Learn all about the different techniques to improve your prototypes, to get the best possible outcome for your projects!

Prototyping is a critically important part of every stage in the development of a new product. Early, low-fidelity prototypes can help to refine basic ideas of how a product or system will work, helping to make changes and guide future development from very early in the development process. Early prototyping can save immensely on time and money later on.

Medium-fidelity prototypes can be used to validate shape and form, to gather early design feedback, to test basic functionality, and to help make important design decisions towards finalizing a design.

End-stage, high-fidelity prototypes can be used to do final functional testing, to get feedback from end-users, to help gather outside investments or crowdfunding Backers, and to help while working with manufacturers.

Today, product designers have access to a vast range of technologies for making all kinds of prototypes. These range from old-school methods like pen-and-paper sketching or cutting blocks of foam, to newer technologies like 3D printing and CNC machining.

Different Prototyping Techniques

Each prototyping method and technology comes with its own set of advantages and drawbacks so each has a unique place depending upon the objectives of a product design team. The first half of the video below, from LinkedIn Learning, shows a product design agency called Prime Studio using a variety of different prototyping methods to design a knife block.

This article series provides an overview of some of the most common prototyping methods for a smaller product development team with a look at the pros and cons of each technology.

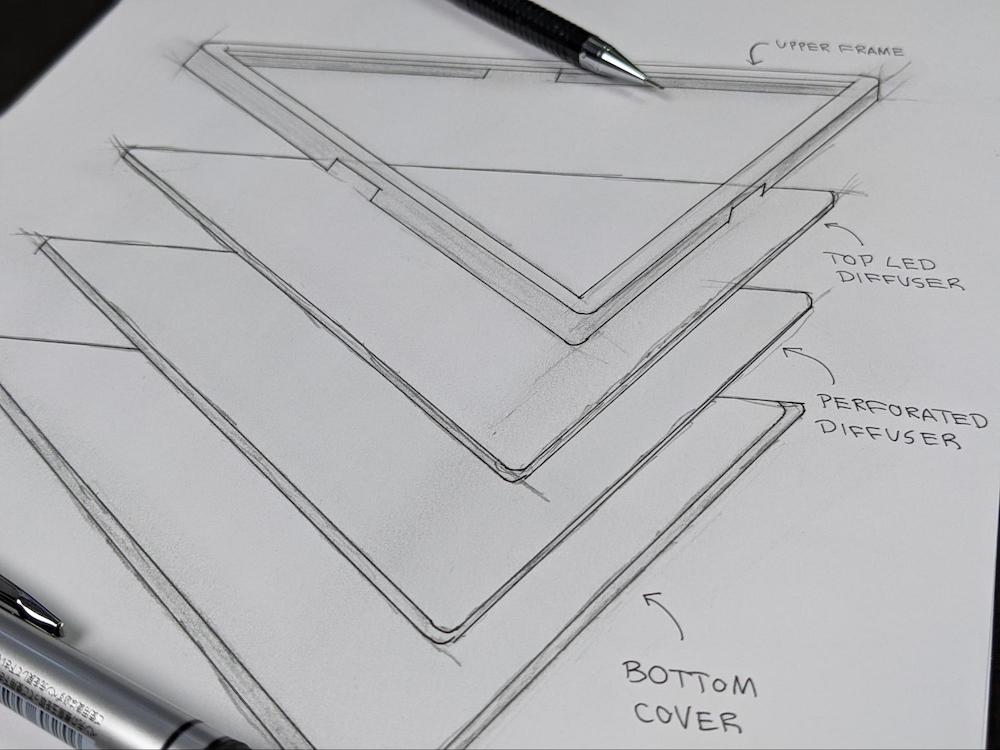

Sketching Out a Design

Sketching is often the first prototyping method a product designer will use to begin the process of translating an idea into a physical product.

Sketching can be done with a simple pencil and paper or using drafting tools, or with a stylus-enabled tablet or computer.

The point of sketching out prototype ideas is to begin working on the many challenges involved in starting with an idea and building a salable product.

Building a Mockup of the Design

Another method of creating prototypes quickly and with minimal cost or tools is creating product mockups.

Mockups can be made from cardboard, paper, foam, clay, or just about any material that is readily accessible and easy to shape. Again, the point is to explore different ways of bringing a product idea to life.

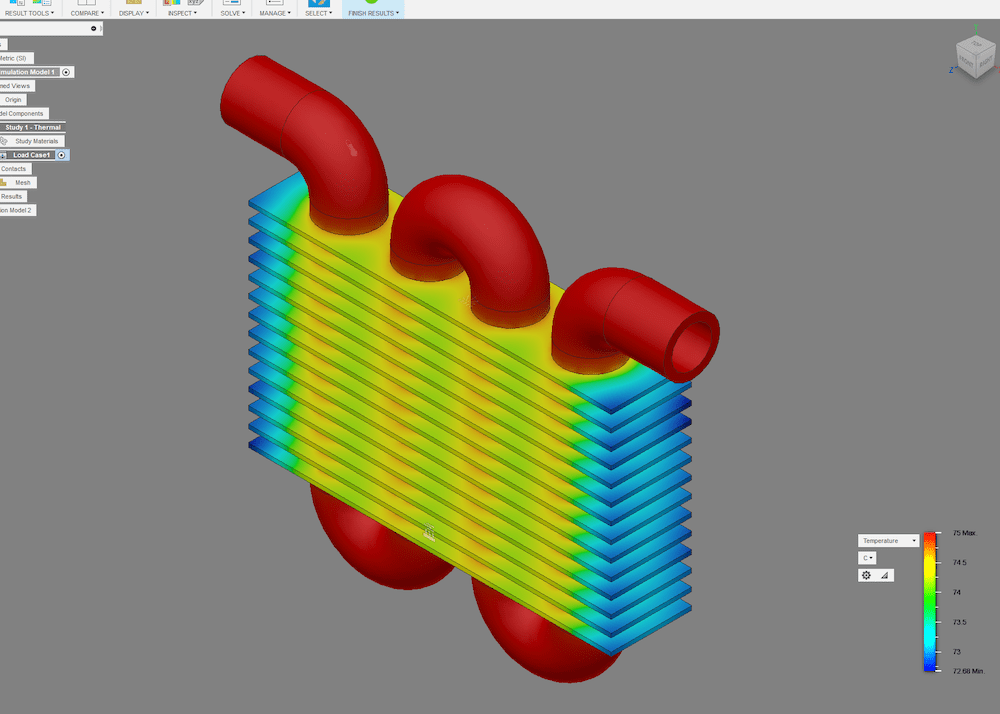

3D Modeling/Rendering Your Design

3D modeling and rendering is the first step towards making higher fidelity prototypes with computer-driven tools. But 3D modeling and rendering can itself be a prototyping method.

Using CAD software, designers can explore numerous potential design revisions. Many CAD programs also include various design analysis tools that can help refine a design in more technical tools.

3D Printing Prototyped Designs

One of the most accessible technologies used to create functional product prototypes is 3D printing.

A 3D printer capable of producing highly accurate functional prototypes can be purchased for a couple of hundred dollars. 3D printers can be used to create prototype parts from a variety of different types of plastic.

Prototypes From CNC Machining

CNC machining is another computer-driven prototyping technology. There are several types of CNC machines available to product designers depending upon the geometry of the part being produced.

They all have the ability to create parts with extremely tight tolerances and from a vast range of different materials. For some materials, like metals, CNC machining is a more affordable prototyping technology than many other methods.

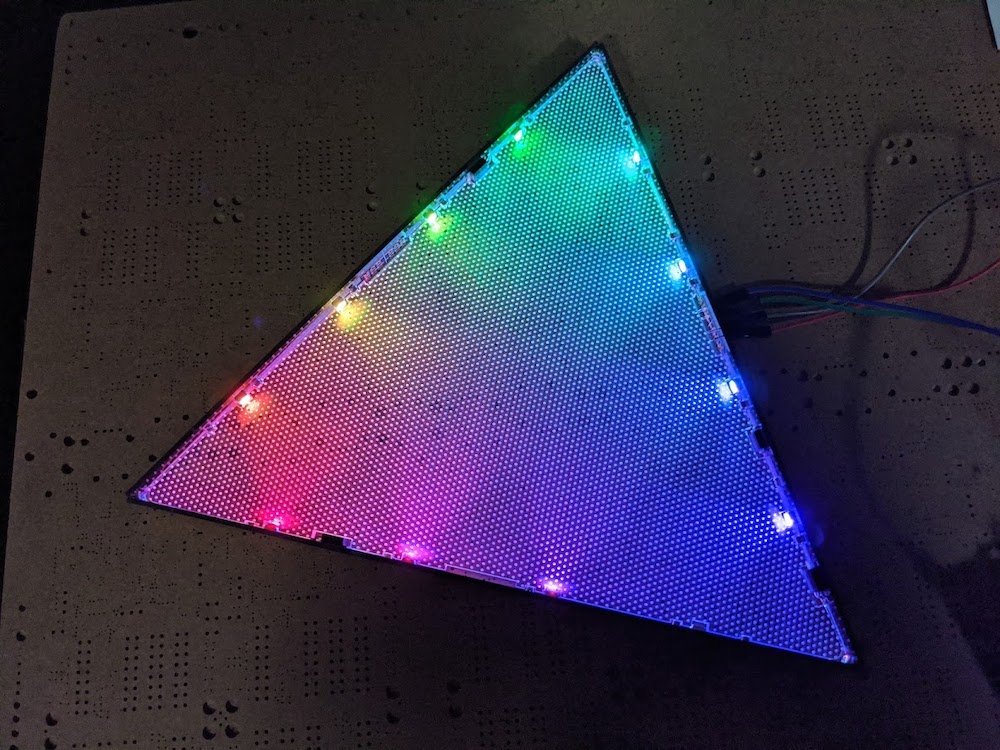

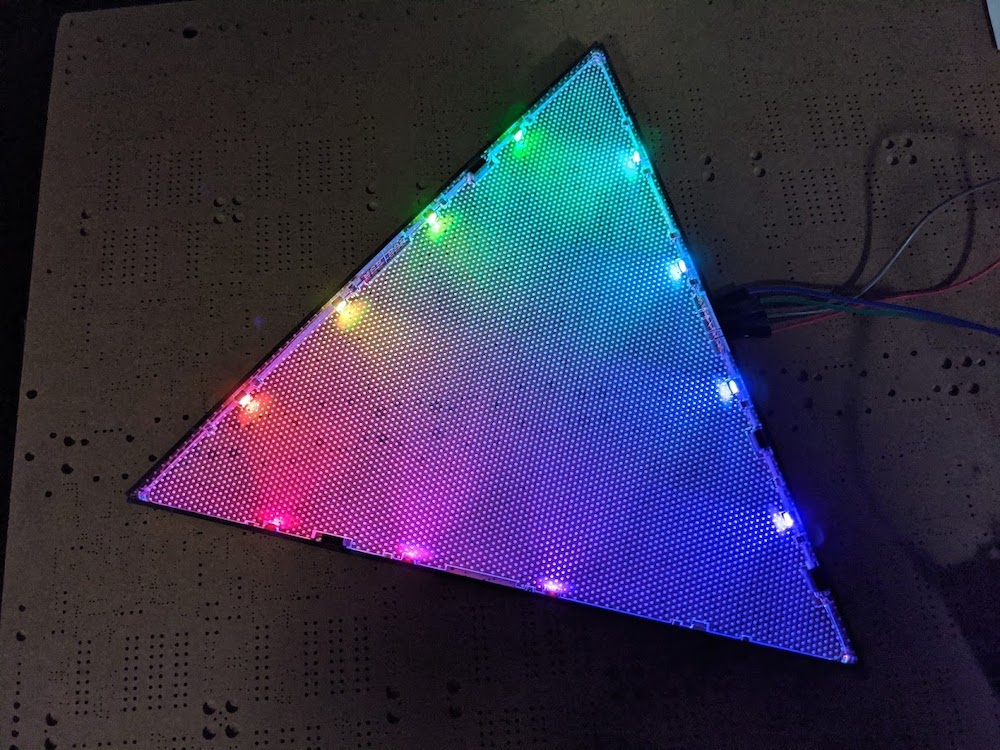

Laser Cutting

Laser cutting is similar to CNC machining in that a computer-driven cutting tool is used to make parts.

However, laser cutting allows for the production of extremely fine details. Laser cutting is also well suited to certain types of prototypes, like LED diffusers, sheet metal parts, or low-volume production.

Designing Breadboard Electronics

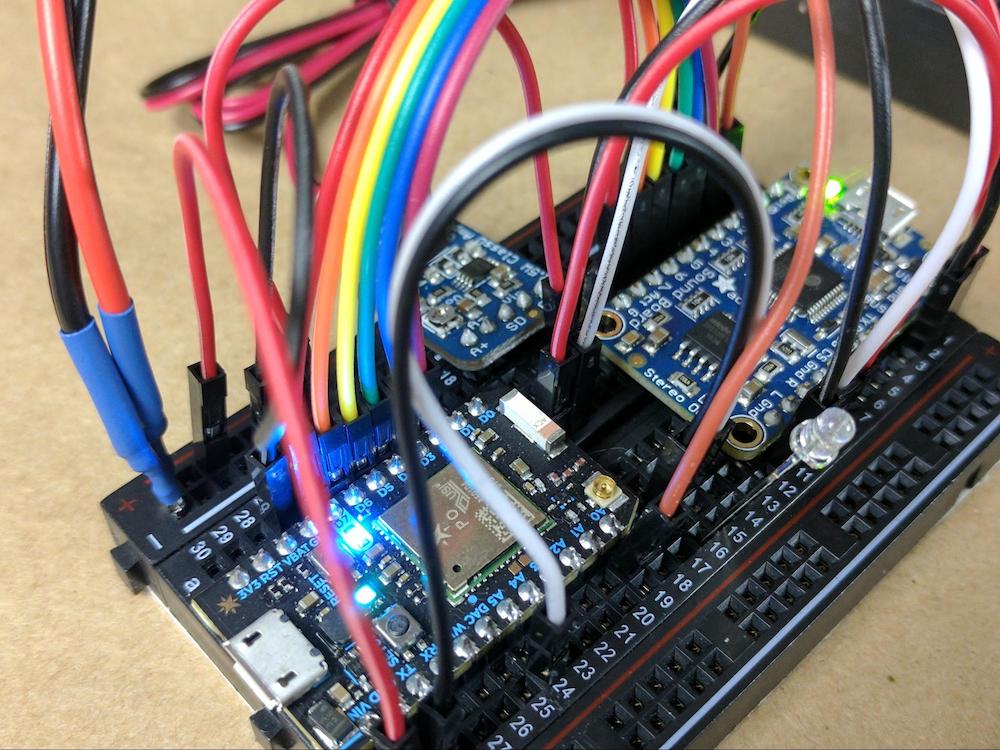

When it comes to prototyping electronics, the process typically begins on a solderless breadboard. A solderless breadboard features a grid of holes into which electrical components can be plugged and electrically connected.

Because no solder is required, parts can quickly and easily be changed or re-oriented. Solderless breadboards are a prototyping technology that allows designers to develop circuit designs more quickly and more cost-effectively than other electronics production methods.

Prototype PCBs

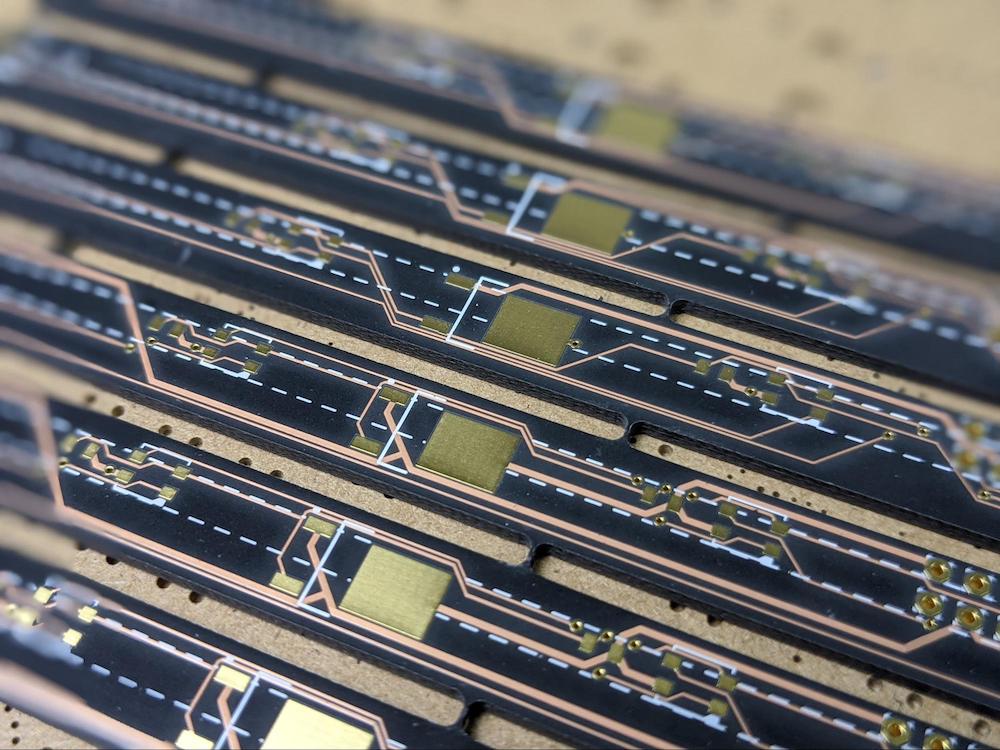

Since solderless breadboards cannot be incorporated into designs, the next phase of electronics prototype development is manufacturing and assembling printed circuit boards.

There are a variety of ways to make PCBs, including CNC milling, quick-turn PCB services, and full-service PCB manufacturers. Just about any electronic product will feature one or more PCBs so prototyping on PCBs means the prototype electronics will be as close as possible to PCBs used in full-scale production.

This article series covers each of these prototyping techniques in-depth to help you decide which technique(s) work best for your idea.