Learn about the importance of power curves when choosing a motor size for your robotics projects.

While certain projects require certain motor types, it often isn’t clear what motor within that type is ideal. While for a drone you need a brushless motor, how do you choose which one? When choosing a motor for a robotic arm or leg actuator, how do you know how much power you need and what gearing is necessary? This guide will help answer some of these questions.

Applications in Robotics

On the surface, looking at the numbers and doing some simple math seems easy. However, it can be complicated by power curves, thermal considerations, and gearing.

In this article, I’ll discuss how to size motors for two of the most common applications: drive systems and actuators.

For a drive system, the motor turns a wheel, tank tread, or another continuously rotating element to provide locomotion. For actuators, the motor usually runs through an extreme gear ratio to output just a couple rotations per second, but at very high torque for moving a heavy, offset mass like on a robot arm.

In order to properly size a motor, you need to know what its job will be — that is, what the intended/maximum weight or load is, and how fast it needs to be capable of going.

Motors By the Numbers: Power Curves

In Part 1 of this series, I touched on motor controllers and electric power. Now let’s talk about mechanical power. No motors are 100% efficient, but their efficiency changes drastically depending on how fast they are running in comparison to their max (no-load) rpm. This will make much more sense once we look at a typical motor power curve. Let's look at a couple of great examples from VEX.

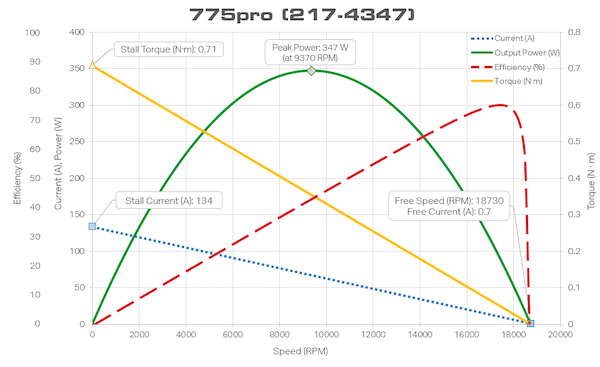

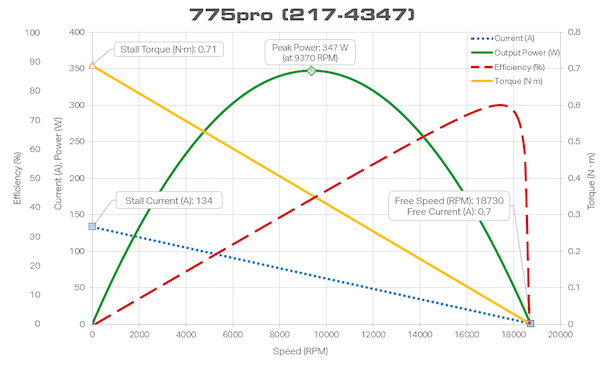

775 Pro Motor

Let’s start talking with the 775 Pro. This is a brushed motor extremely similar to the one I’ve used in a 30-lb combat robot drive system due to its small size and weight, but considerable power and high speed.

To drive my robot at less than 200 mph I needed to gear it down with a 16:1 planetary gearbox. Despite this, it was still lighter and more compact than other options.

You can clearly see from this power curve why you need to gear it down. The 75% peak efficiency occurs just below its top speed of 18730 rpm, right around the 17500 rpm mark. This means that at max rpm it is generating much less waste heat than if running at its peak power output where it is only around 44% efficient.

Motor curve data for a 775pro motor. Image courtesy of VEX.

Almost everyone knows that electric cars are fast because they accelerate with instant torque because when a motor starts from a dead stop it delivers 100% of its stall torque. However, with 0 rpm it is also producing no mechanical power and is 0% efficient at stall.

Clearly from this curve, operating at the low rpm range would fry this motor as almost all the energy pushed through it turns into waste heat.

CIM Motor

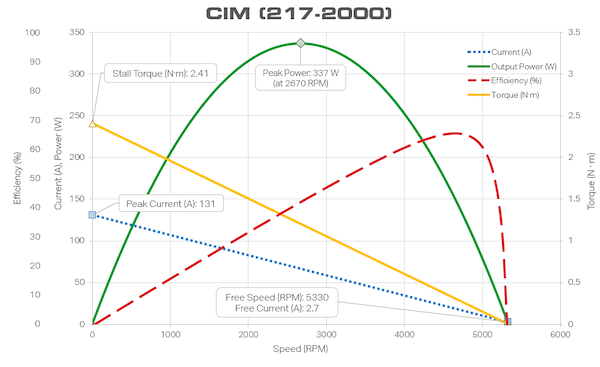

Here is the motor curve for the much bigger and heavier CIM motor.

Motor curve data for a CIM motor. Image courtesy of VEX.

Both of the above examples are for brushed motors, but of very different sizes. Both have around the same peak power output. Both run at 12V and have very similar stall current ratings around 131 amps, but the 775 Pro is for very different applications from the CIM.

The CIM is more ideal for continuous operation due to its larger thermal mass, and with a max rpm of only 5330 and far higher stall torque, it doesn’t require as heavy gearing for most applications.

It’s very popular in FIRST robotics competitions, where its ability to be used with just a one- or two-stage gear/chain reduction totaling under 10:1 reduces the overall cost to use it over a 775-Pro that might require 40:1 or higher reductions to do the same job. Reductions this high would mean using a $70-90 planetary gearbox instead of far cheaper chain sprockets or spur gears.

How Power Curves Affect Robotics Design

The big takeaway here is that for a motor to be capable of working for your design, it needs to be able to provide enough power, preferably where it's most efficient near its top-end speed.

For choosing a gear ratio, the gearing must be such that at the desired speed you get at least as much torque as needed. Keep in mind that the motor will automatically slow down and draw more current in order to produce more torque, which means you will always be able to run as fast or faster than needed with lighter loads so long as the torque produced is enough with the maximum load.

While most motors will not provide you with a power curve chart like the ones we looked at in this article, you can assume the curve based on stall torque, stall current, voltage, and no-load speed. Having these numbers in mind allows you to use simple arithmetic and linear algebra to determine whether a motor will work for your build or not.

You can find a deep dive into the actual calculations and assumptions used for making these design decisions with real-life examples in Calculating Motor Sizing.