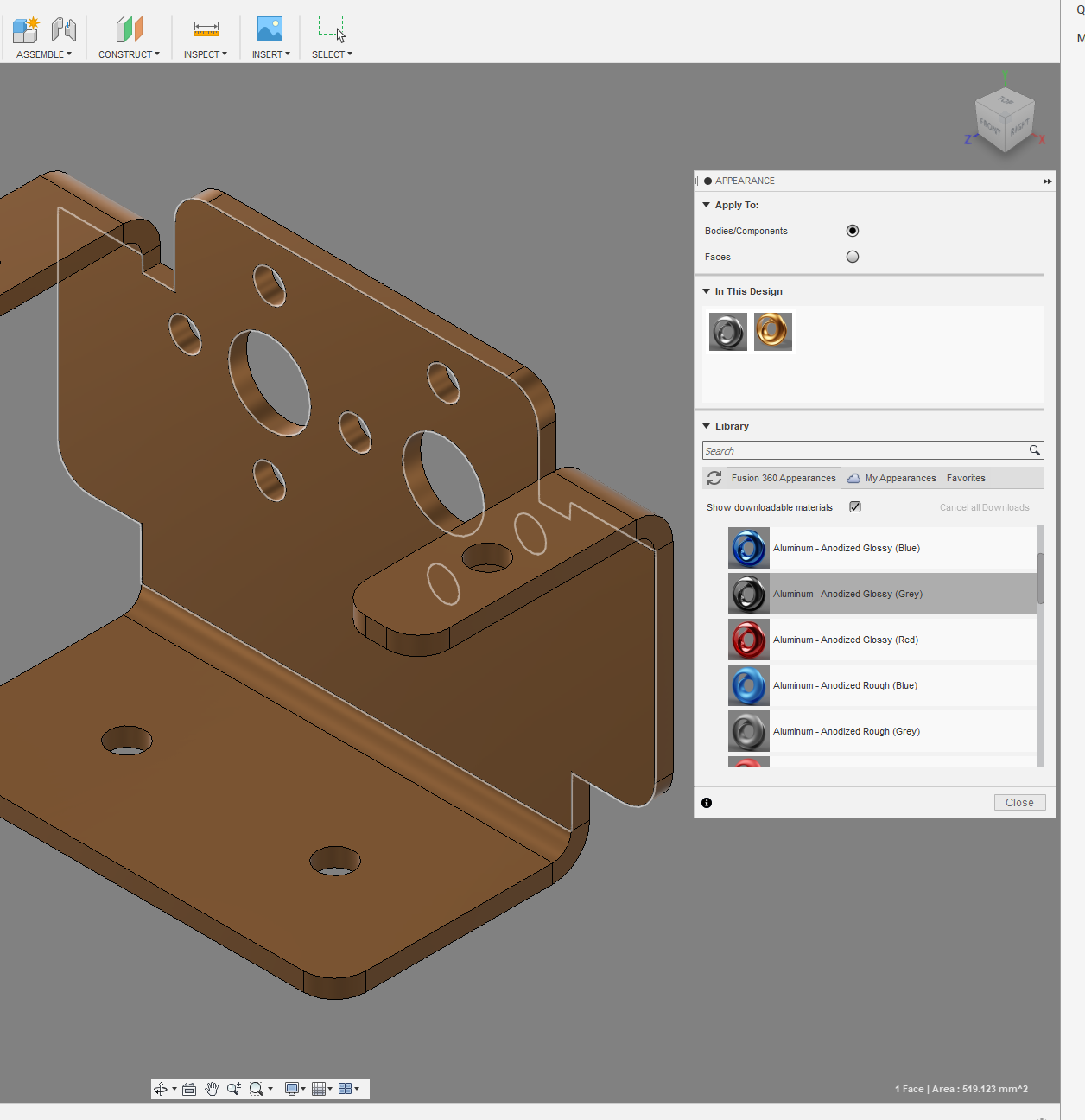

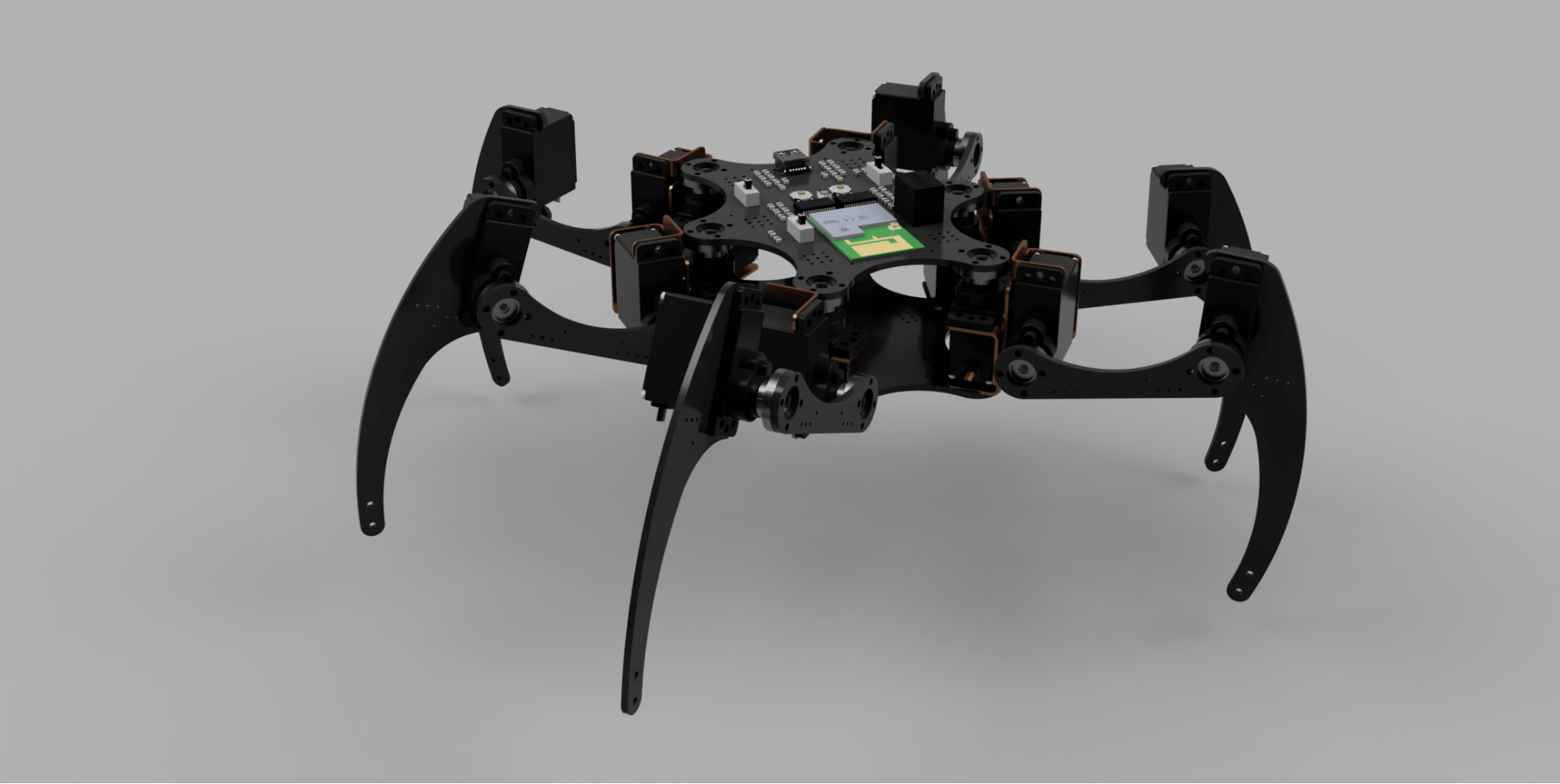

The second major use case for 3D CAD as a self-contained prototyping tool is for creating renderings. Unless you are an excellent artist who can draw realistic images by hand, 3D CAD grants the additional benefit of incorporating rendering functionality.

Most CAD programs include a materials library that allows designers to assign materials to various faces of their 3D models.

Autodesk Fusion 360 has a large materials library built into the software

The models can then be rendered to produce photorealistic images or animations of product design ideas. As with sketching out design ideas on paper, creating renderings in 3D modeling applications can serve as an effective design tool for presenting design ideas to team members, clients, or investors.

Using 3D CAD for Design Analysis and Simulation

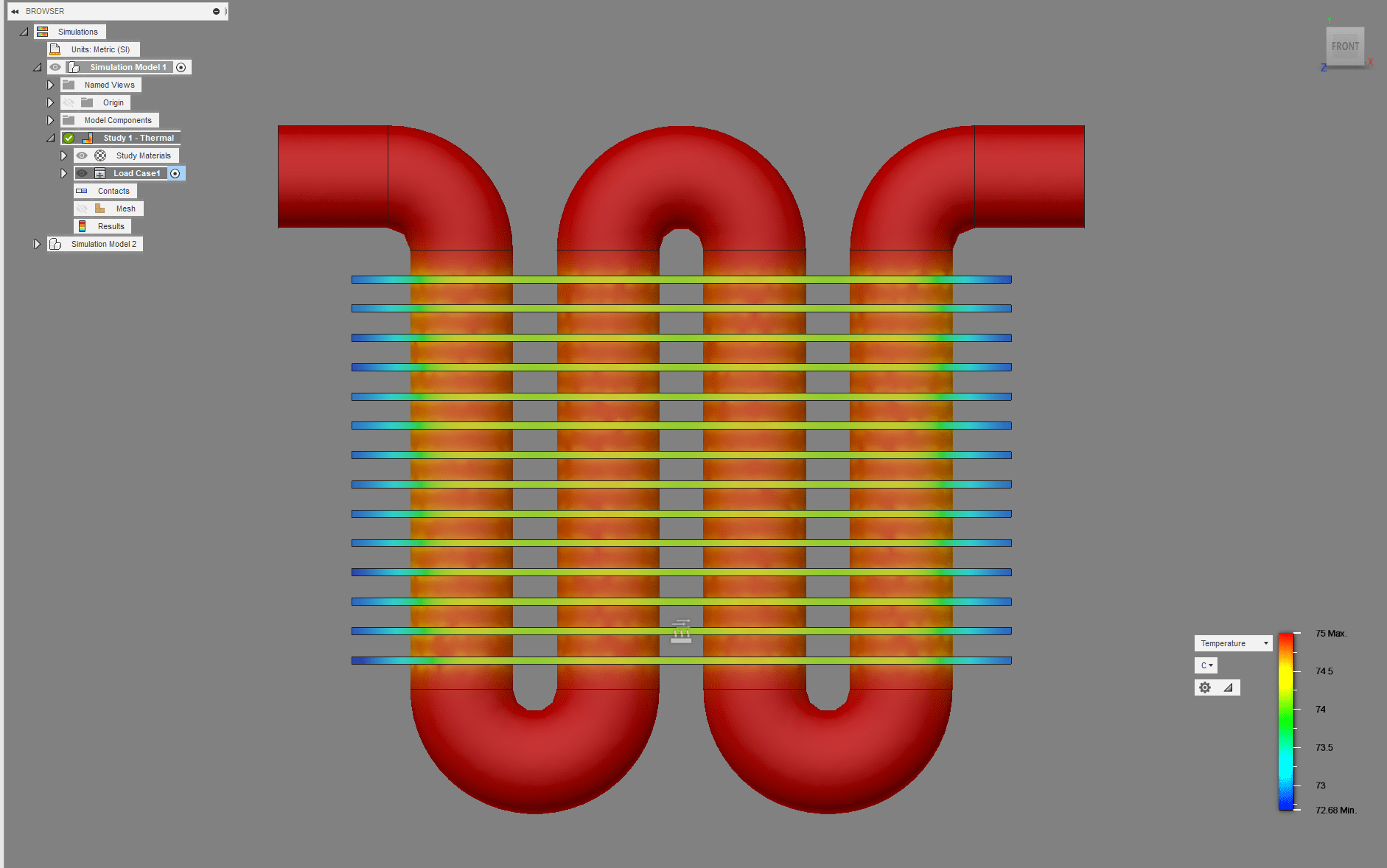

The third major use case for 3D CAD moves outside the realm of product design and into the area of engineering.

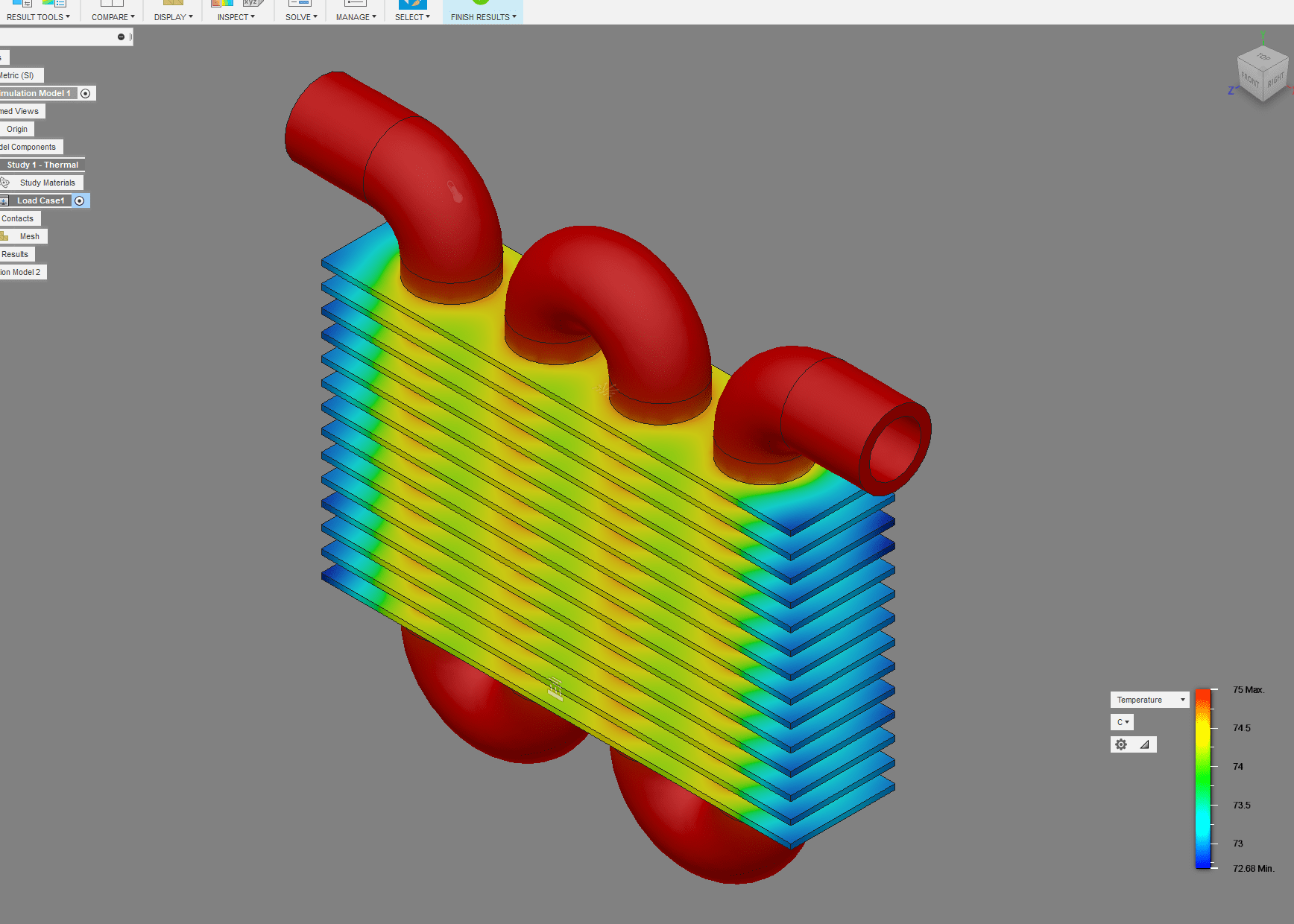

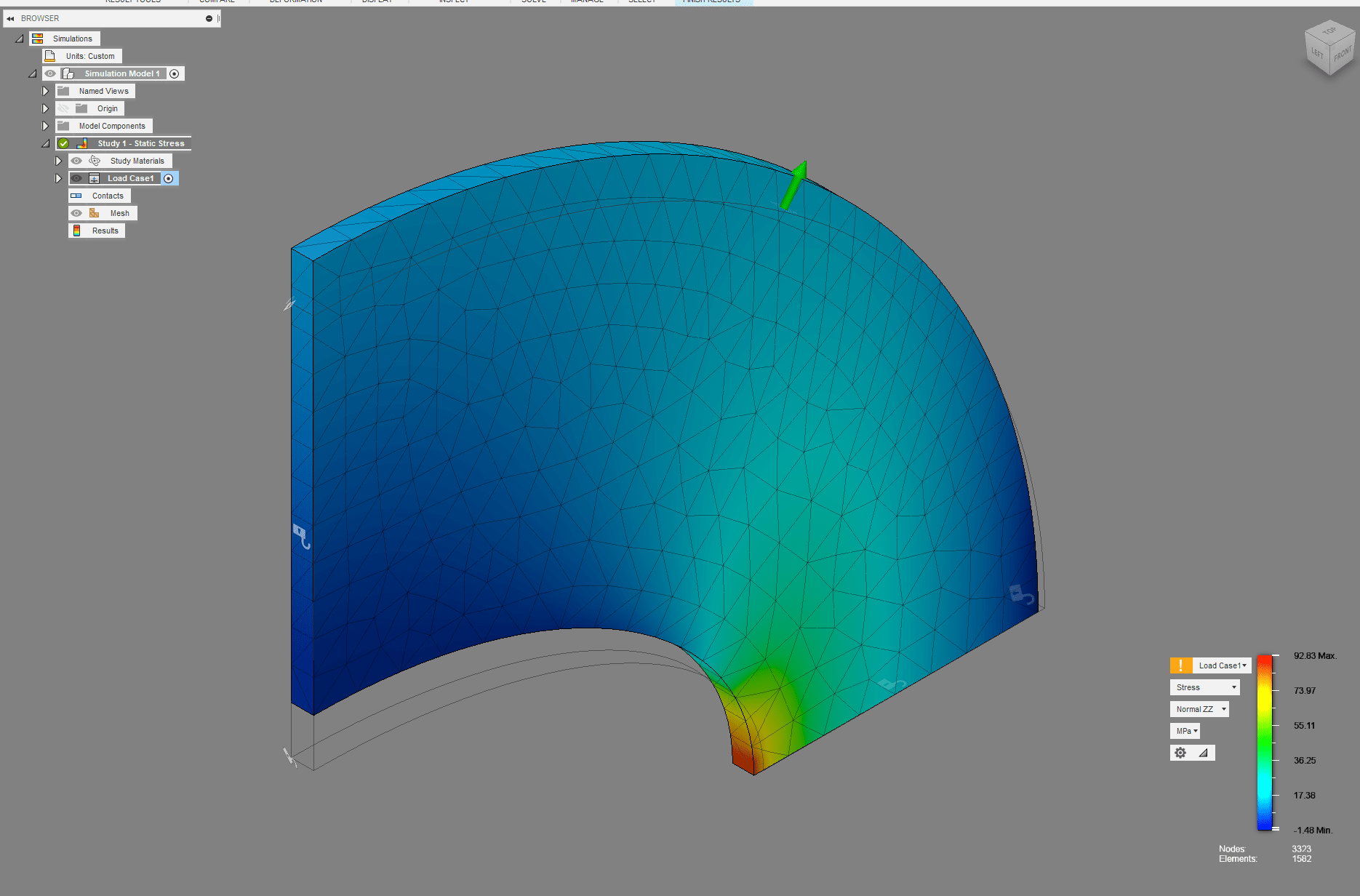

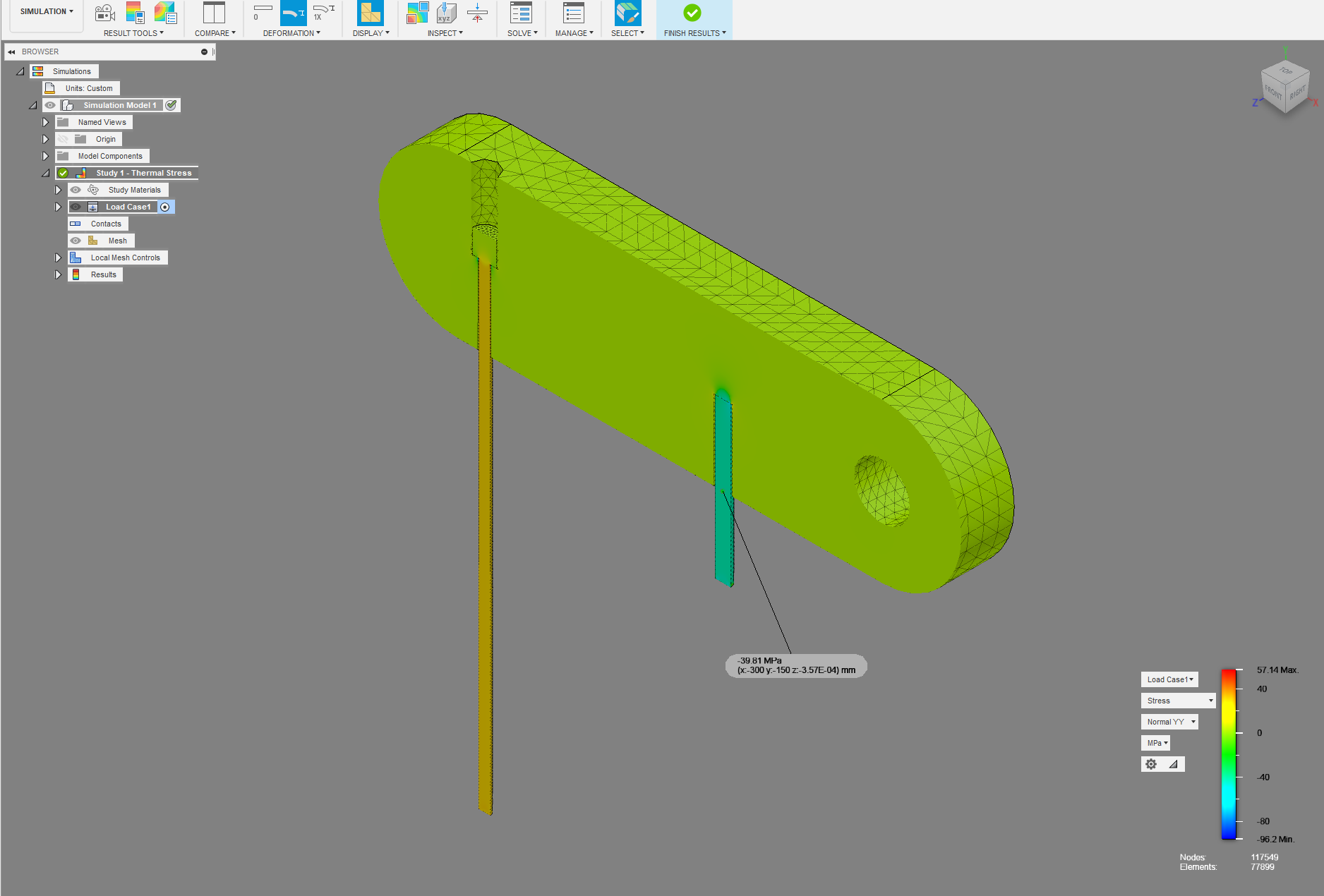

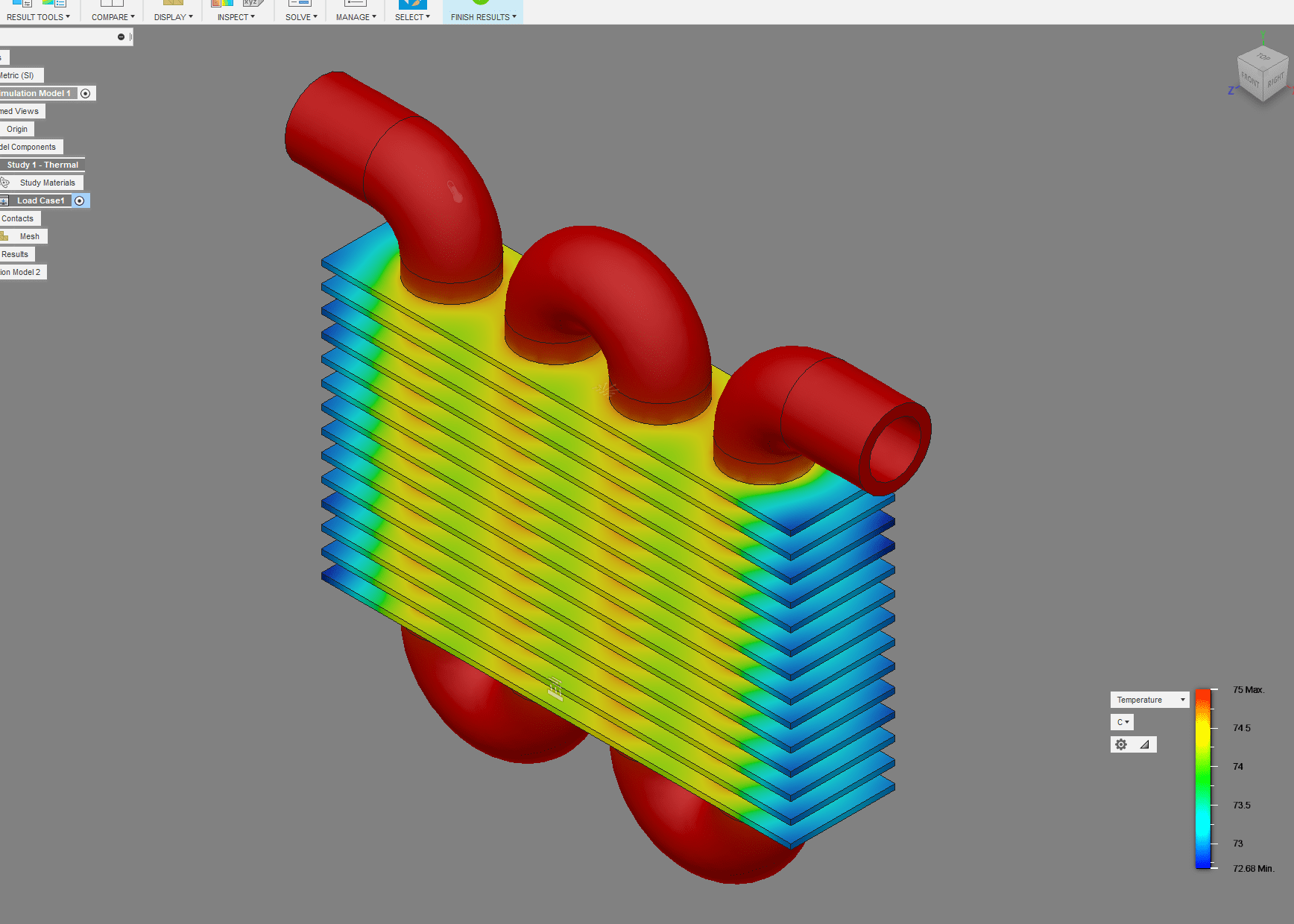

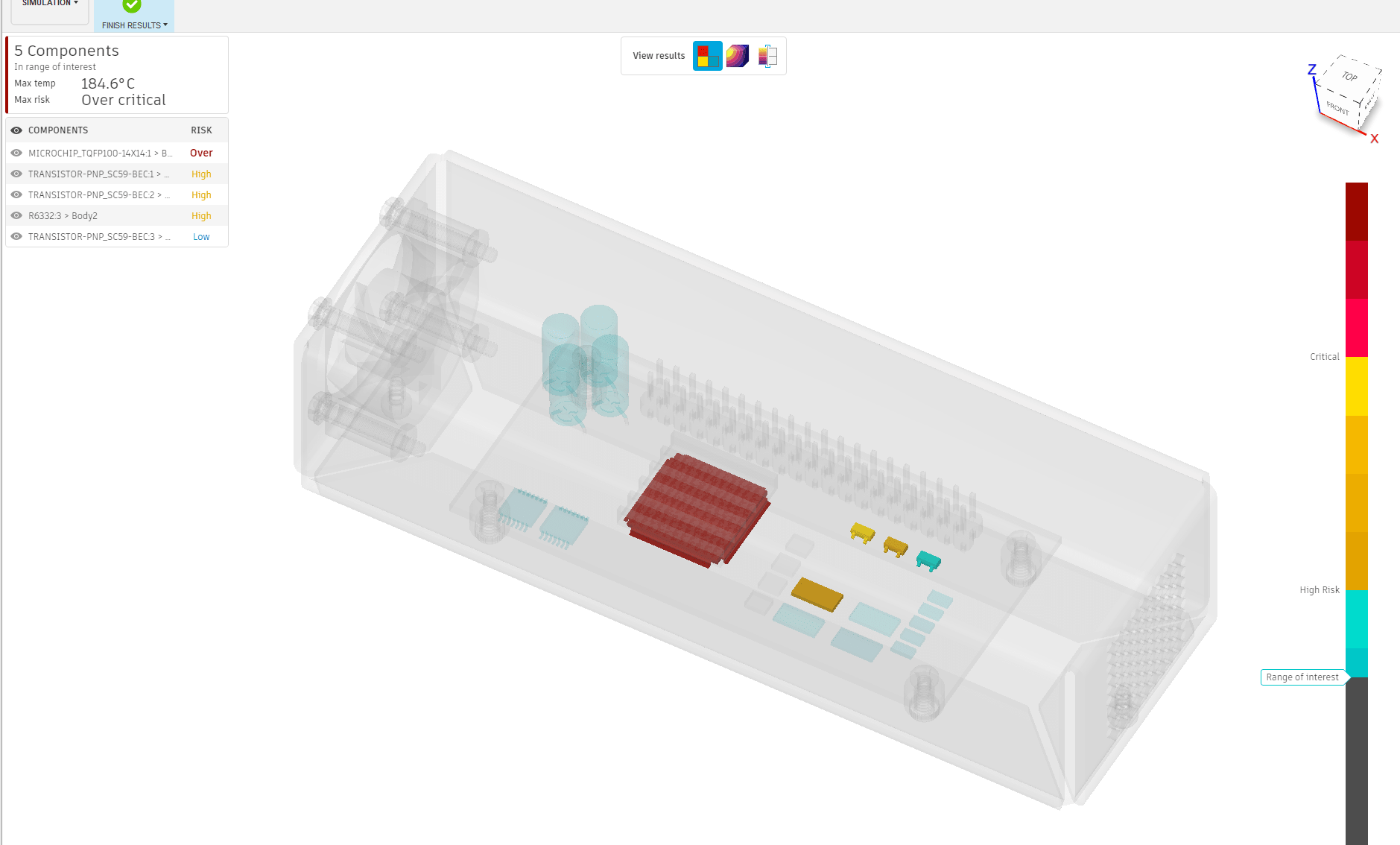

Most professional CAD programs include tools for performing various kinds of design analysis and simulation. This can include static stress analysis, modal frequencies analysis, structural buckling analysis, thermal analysis, shape optimization, electronics cooling analysis, fluid flow analysis, or a variety of different techniques that allow an engineering team to validate various aspects of a product design before producing physical prototypes.

This is a static stress analysis

This image shows the results of a thermal stress analysis

This type of design analysis is certainly useful, or even necessary, before a product is finished and moved on to manufacturing. Therefore, it can be a wise decision to perform different types of design analysis for the prototyping phase as well, in order to create more useful prototypes that are closer to the finished product in terms of their overall design.

Design analysis can also save time and money, especially if your product design requires more costly prototyping methods, like metal 3D printing or any prototyping that involves tooling costs.

This analysis shows how heat flows through this part

This screenshot shows an electronics cooling analysis with certain parts on a PCB being analyzed

3D Modeling and Rendering Offer a Variety of Prototyping Tools

3D modeling and rendering is not only the starting point for many different prototyping technologies used to make a dimensionally-accurate and functional prototype, like those discussed in the next several articles in this series but also 3D CAD itself can be a prototyping method.

Creating 3D models presents similar challenges to sketching and creating product mockups. Translating a design idea into a 3D model involves a great deal of problem-solving. Tackling the challenges involved in creating a physical product that will be used by customers helps to refine ideas and guide further product development.

Furthermore, generative design can be used to automatically create several designs based on information like the loads that will be placed on a part. Using artificial intelligence, generative design creates a set of potential designs that can either serve as end-use parts or guide further design efforts.

Based on a set of constraints, generative design creates a number of designs

Photorealistic renderings can also be created in many 3D CAD programs. Rendering technology, coupled with features allowing materials to be assigned to a design, allows product designers to create aesthetic prototypes in a virtual workspace. Renderings can be used to inform design decisions or as a communication tool.

Photorealistic renders allow designers to better explore aesthetic choices in prototype designs

Last, CAD software can be used to perform quantitative design analysis to explore the stresses acting on a part, thermal performance, flow analysis, and other types of design examination. This type of analysis can help developers avoid potential issues with a design once they start creating real prototypes

3D CAD is the starting point for most of the other prototyping technologies discussed in this series. One of the most accessible technologies is 3D printing, which allows designers to quickly make dimensionally accurate prototypes