Breadboards are a staple in electronics prototyping, from students to professionals, learn all about it right here!

Technologies like 3D printing, CNC machining, and laser cutting all work for producing prototypes of mechanical parts (or, in some cases, parts to be included in a product for sale). Depending upon the nature of the product you are developing, your product may include electronics as well as mechanical parts. Prototyping electronics involves a whole other set of prototyping technologies.

Breadboards: The Staple of Electronics Prototyping

Often, prototype electronics start out on a solderless breadboard. Breadboards are a staple of electronics development and they have been in use since the 1970s. A solderless breadboard contains a grid of spring-loaded clips under a perforated plastic housing. The clips allow for temporary electrical connections that make breadboards an ideal tool for prototyping.

Breadboards feature a grid of holes into which wires or components can be placed and electrically connected

Breadboard prototypes can range from simple prototypes used for part selection or testing the basic functionality of a design to fully-complete representations of a design that will later be used to design a printed circuit board.

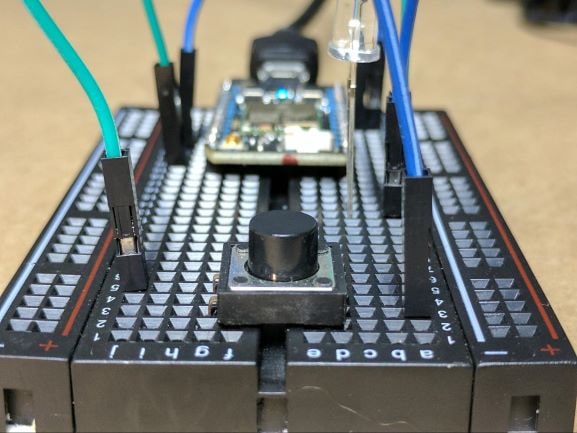

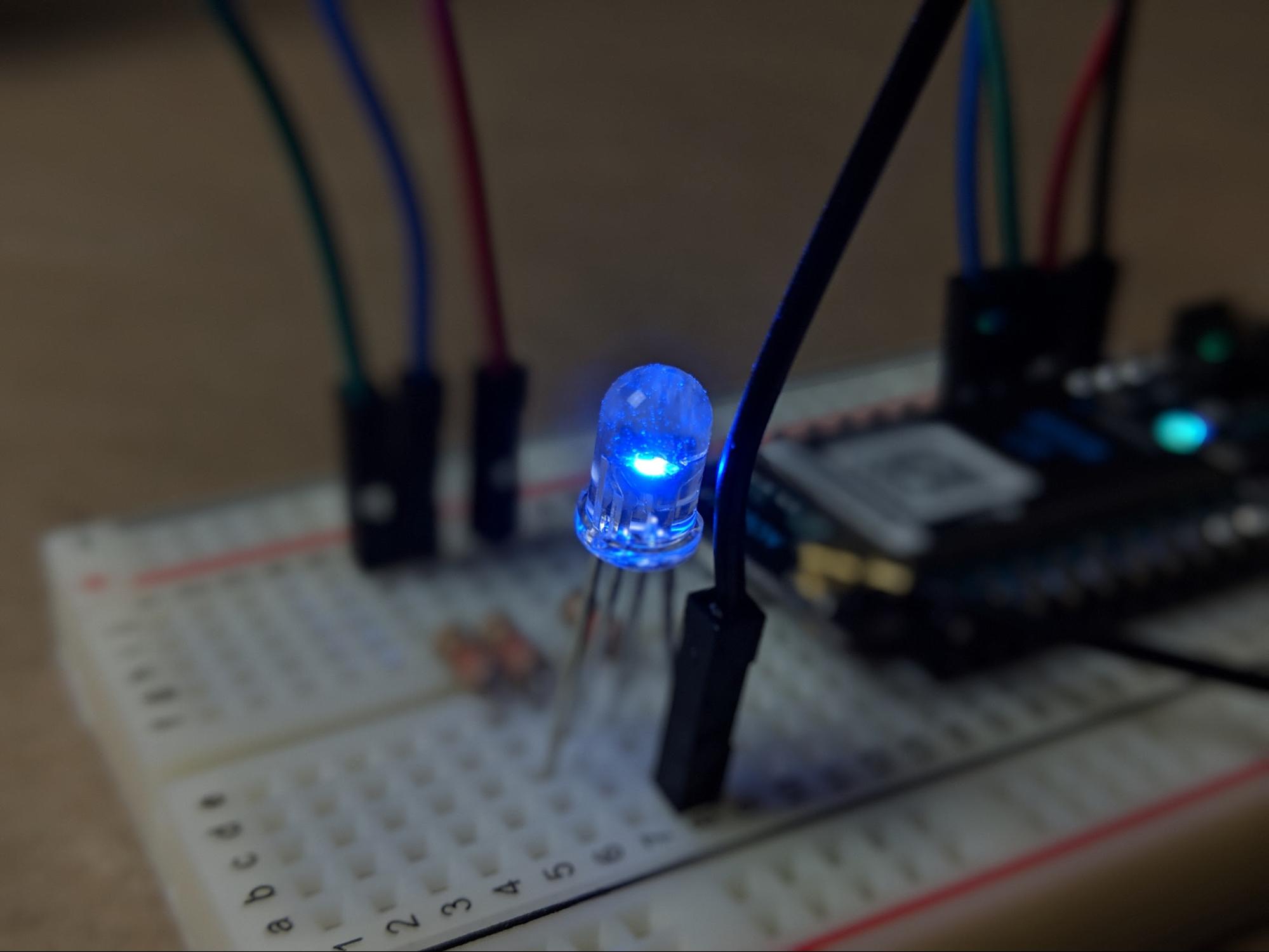

This simple breadboard prototype tests the functionality of a button.

The Benefits of Prototyping Electronics With a Solderless Breadboard

There are several benefits to using solderless breadboards for prototyping electronics. The first is flexibility. Breadboards allow parts to be plugged in and removed from the circuit with ease. This makes experimenting with various circuit designs or components quick and easy. This flexibility allows multiple schematic prototypes to be tested in short order and with minimal equipment.

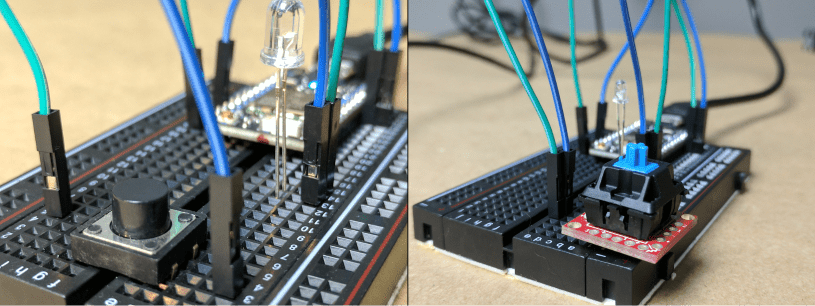

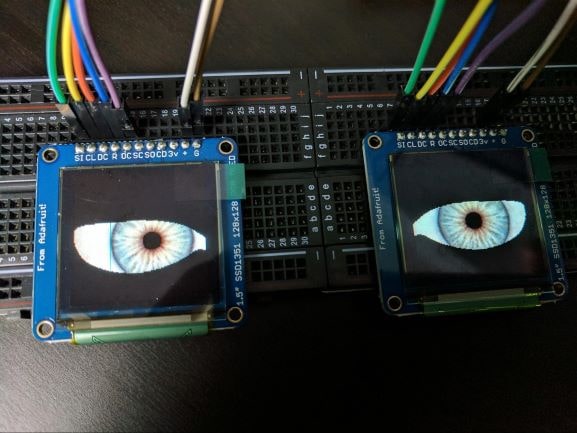

In this image, breadboard prototypes are used to test two different types of buttons for an electronics design

The second benefit of prototyping with breadboards is that it is a low-cost technology. Making printed circuit board prototypes is not too costly, but between the cost of the PCBs themselves and the cost to have them shipped, usually from overseas, it is far cheaper to develop a circuit on a breadboard. This is especially the case when multiple iterations on a circuit are needed to perfect the design.

The cost of producing several PCB prototypes can add up to a significant investment of both money and time, but the cost to produce several prototype designs on a breadboard is minimal.

Downsides to Prototyping With Breadboards

On the other hand, there are a couple of downsides to prototyping on breadboards as well.

The most significant is the selection of available parts. Solderless breadboards only work with through-hole (PTH) components. Printed circuit boards typically use mostly surface-mount (SMD) components.

Because surface mount components cannot be directly plugged into a breadboard, it can be difficult to make a breadboard prototype that translates directly to a PCB. Therefore, a circuit design can function perfectly on a breadboard, but the transition to surface mount components on a PCB can introduce defects into the design.

In some cases, certain components necessary for your electronics design may not be available at all in a breadboard-friendly package.

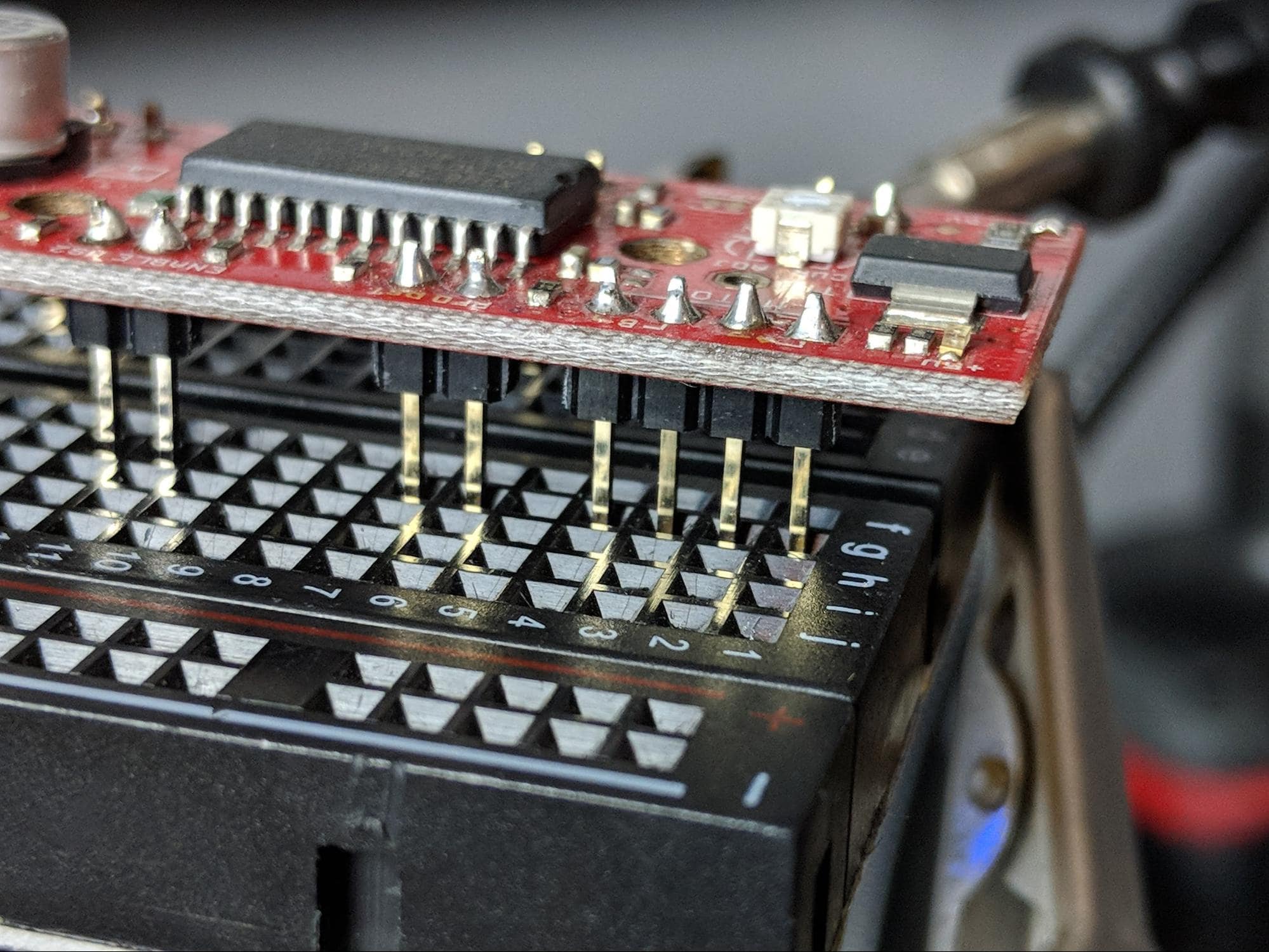

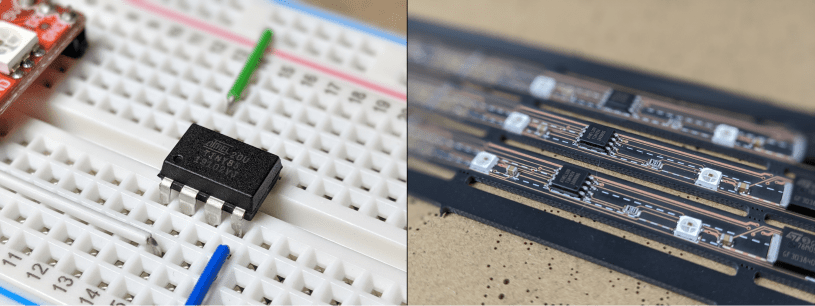

The microcontrollers on both these chips are Attiny85s. The one on the left is a breadboard-compatible PTH component, the one on the right is an SMD component

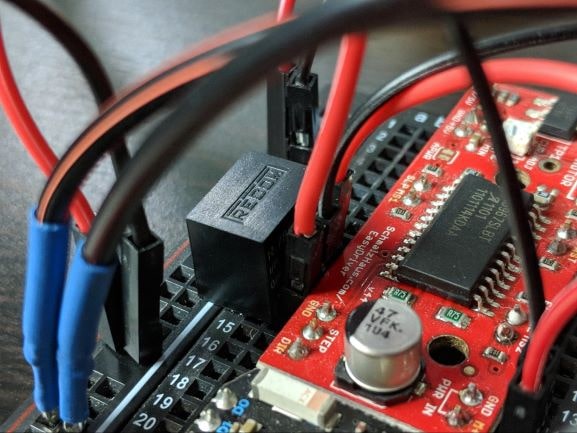

Thankfully, to help alleviate this issue, there are several vendors who offer "breakout boards" for common SMD components. A breakout board is a small PCB that is essentially an adapter allowing SMD components to be connected to a breadboard. The biggest sources for these kinds of boards are Adafruit and SparkFun.

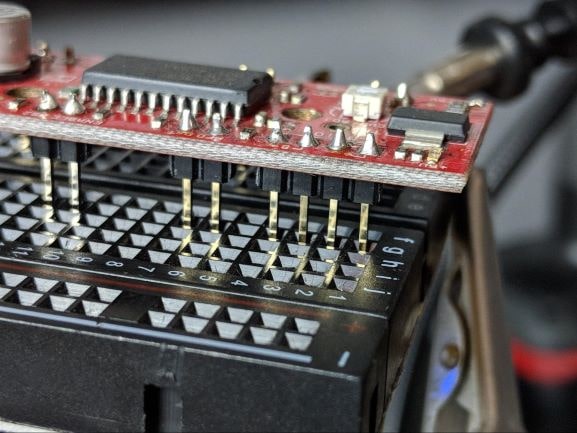

This image shows a breakout board for an H-bridge motor driver (the large chip on top of the board). This is an SMD component that cannot ordinarily be used on a breadboard

The other drawback to using breadboards for prototyping is that they can only, realistically, be used for prototyping.

Unlike CNC machining, laser cutting, and even 3D printing, all of which can be used for prototyping or for manufacturing, breadboards are not suitable for use in finalized product designs. Solderless breadboards are an excellent prototyping tool but for production, the circuit design needs to be translated onto a PCB.

Final Thoughts of Prototyping Electronics With a Breadboard

Creating prototype circuits on a breadboard is often the first phase of developing electronics for a product.

Solderless breadboards allow designers to quickly and easily connect parts without soldering. This means breadboards can be used to create and modify circuits extremely quickly in order to prototype various circuit designs or test different electrical components.

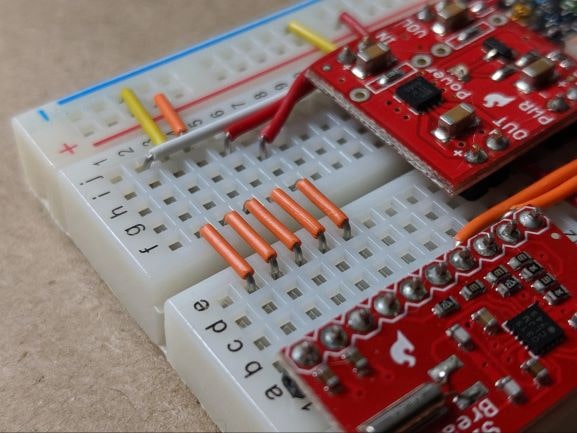

Breadboard prototypes are extremely useful for quickly prototyping different circuit designs and for testing different component choices. In this photo, a breadboard prototype is being used to test different switching voltage regulators for an IoT project

Prototypes built on solderless breadboards are typically translated onto printed circuit boards for further prototyping and for integrating the electronics into a finished product. The major downside to prototyping with a solderless breadboard is that only through-hole components can be connected on a breadboard.

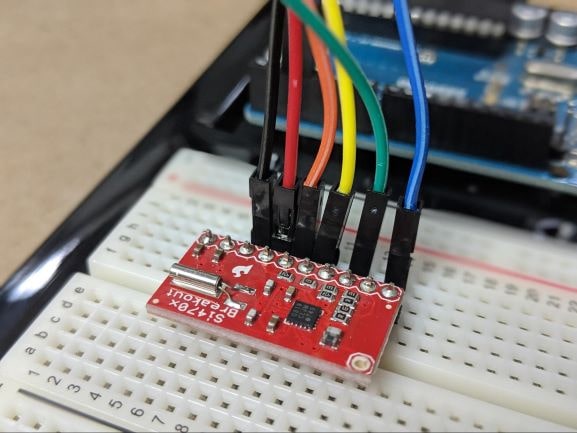

Printed circuit boards use surface mount components as much as possible in order to reduce manufacturing costs. However, many surface mount components are available in through-hole versions, or else breakout boards can be used to interface a surface-mount component with a breadboard.

This photo shows a breakout board that allows the small chip on the board to be connected with other components on a breadboard

Ultimately, circuits developed on a solderless breadboard are used to create printed circuit boards for manufacturing.